Protective coating material for ships, naval vessels and offshore drilling platforms, and preparation method thereof

A technology for drilling platforms and ships, applied in the field of coatings, can solve problems such as hull and platform corrosion, coating layer damage, economic losses, etc., and achieve the effects of prolonging the life of coatings, preventing coatings from burning, and slowing down the aging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

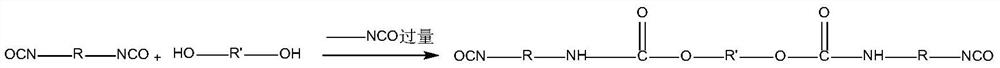

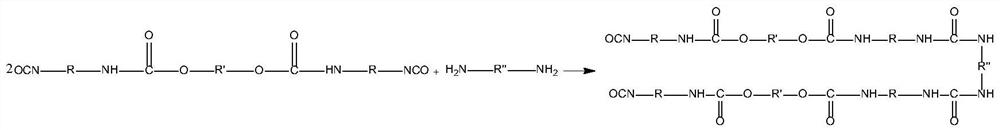

Method used

Image

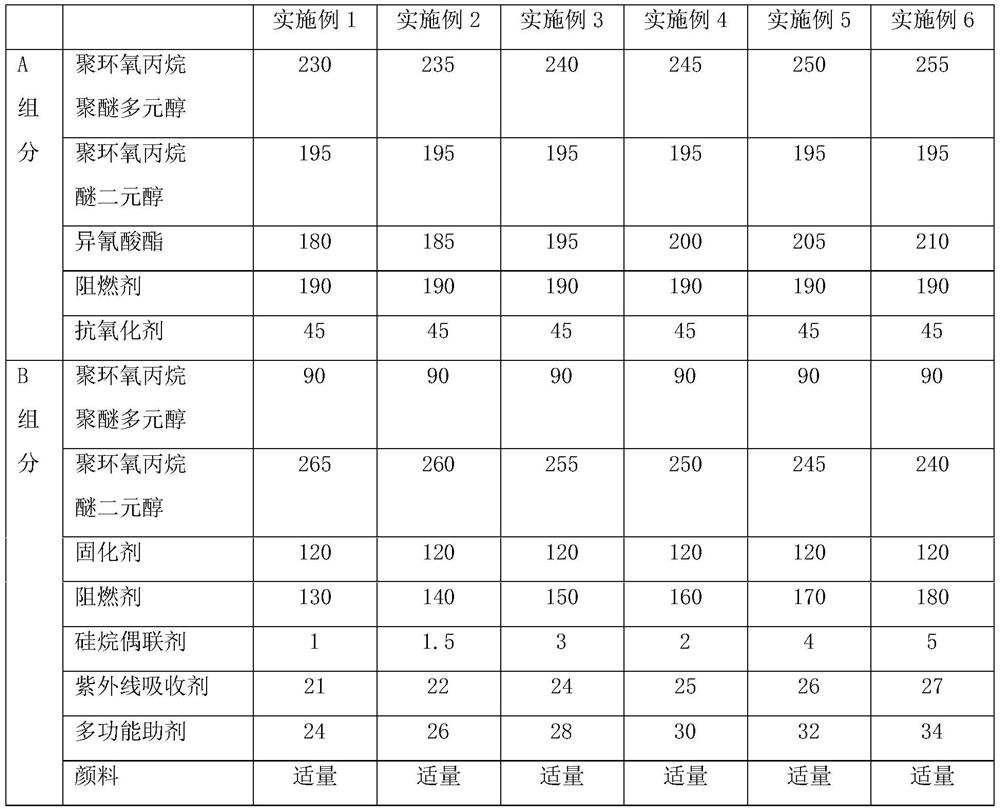

Examples

preparation example Construction

[0048]In the preparation method of the above-mentioned protective coating material for ships, warships and offshore drilling platforms, the preparation method of component A comprises the following steps:

[0049] Step 1. Turn on the vacuum system to make the vacuum in the reactor reach -0.09MPa. Open the stirring system of the reactor, open the suction valve at the bottom of the reactor, absorb the polypropylene oxide polyether polyol MN-3050DF and polypropylene oxide ether glycol DL-4000D according to the formula, and start the heating system of the reactor , heating while stirring, so that the temperature of the material is raised to 80 ° C, and the viscosity of the polypropylene oxide polyether polyol and the polypropylene oxide ether glycol is reduced.

[0050] Step 2. Then turn on the vacuum system to make the vacuum degree in the reactor reach -0.09MPa, and then open the suction valve at the bottom of the reactor to absorb the flame retardant and antioxidant according t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com