Lactobacillus fermentum and application thereof in preparation of conjugated fatty acid

A technology for fermenting lactobacillus and fatty acid, applied in the biological field, can solve the problems of far different isomer content, complex oil composition, low yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

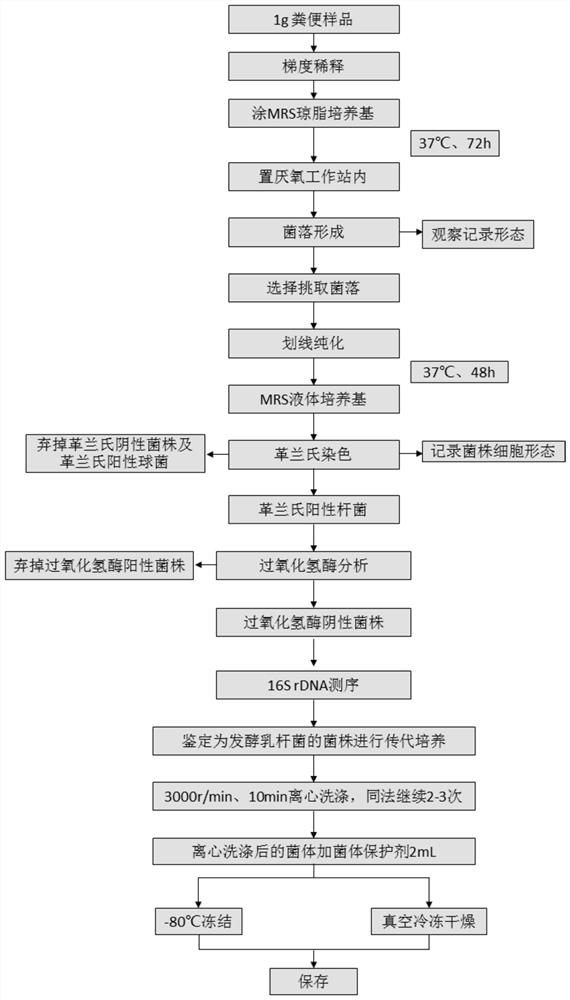

[0041] Example 1: Collection of samples and isolation and identification of Lactobacillus

[0042] 1. Sample collection and separation

[0043] (1) The samples were collected from the feces of a 90-year-old man in Rugao City, Nantong City, Jiangsu Province.

[0044] (2) Take 1g of feces sample, spread the sample on MRS solid medium after serial dilution, place it in an anaerobic environment, and culture it at 37°C for 72 hours, observe and record the colony shape; Cultivate in liquid medium at 37°C for 48 hours, perform Gram staining on the obtained colonies and record the strain morphology; discard the Gram-negative strains and Gram-positive cocci in the colonies, and select the Gram-positive bacilli; After the obtained Gram-positive bacilli were analyzed by catalase, the catalase-positive strains were discarded, and the catalase-negative strains were retained; the resulting strain was identified as Lactobacillus fermentum through 16S rDNA sequencing, and named as Lactobacil...

Embodiment 2

[0060] Embodiment 2: the preparation of the microbial preparation containing lactobacillus fermentum (Lactobacillus fermentum) CCFM1116

[0061] The glycerin tube containing Lactobacillus fermentum CCFM1116 was taken out from the -80°C refrigerator, and 200-600 μL of Lactobacillus fermentum CCFM1116 bacterial liquid was inoculated into 10-30 mL of MRS liquid medium. Under anaerobic environment, 37 Activate 2 to 3 generations at ℃ until Lactobacillus fermentum (Lactobacillusfermentum) CCFM1116 reaches 1×10 8 When the number of viable bacteria is above cfu / mL, centrifuge at 5000-10000rpm for 10-20min, remove the supernatant, and then add buffer (normal saline or 0.2M phosphate buffer with a pH value of 7) and Cryoprotectant (15%-20% (w / v) sucrose solution), the concentration of the cells should not be lower than 1×10 9 cfu / mL, vacuum freeze-drying to obtain solid bacterial agent.

