Dry distillation device for oil shale processing

A technology of oil shale and carbonization, which is applied in the field of oil shale processing, can solve the problems of blockage of the bottom screen and affect the effect of carbonization, and achieve the effects of avoiding sticking, improving the effect of carbonization, increasing air flow and heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

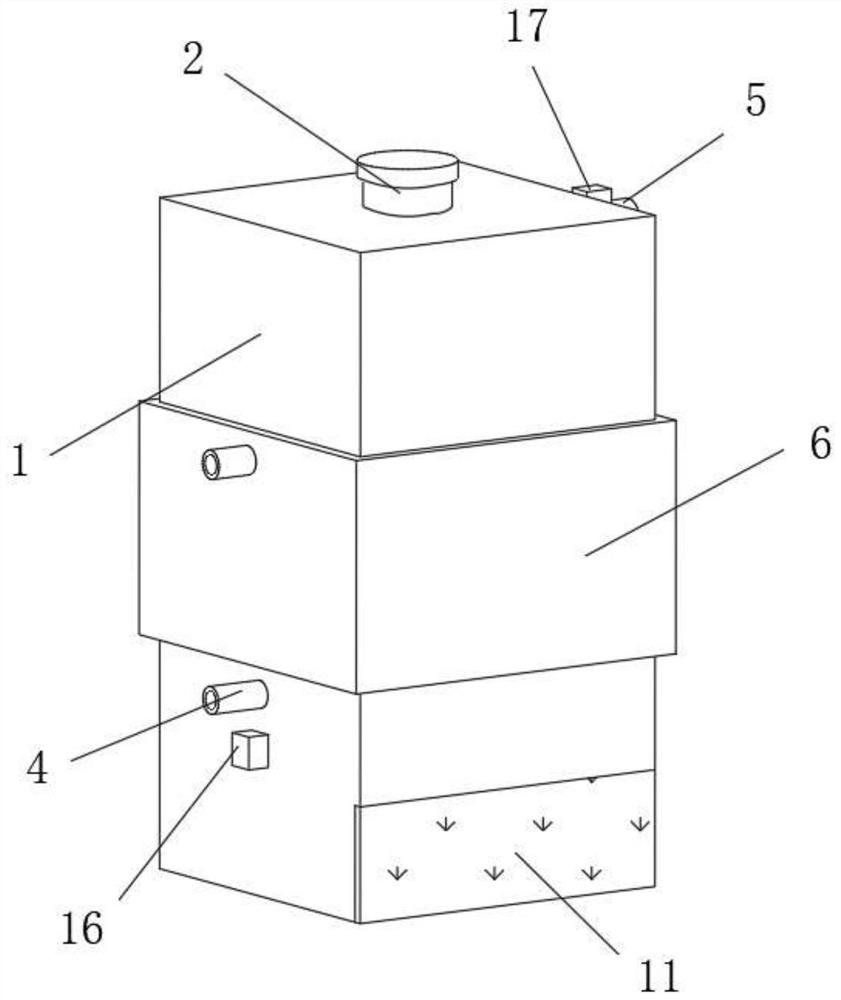

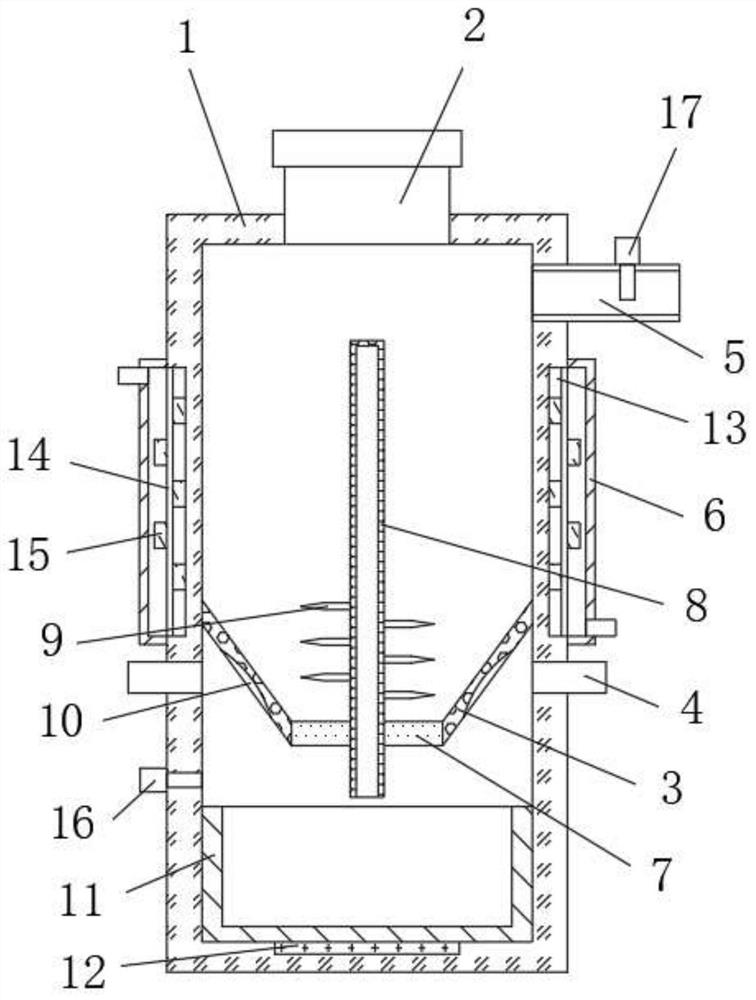

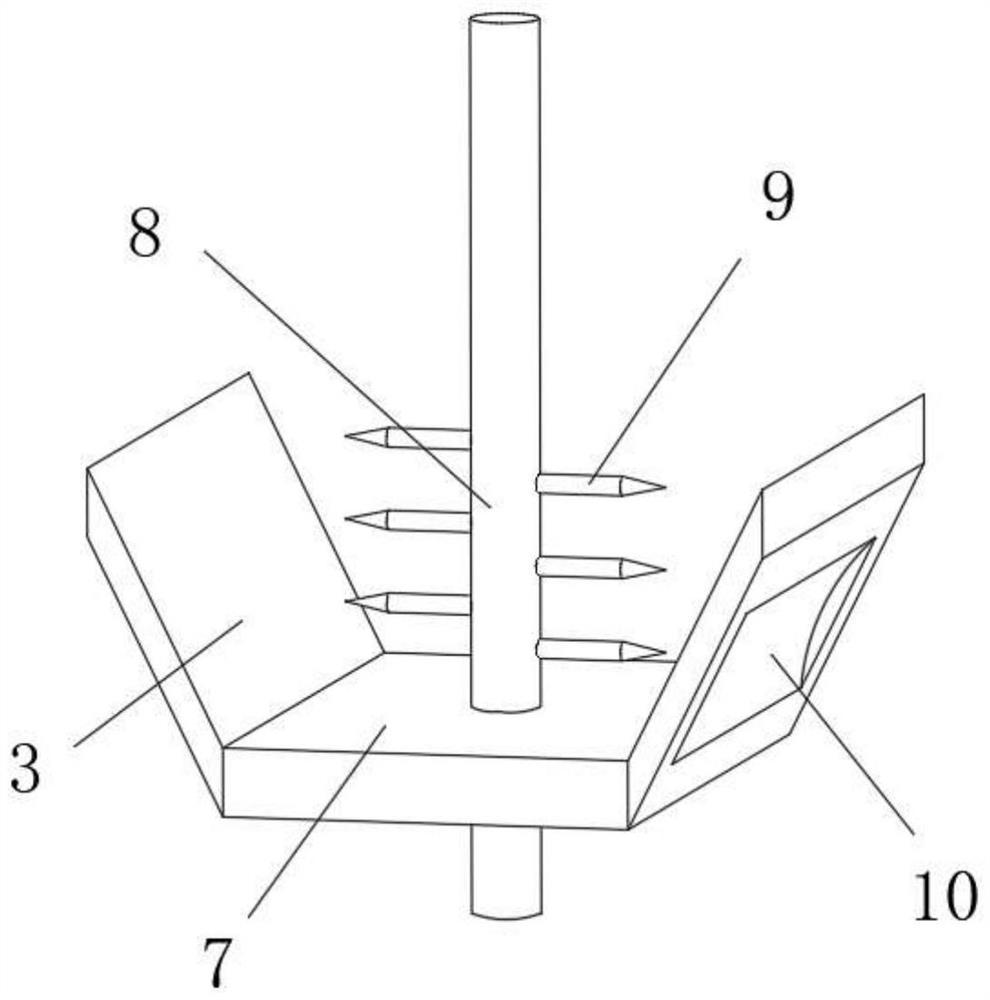

[0028] refer to Figure 1-3 , a retort device for oil shale processing, comprising a retort 1, the top of the retort 1 is provided with a feed pipe 2, the bottom of the retort 1 is provided with a filter plate 3, and the retort 1 is located on the filter plate 3 Air inlet pipe 4 and exhaust pipe 5 are arranged on the bottom and top respectively, the outer wall of retort 1 is located on the top of filter plate 3 and is wrapped with water bath shell 6, the inner wall of retort 1 is arranged in a square structure, and retort 1 is two The bottom of the side inner wall is fixed with an oblique filter plate 3, the filter plate 3 is inclined downward to the side away from the inner wall of the retort 1, and the bottom between the two filter plates 3 is connected with a vibrating screen 7 through a torsion spring An air inlet pipe 4 is fixed at the positions corresponding to the outer walls of both sides of the retort 1 and the screen plate 3 .

[0029] In the present invention, the ...

Embodiment 2

[0034] refer to Figure 4-5, a retort device for oil shale processing. The top of the inner wall of the retort 1 is fixed at the position corresponding to the exhaust pipe 5. A fixed frame 18 with a circular structure is fixed, and the inner wall section of the fixed frame 18 is set to be circular. The fixed frame 18 The inner wall of the guide net 19 is fixed with a cylindrical structure, the outer wall of the guide net 19 is set to an inwardly concave arc structure, and the bottom end of the outer wall of the guide net 19 and the fixed frame 18 pass through the bearing Rotationally connected, and the top of the guide screen 19 is slidingly connected to the top inner wall of the retort 1, and the outer wall of the guide screen 19 is fixed with guide vanes 20 distributed in a circular array, and the guide vanes 20 are arranged in an inclined streamlined structure.

[0035] When in use, use the deflector screen 19 to prevent the dust in the retort 1 from being discharged direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com