Instant ginger tea and preparation method thereof

A technology for instant ginger tea and a production method, which is applied in the directions of pharmaceutical formulations, pre-extraction tea treatment, and medical preparations containing active ingredients, etc., can solve the problems of inconvenient consumption, single formula, excessive bacteria on the surface of ginger, etc., and achieves portability. , the effect of convenient consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The raw materials include by weight: 9 parts of instant black tea powder, 18 parts of instant ginger powder, 18 parts of brown sugar, 28 parts of white sugar, 27.5 parts of edible glucose, 0.3 part of silicon dioxide, 2 parts of raspberry, 5 parts of wolfberry and dried yam 3 servings of slices.

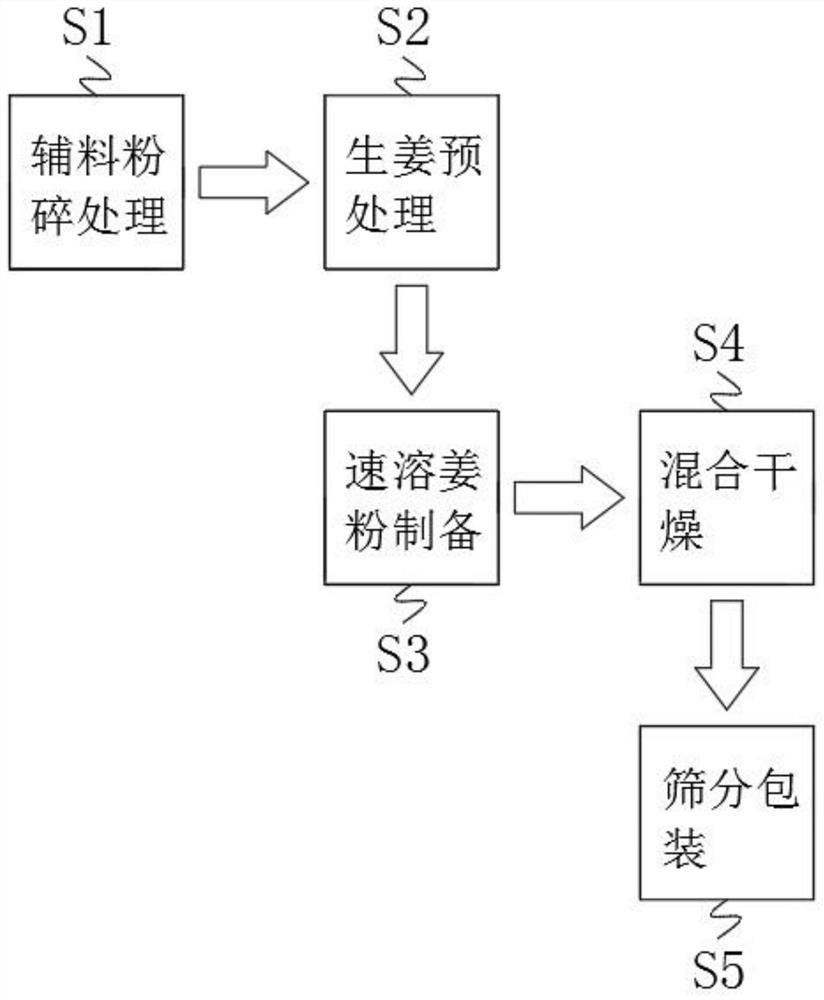

[0027] The invention also discloses a preparation method of instant ginger tea, which specifically comprises the following steps:

[0028] S1. Crushing treatment of auxiliary materials: select fresh tea leaves according to tea picking standards, and process them into finished tea by processes such as greening, kneading, and drying, and use a mechanical impact crusher to grind the finished tea, silicon dioxide, white sugar, edible glucose, silicon dioxide, Raspberry, Chinese wolfberry and dried yam tablets are preliminarily pulverized, and then further pulverized by a jet mill to obtain mixed auxiliary material powder;

[0029] S2. Ginger pretreatment: Clean the fresh ginger t...

Embodiment 2

[0037] The raw materials include by weight: 10 parts of instant black tea powder, 20 parts of instant ginger powder, 20 parts of brown sugar, 30 parts of white sugar, 29.5 parts of edible glucose, 0.4 part of silicon dioxide, 2.5 parts of raspberry, 6 parts of wolfberry and dried yam 4 servings of slices.

[0038] The invention also discloses a preparation method of instant ginger tea, which specifically comprises the following steps:

[0039] S1. Crushing treatment of auxiliary materials: select fresh tea leaves according to tea picking standards, and process them into finished tea by processes such as greening, kneading, and drying, and use a mechanical impact crusher to grind the finished tea, silicon dioxide, white sugar, edible glucose, silicon dioxide, Raspberry, Chinese wolfberry and dried yam tablets are preliminarily pulverized, and then further pulverized by a jet mill to obtain mixed auxiliary material powder;

[0040]S2. Ginger pretreatment: Clean the fresh ginger...

Embodiment 3

[0048] The raw materials include by weight: 11 parts of instant black tea powder, 22 parts of instant ginger powder, 22 parts of brown sugar, 32 parts of white sugar, 31.5 parts of edible glucose, 0.5 part of silicon dioxide, 3 parts of raspberry, 7 parts of wolfberry and dried yam 5 servings of slices.

[0049] The invention also discloses a preparation method of instant ginger tea, which specifically comprises the following steps:

[0050] S1. Crushing treatment of auxiliary materials: select fresh tea leaves according to tea picking standards, and process them into finished tea by processes such as greening, kneading, and drying, and use a mechanical impact crusher to grind the finished tea, silicon dioxide, white sugar, edible glucose, silicon dioxide, Raspberry, Chinese wolfberry and dried yam tablets are preliminarily pulverized, and then further pulverized by a jet mill to obtain mixed auxiliary material powder;

[0051] S2. Ginger pretreatment: Clean the fresh ginger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com