A kind of heat-resistant acrylate adhesive and its preparation method

A technology of acrylate and butyl acrylate, applied in adhesives, polyurea/polyurethane adhesives, adhesive types, etc., can solve problems such as high temperature resistance requirements, easy softening of the adhesive layer, and failure to peel off normally, achieving Excellent temperature resistance and good chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

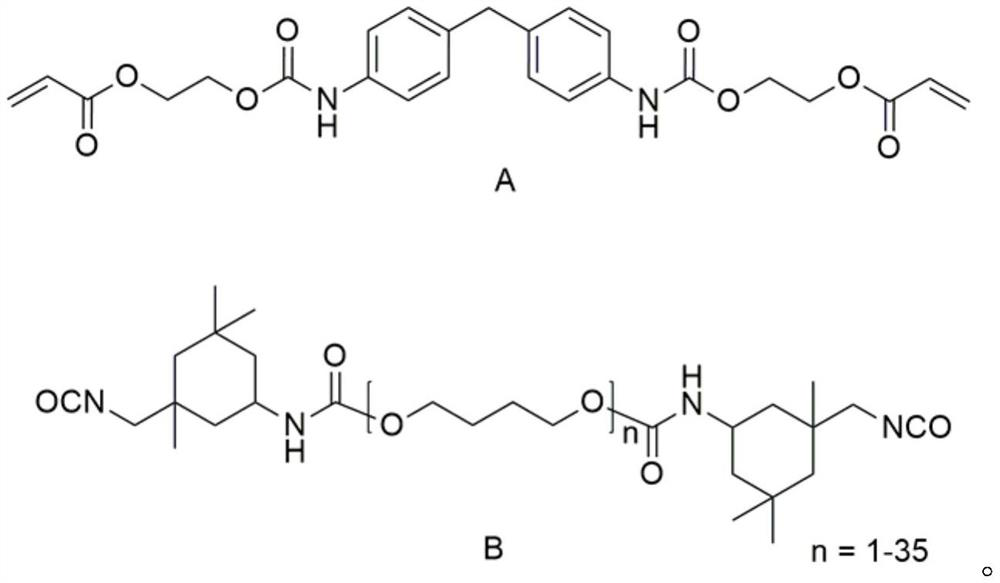

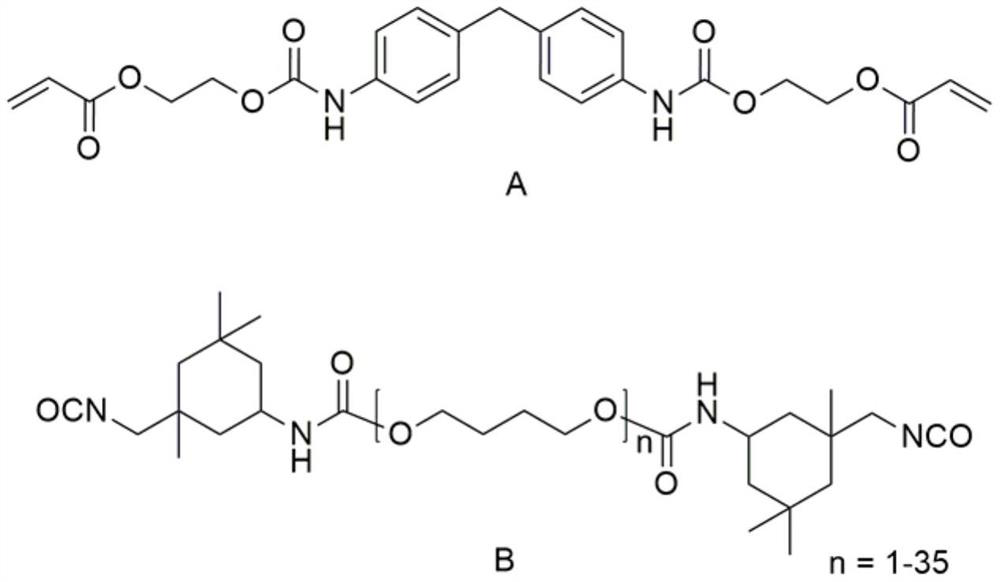

Method used

Image

Examples

Embodiment 1

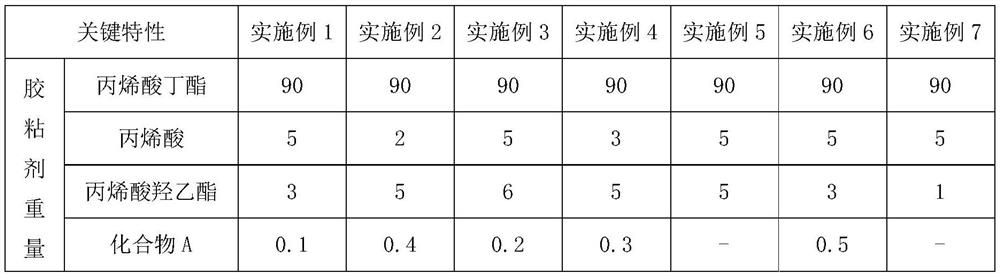

[0025] An acrylate adhesive, comprising the following raw materials by weight: 90 parts of butyl acrylate, 5 parts of acrylic acid, 3 parts of hydroxyethyl acrylate, 0.1 part of compound A, 0.1 part of compound B, 0.2 part of azobisisobutyronitrile, 120 parts of butyl acetate. wherein the value of n in compound B is 1.

[0026] The preparation method of the acrylate adhesive is as follows: weighing the above-mentioned raw materials in proportion by weight, then adding butyl acrylate, acrylic acid, hydroxyethyl acrylate, azobisisobutyronitrile, and butyl acetate into the reaction kettle in turn, and reacting Inert gas nitrogen was introduced into the system; mechanical stirring was turned on, and after reacting at 25°C for 30 min, compound A was slowly added for 1 hour, and the reaction was continued for 12 hours after the addition. Subsequently, compound B was added, and the reaction was continued for 12 hours under the condition of 90° C. to complete the reaction, and the fi...

Embodiment 2

[0028] An acrylate adhesive, comprising the following raw materials by weight: 90 parts of butyl acrylate, 2 parts of acrylic acid, 5 parts of hydroxyethyl acrylate, 0.4 parts of compound A, 0.4 part of compound B, 0.2 part of azobisisobutyronitrile, 120 parts of butyl acetate. The n value of compound B is 22.

