Step-by-step echelon-doped ternary positive electrode material and preparation method thereof

A technology of positive electrode materials and ternary materials, which is applied in the field of step-by-step doping of ternary positive electrode materials and its preparation, can solve problems such as inability to fully develop, and achieve excellent electrochemical performance, low production cost, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

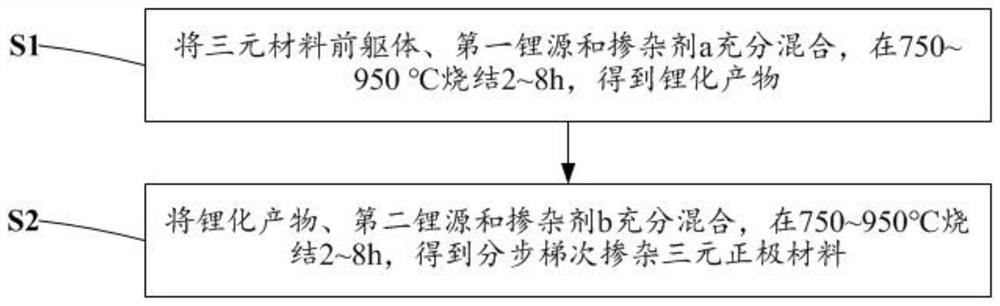

[0020] Such as figure 1 , the first aspect of the present invention provides a method for preparing a step-by-step doped ternary positive electrode material, comprising the following steps:

[0021] S1: Thoroughly mix the precursor of the ternary material, the first lithium source and the dopant a, and sinter at 750-950° C. for 2-8 hours to obtain a lithiated product. In this embodiment, the selected ternary material precursor is Ni x co y mn 1-x-y (OH) 2 , where x≥1 / 2, y≥1 / 10; the molar ratio of the ternary material precursor to lithium in the first lithium source is 1:(0.9~1.1); the molar ratio of the ternary material precursor to the dopant a 1:(0.01~0.10) Within this ratio range, the doping effect is the best. The doping elements contained in the dopant a include one or more of Rh, Mo, and Pd. In the specific embodiment of the present invention, the dopant a is Rh 2 o 3 、MoO 3 or one or more of PdO, in other implementations, it can also be other dopants, which is ...

Embodiment 1

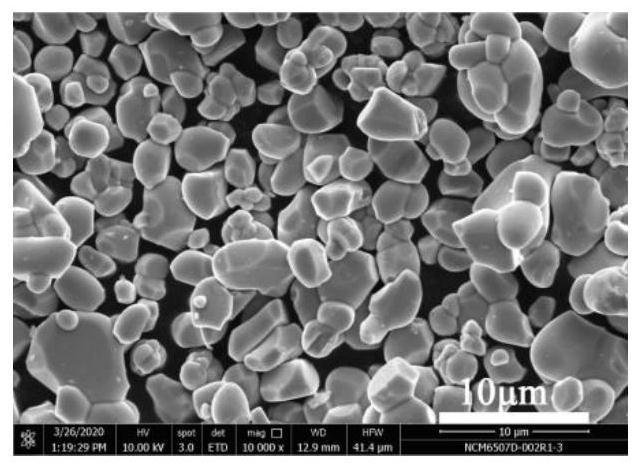

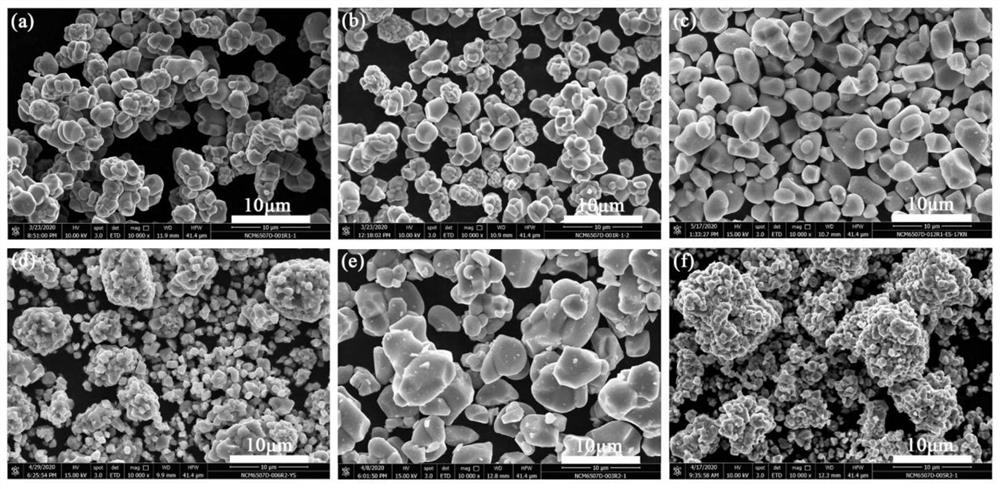

[0027] The ternary material precursor Ni 0.6 co 0.2 mn 0.2 (OH) 2 10mol, Li 2 CO 3 5mol and Rh 2 o 3 0.1mol is fully mixed evenly, and sintered at 900°C for 5h to obtain the lithiated product LiNi 0.6 co 0.2 mn 0.2 Rh 0.02 o z (Z>2).

[0028] The lithiated product LiNi 0.6 co 0.2 mn 0.2 Rh 0.02 o z 10mol, Li 2 CO 3 0.5mol and 0.1mol of SrO were fully mixed, and sintered at 900°C for 5h to obtain step-by-step doped single crystal ternary cathode material LiNi 0.6 co 0.2mn 0.2 Rh 0.02 Sr 0.01 o F (F > 2).

Embodiment 2

[0030] The ternary material precursor Ni 0.6 co 0.2 mn 0.2 (OH) 2 10mol, Li 2 CO 3 5mol and 0.2mol of PdO are fully mixed and evenly sintered at 900°C for 5h to obtain the lithiated product LiNi 0.6 co 0.2 mn 0.2 PD 0.02 o z (Z>2).

[0031] The lithiated product LiNi 0.6 co 0.2 mn 0.2 PD 0.02 o z (Z>2)10mol, Li 2 CO 3 0.5mol and La 2 o 3 0.1mol is fully mixed, and sintered at 900°C for 5h to obtain a step-by-step doped single crystal ternary cathode material LiNi 0.6 co 0.2 mn 0.2 PD 0.02 La 0.02 o F (F > 2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com