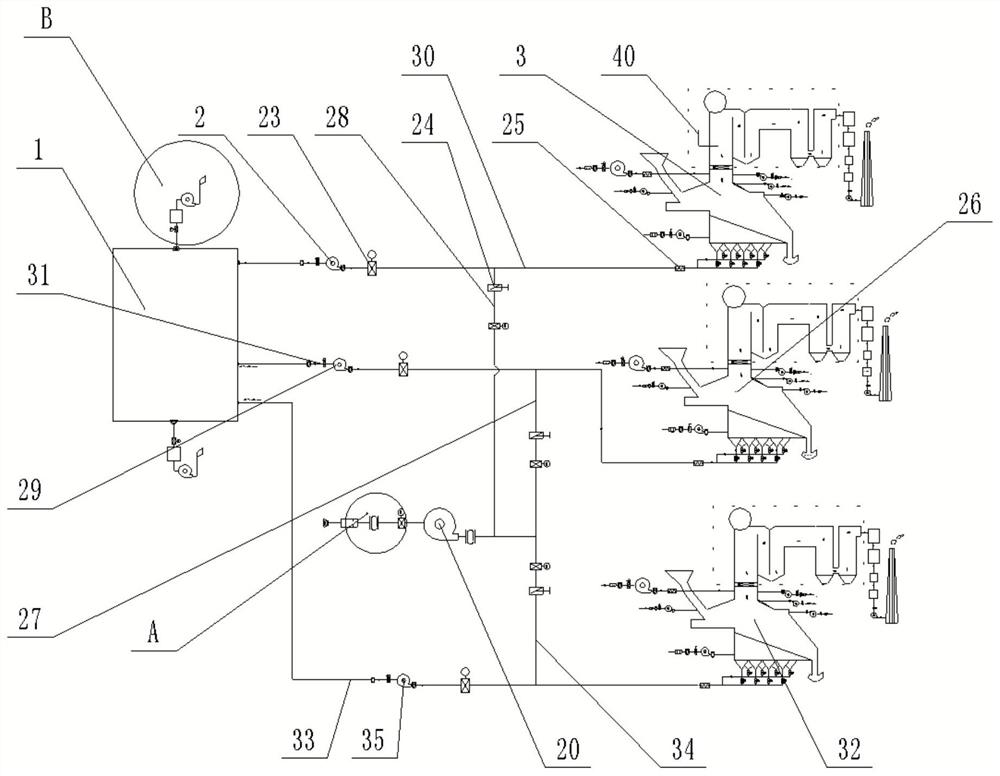

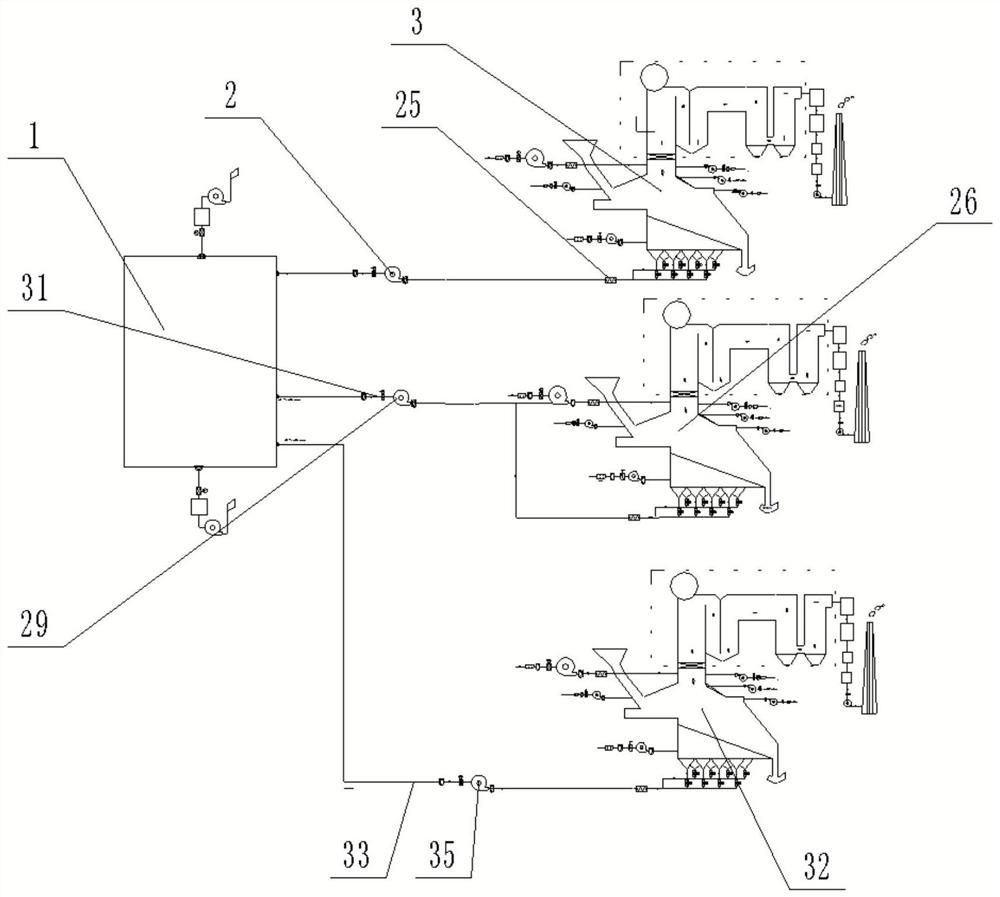

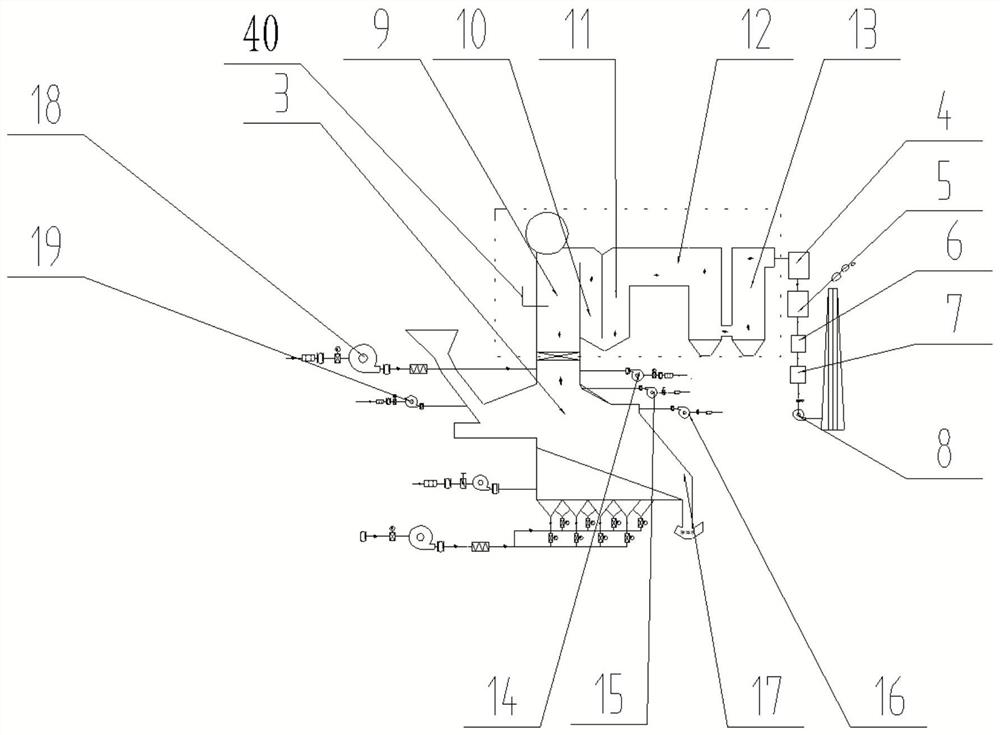

Three-boiler type municipal domestic waste incinerator air and flue gas system

A technology for urban domestic waste and incinerators, applied in the field of waste incineration treatment systems, can solve the problems of affecting the service life of the grate, hidden dangers of environmental pollution, and incomplete decomposition of odors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Such as Figure 1~5As shown, the air-smoke system of a one-pit three-furnace municipal solid waste incinerator includes a garbage storage pit 1, which is connected to a primary fan I2, a primary air preheater I25, and an incineration boiler I3 through a pipeline I30 in sequence; The pit is connected with the primary fan II, the primary air preheater II, and the incineration boiler II26 in turn through the pipeline II31; The deodorizing device inlet filter screen 39, the deodorizing device inlet electric door 36, the gac suction device 37 and the explosion-proof type deodorizing blower fan 38 connected successively, the deodorizing device I, the deodorizing device II are installed in the garbage storage pit 1 both sides, its The function is to start the deodorizing fan device when the garbage pit incinerator is completely out of operation, maintain the negative pressure of the garbage pit, and prevent the overflow of the garbage pit odor; the garbage storage pit is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com