Raw material for preparing matchstick friction layer and method for coating glass surface with same

A technology of friction layer and match, which is applied in the field of raw materials for preparing match friction layer, can solve the problems that the match friction layer does not have fluorescent function, cannot facilitate the use of glass products, and the match friction layer is easy to fall off, etc., so as to achieve high practicability and improve Practicality, effect of improving adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0023] As a preferred embodiment of the present invention, the adhesive is a liquid adhesive.

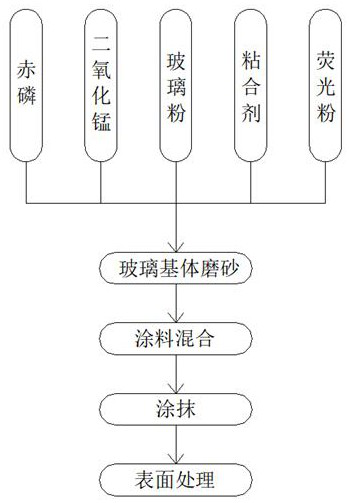

[0024] A method for coating the raw material of the match friction layer on the glass surface, the specific steps are as follows:

[0025] Step 1: Frosting the glass substrate; according to the needs, process the frosted area on the glass substrate where the match friction layer is needed. In the frosting process, first design the shape of the match frosted layer and mark the processing area on the glass product. A shallow groove with a certain depth is processed inside, and a certain number of fixed posts in the shape of inverted truncated cones are retained in the shallow groove. The length of the fixed posts is less than the depth of the shallow groove. The exposed surface in the processing area is frosted. After processing is completed , Clean the frosted area and remove the glass slag to facilitate the adhesion of the match friction layer. The frosted treatment and the inverted trun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com