Compact large-penetration plasma arc welding gun

A plasma arc, compact technology, applied in the field of ion arc welding, can solve the problems of damage to the water cooling structure of the gas cover, narrow field of vision in the welding area, danger, etc., achieve smooth and continuous air flow channels, reduce production costs, and have no structural mutation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

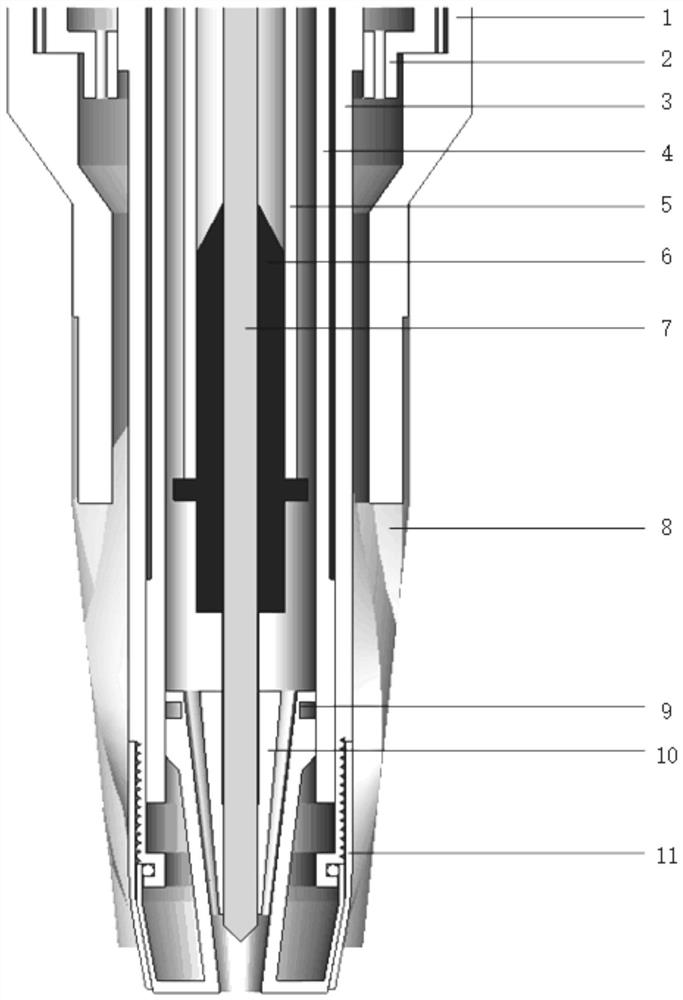

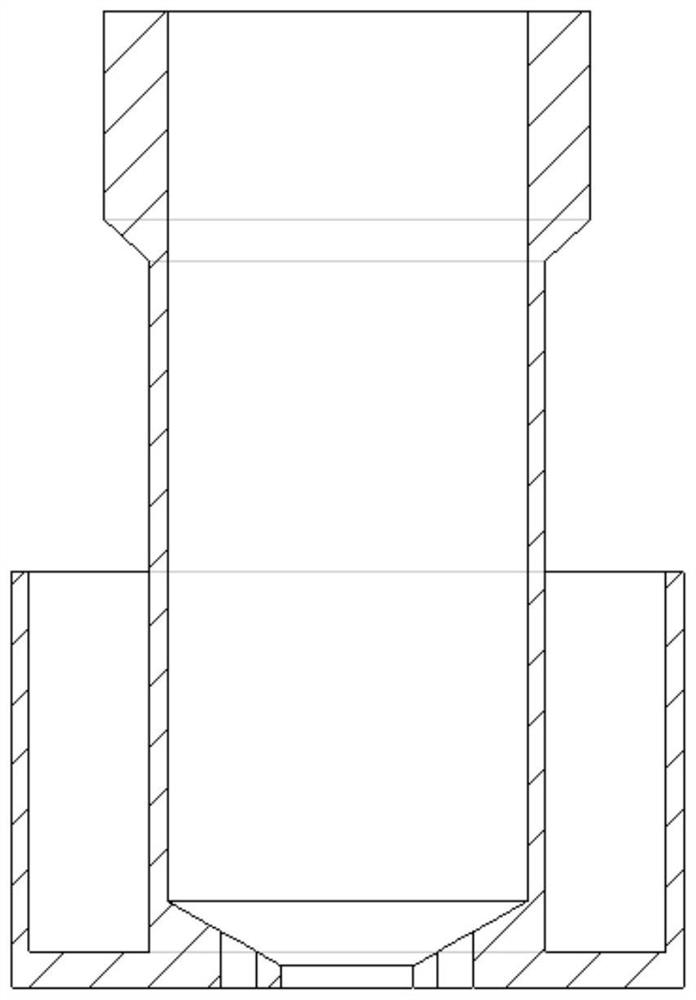

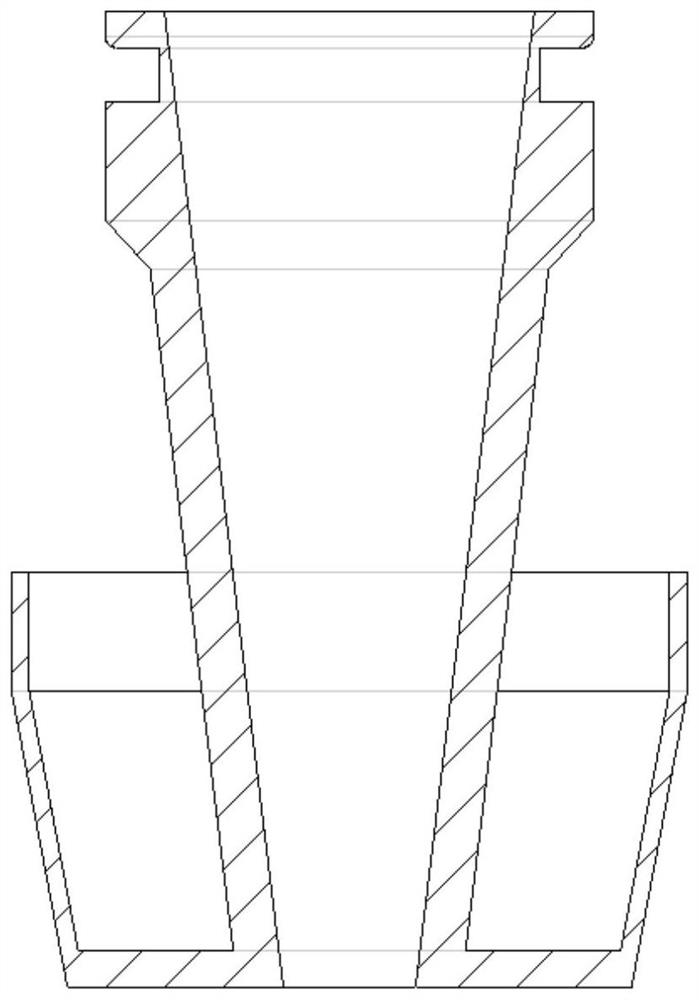

[0041] A compact high penetration plasma arc torch such as figure 1 As shown, the end of the torch consists of tungsten pole, gas-conducting ceramic sleeve, water-cooled copper nozzle, gas shield, and gas-hood head from inside to outside, in which the ion gas passes through the gas-guiding porcelain sleeve and water-cooled copper nozzle, and the shielding gas passes through the gas-guiding porcelain sleeve and water-cooled copper nozzle The water-cooled copper nozzle passes between the gas shield and the gas shield head.

[0042] The tungsten electrode is connected with the electrode holder through the chuck. There is an insulating sleeve on the outside of the tungsten electrode. A nozzle seat is arranged on the outside of the insulating sleeve. A water-cooled copper nozzle is installed on the end of the nozzle seat. A gas hood head is set, and a gas protective diffuser is arranged inside the other end of the gas shield.

[0043]The inner wall of the water-cooled copper nozzl...

Embodiment 2

[0049] A compact large-penetration plasma arc welding torch, the structure of which is as described in Embodiment 1, the difference is that the number of diversion grooves is three.

Embodiment 3

[0051] A compact large-penetration plasma arc welding torch has the same structure as that described in Embodiment 1, except that the number of diversion grooves is 15.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com