Embodiment 3

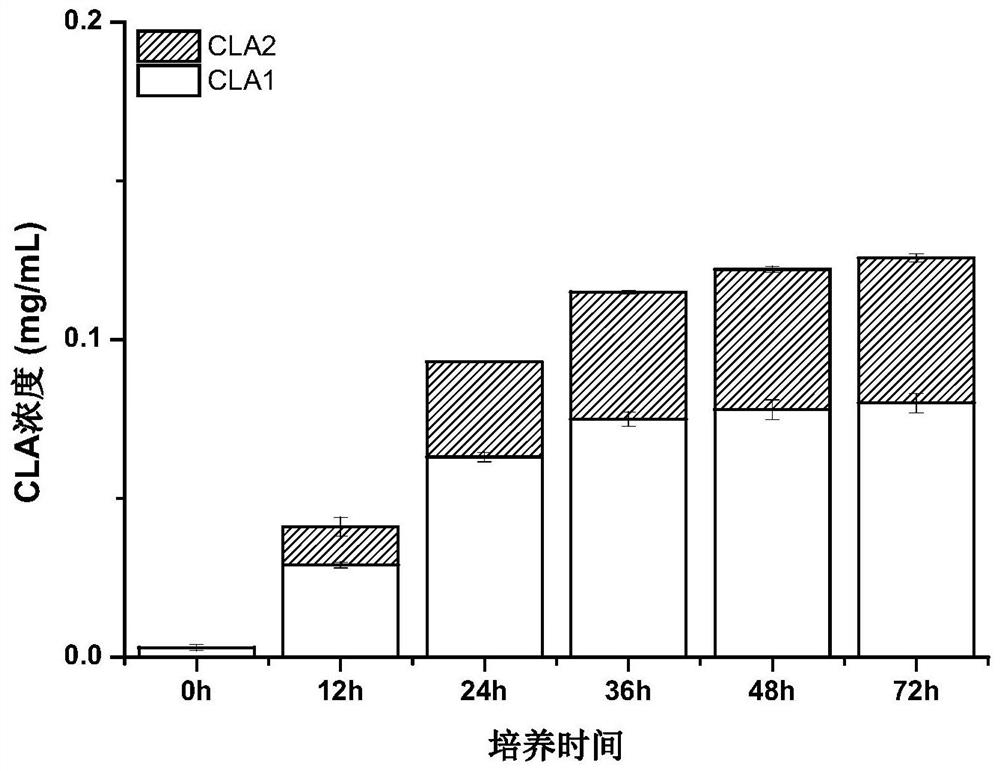

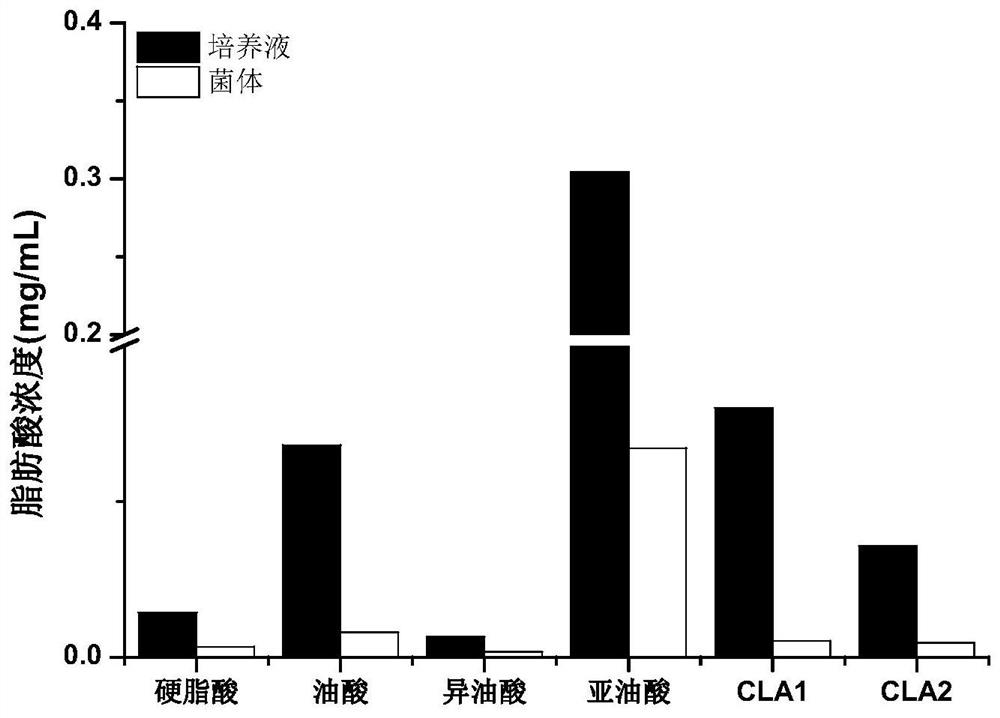

[0062] Example 3: Application of Lactobacillus fermentum CCFM1116 in the preparation of conjugated linoleic acid

[0063] Specific steps are as follows:

[0064] (1) Strain activation

[0065] Take out the glycerin tube containing Lactobacillus fermentum (Lactobacillus fermentum) CCFM1116 from the -80°C refrigerator, take out the bacterial solution and streak it on the MRS solid medium, and culture it at 37°C for 48h in an anaerobic environment; pick the grown single colony and inoculate it on In the MRS liquid medium, cultured at 37° C. for 48 hours under anaerobic environment, and continuously activated for 3 generations to obtain the bacterial liquid.

[0066] (2) Preparation of linoleic acid mother liquor

[0067] Weigh 300mg of linoleic acid (LA) and 200mg of Tween-80, dissolve them in water and dilute to 10mL, stir and emulsify fully, filter and sterilize through a 0.45μm sterile filter membrane to obtain linoleic acid with a concentration of 0.48mg / mL Acid mother liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com