[0029] The preparation method of the acrylate adhesive is as follows: weighing the above-mentioned raw materials in proportion by weight, then adding butyl acrylate, acrylic acid, hydroxyethyl acrylate, azobisisobutyronitrile, and butyl acetate into the reaction kettle in turn, and reacting Inert gas helium was introduced into the system; mechanical stirring was turned on, and after reacting at 25°C for 30 min, compound A was slowly added for 1 hour, and the reaction was continued for 12 hours. Subsequently, compound B was added, and the reaction was continued for 12 hours under the condition of 90° C. to complete the reaction, and the finished product was discharged....

Embodiment 3

[0031] An acrylate adhesive, comprising the following raw materials by weight: 90 parts of butyl acrylate, 5 parts of acrylic acid, 5 parts of hydroxyethyl acrylate, 0.2 part of compound A, 0.2 part of compound B, 0.2 part of azobisisobutyronitrile, 120 parts of butyl acetate. wherein the n value of compound B is 9.

[0032] The preparation method of the acrylate adhesive is as follows: weighing the above-mentioned raw materials in proportion by weight, then adding butyl acrylate, acrylic acid, hydroxyethyl acrylate, azobisisobutyronitrile, and butyl acetate into the reaction kettle in turn, and reacting Inert gas helium was introduced into the system; mechanical stirring was turned on, and after reacting at 25°C for 30 min, compound A was slowly added for 1 hour, and the reaction was continued for 12 hours. Subsequently, compound B was added, and the reaction was continued for 12 hours under the condition of 90° C. to complete the reaction, and the finished product was disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com