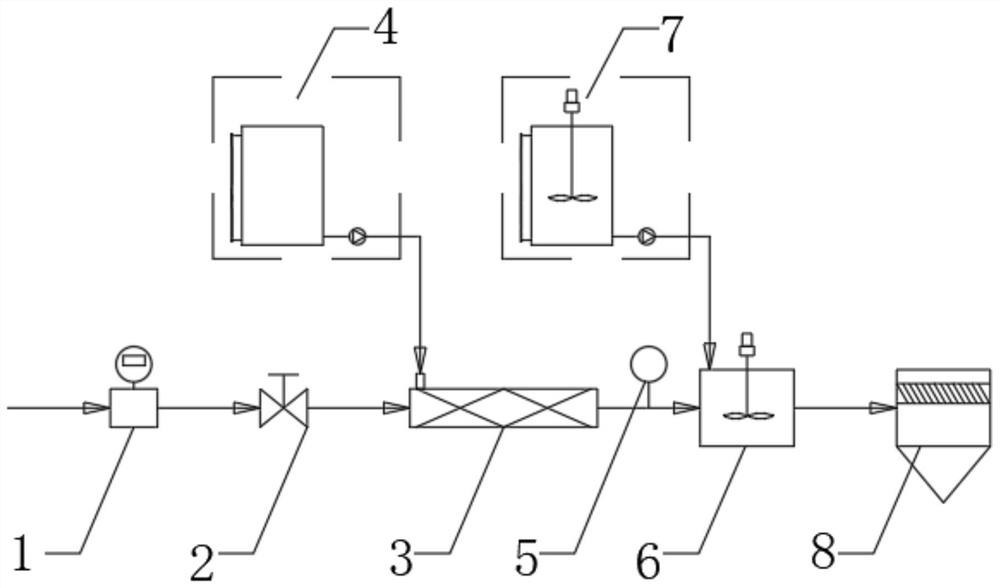

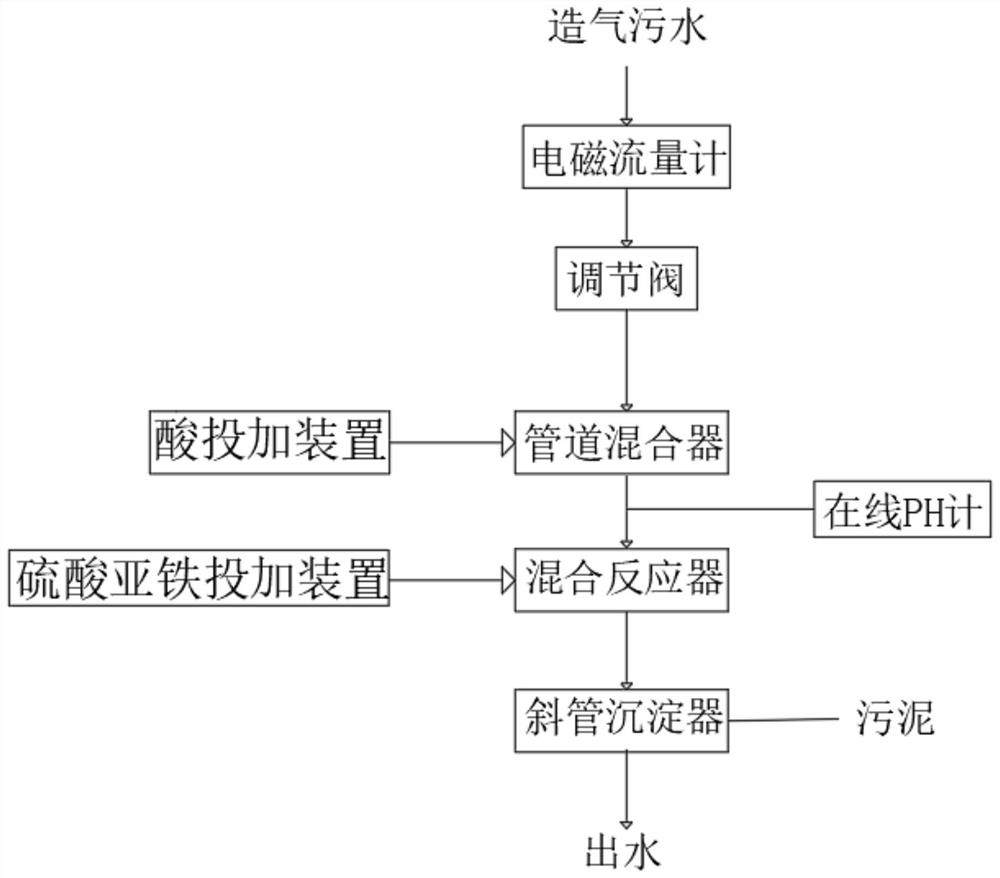

Synchronous desulfurization and decyanation method and device for gas-making sewage of coal chemical industry

A technology for desulfurization and decyanation and coal chemical industry, which is applied in the field of synchronous desulfurization and decyanation of coal chemical gas-making sewage and its device field, which can solve the problems of complex system equipment configuration, high operation and management requirements, and complex components of gas-making sewage, and eliminate Biological toxicity, guaranteed normal operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0036] Example 1: A company's gas-making sewage pretreatment project, the treated water volume: 60m 3 / h.

[0037] Comparison of water quality before and after treatment of gas-making sewage by this technology:

[0038] serial number index unit before processing after treatment Removal rate 1 pH 8-9 6.2-6.5 -- 2 Sulfide mg / L ≤40 ≤5 ≥87.5% 3 cyanide mg / L ≤30 ≤3 ≥90% 4 suspended matter mg / L ≤100 ≤30 ≥70% 5 COD mg / L ≤1500 ≤1200 ≥20%

[0039] The sulfide of gas-making sewage before treatment in this project: 40mg / L, cyanide: 30mg / L, after using this technology to treat, the system effluent sulfide: 5mg / L, cyanide: 3mg / L, sulfide and cyanide The removal rates were 87.5% and 90%, respectively. The treated gas-generating sewage no longer has an inhibitory effect on the activated sludge microorganisms in the subsequent biological treatment unit, and the subsequent biological treatment unit operates stably....

example 2

[0040] Example 2: Gas-making sewage pretreatment project of company B, water volume to be treated: 100m 3 / h.

[0041] Comparison of water quality before and after treatment of gas-making sewage by this technology:

[0042] serial number index unit before processing after treatment Removal rate 1 pH 6-9 6.2-6.5 -- 2 Sulfide mg / L ≤50 ≤5 ≥90% 3 cyanide mg / L ≤30 ≤3 ≥90% 4 suspended matter mg / L ≤200 ≤60 ≥80% 5 COD mg / L ≤3000 ≤2700 ≥10%

[0043] Before the treatment of this project, the sulfide of gas-making sewage: 50mg / L, cyanide: 30mg / L, after using this technology to treat, the sulfide of the system effluent: 5mg / L, cyanide: 3mg / L, the content of sulfide and cyanide The removal rates are 90% and 90%, respectively. The treated gas-generating sewage no longer has an inhibitory effect on the activated sludge microorganisms in the subsequent biological treatment unit, and the subsequent biological treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com