Method for detecting faulty operation of gas blower driven by DC motor

A technology of DC motors and electric motors, which is applied in the direction of motor control, motor generator testing, and transmission machinery dedicated to glass blowing machines. It can solve problems such as increased bearing friction, decreased magnet strength, and weakened magnetic field to prevent excessive heating. , reducing the effect of the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

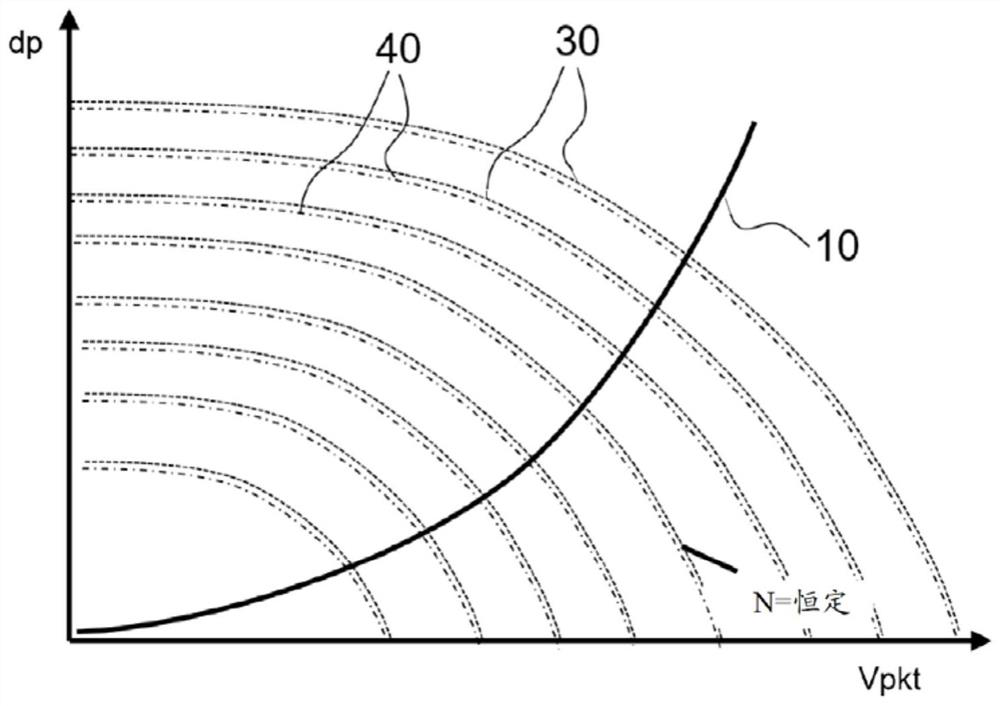

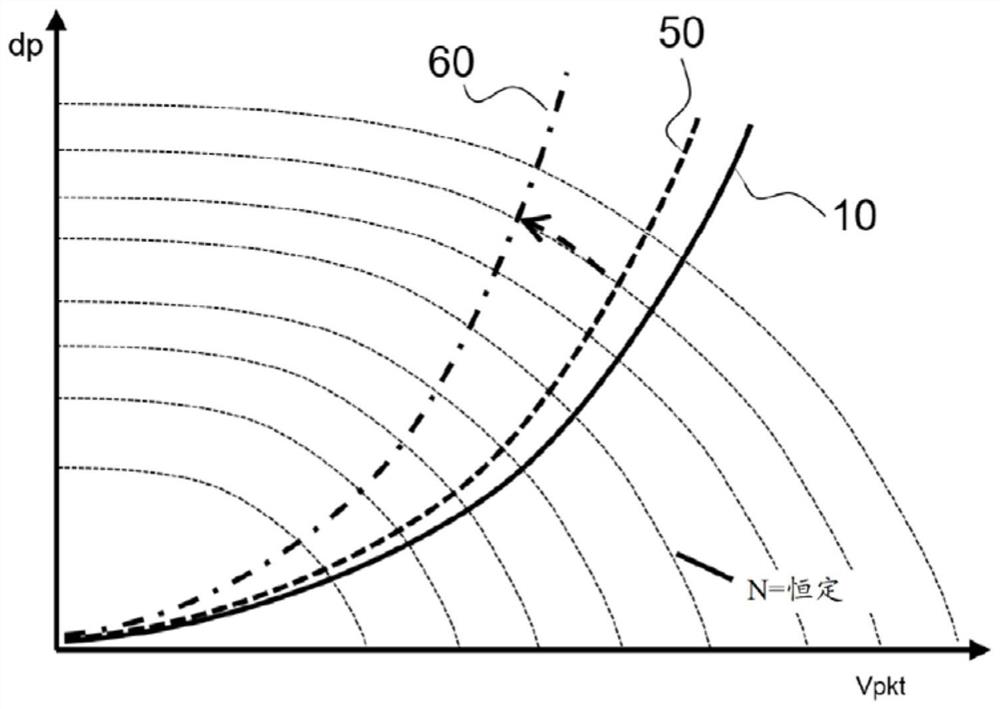

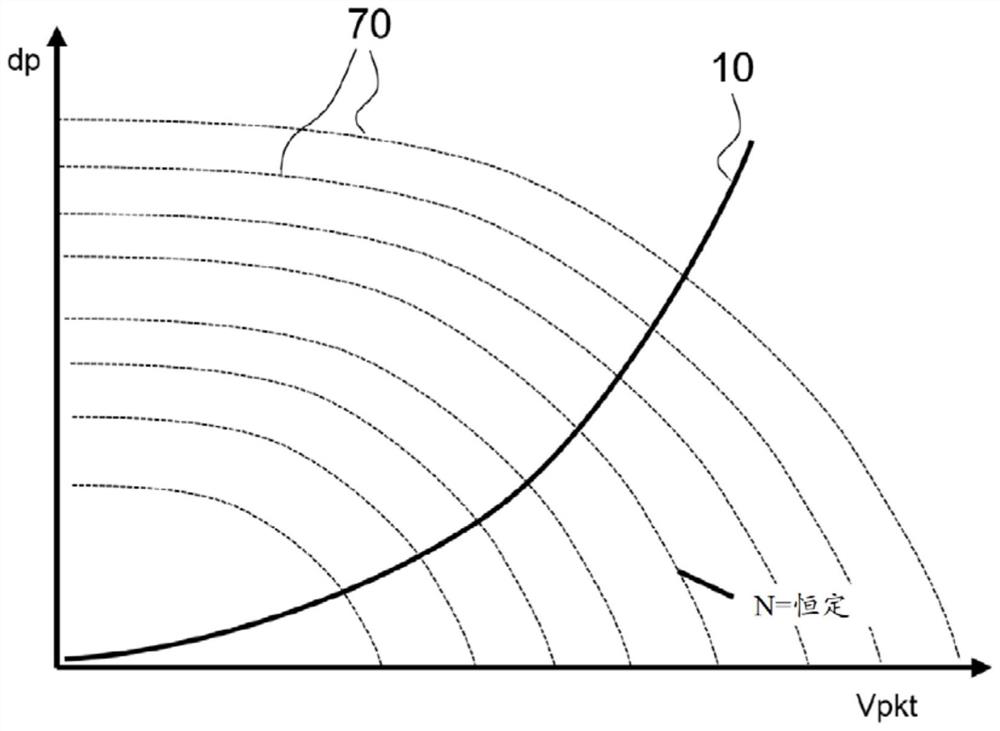

[0022] Figure 1 to Figure 3 The graphs respectively show the fan characteristic curve and the plant characteristic curve of a gas fan formed as a radial fan in the presence of various defect types as influencing variables, wherein the ordinate is the boost dp, and the abscissa is the delivery volume flow Vpkt.

[0023] figure 1 The disadvantageous case of a change in air density is shown schematically as an example. The plant characteristic curve 10 (also called "system characteristic curve") is simply assumed to be constant. Furthermore, the reference characteristic curve 30 and the lower air density characteristic curve 40 are each represented as a reference variable at a constant rotational speed N.

[0024] figure 2 shows the rising pressure loss due to a system-related defect situation (such as a clogged exhaust pipe on the heating boiler or a dirty heat exchanger) that makes the nominal plant characteristic curve 10 when the gas blower starts with the heating boiler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com