Polyurethane patch adhesive and preparation method thereof

A technology of patch glue and polyurethane, applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc. Short curing time, low curing temperature, and the effect of enhancing joint reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

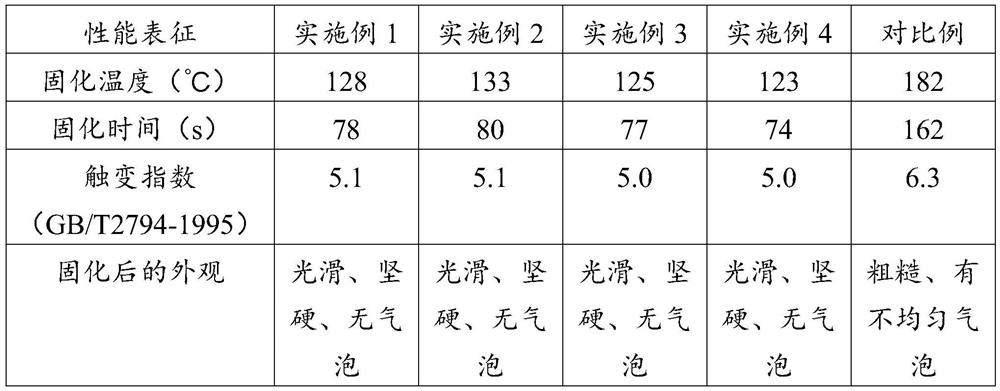

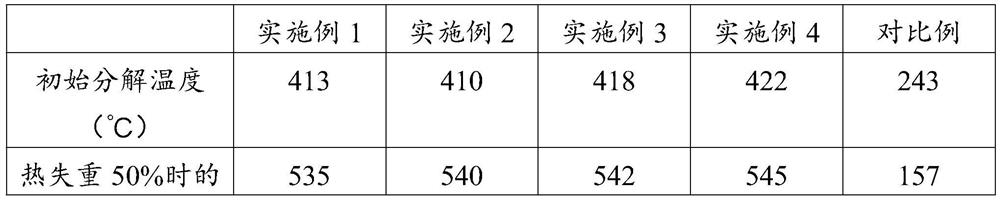

Examples

Embodiment 1

[0047] A kind of polyurethane patch glue, is made up of following raw material according to mass percentage:

[0048] Polyether TPU 35%, polyester TPU 45%, tackifying resin 5%, coupling agent 0.5%, antioxidant 3%, flame retardant 3%, initiator 0.5%, inorganic filler 6%, epoxy Curing agent 2%.

[0049] The coupling agent is a titanate coupling agent NDZ-201, and the peel strength of the polyurethane patch adhesive added with the titanate coupling agent NDZ-201 is greatly improved after pasting, and there is still a high Peel strength. Due to the existence of amphoteric groups in the coupling agent, the hydrophilic group is more conducive to bonding, and the lipophilic (hydrophobic) group is hydrophobic, repels water and is not easy to immerse between the polyurethane patch adhesive and the adhesive product.

[0050] The tackifying resin is compounded by terpene resin and hydrogenated C5 resin according to the ratio of 15:1. The combination of terpene resin and hydrogenated C...

Embodiment 2

[0060] A kind of polyurethane patch glue, is made up of following raw material according to mass percentage:

[0061] Polyether TPU 45%, polyester TPU 15.3%, tackifying resin 12%, coupling agent 1%, antioxidant 6%, flame retardant 6%, initiator 1.2%, inorganic filler 10%, epoxy Curing agent 3.5%.

[0062] The coupling agent is a titanate coupling agent NDZ-201, and the peel strength of the polyurethane patch adhesive added with the titanate coupling agent NDZ-201 is greatly improved after pasting, and there is still a high Peel strength. Due to the existence of amphoteric groups in the coupling agent, the hydrophilic group is more conducive to bonding, and the lipophilic (hydrophobic) group is hydrophobic, repels water and is not easy to immerse between the polyurethane patch adhesive and the adhesive product.

[0063] The tackifying resin is compounded by terpene resin and hydrogenated C5 resin according to the ratio of 18:1. The combination of terpene resin and hydrogenat...

Embodiment 3

[0073] A kind of polyurethane patch glue, is made up of following raw material according to mass percentage:

[0074] Polyether TPU 40%, polyester TPU 30.7%, tackifying resin 8%, coupling agent 0.8%, antioxidant 4.5%, flame retardant 4.5%, initiator 0.8%, inorganic filler 8%, epoxy Curing agent 2.7%.

[0075] The coupling agent is a titanate coupling agent NDZ-201, and the peel strength of the polyurethane patch adhesive added with the titanate coupling agent NDZ-201 is greatly improved after pasting, and there is still a high Peel strength. Due to the existence of amphoteric groups in the coupling agent, the hydrophilic group is more conducive to bonding, and the lipophilic (hydrophobic) group is hydrophobic, repels water and is not easy to immerse between the polyurethane patch adhesive and the adhesive product.

[0076] The tackifying resin is compounded by terpene resin and hydrogenated C5 resin according to the ratio of 16:1. The combination of terpene resin and hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com