Preparation method of aluminum fluoride for aluminum electrolytic cell

A technology of aluminum electrolytic cell and aluminum fluoride, which is applied in the field of metallurgy, can solve problems affecting lithium sinking links and waste of resources, and achieve the effects of promoting stable production, high recovery rate, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

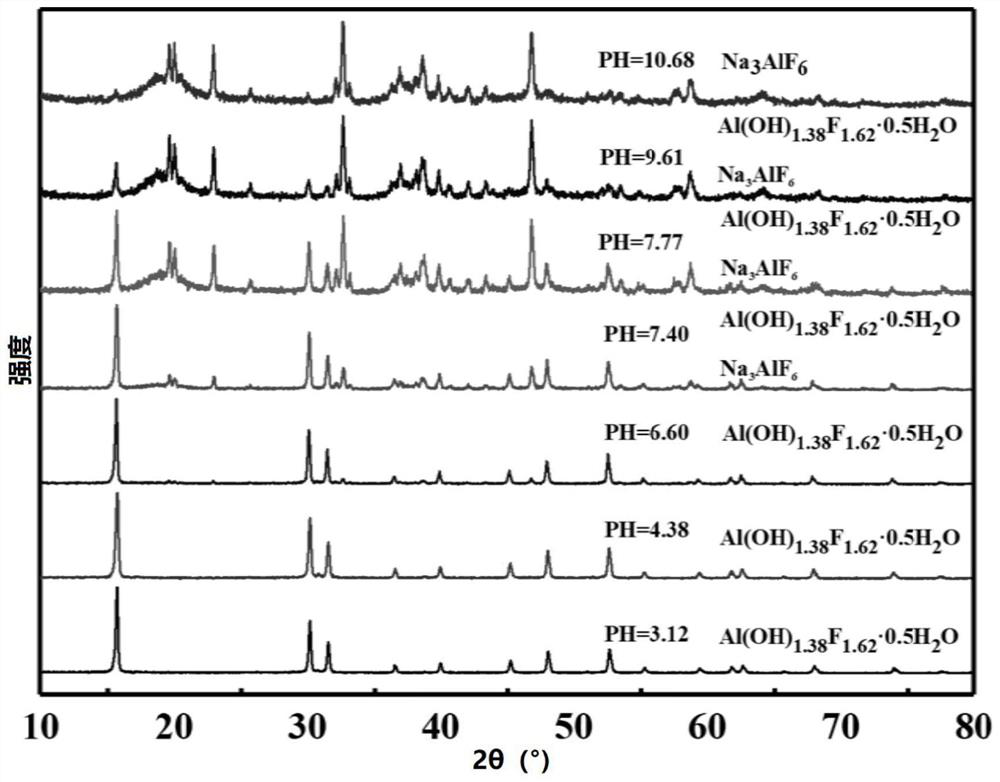

[0028] The preparation method of aluminum fluoride for aluminum electrolytic cell, the method specifically includes the following steps:

[0029] Step 1: Add 200ml of 0.5M NaOH to 1000ml of lithium-rich potassium-aluminum electrolyte leaching solution to adjust Al in the leaching solution 3+ :F - :OH - =1:1.67:1.25. The reaction was stirred at 70°C for 45 minutes, and filtered to obtain 10.53 g of aluminum hydroxyfluoride.

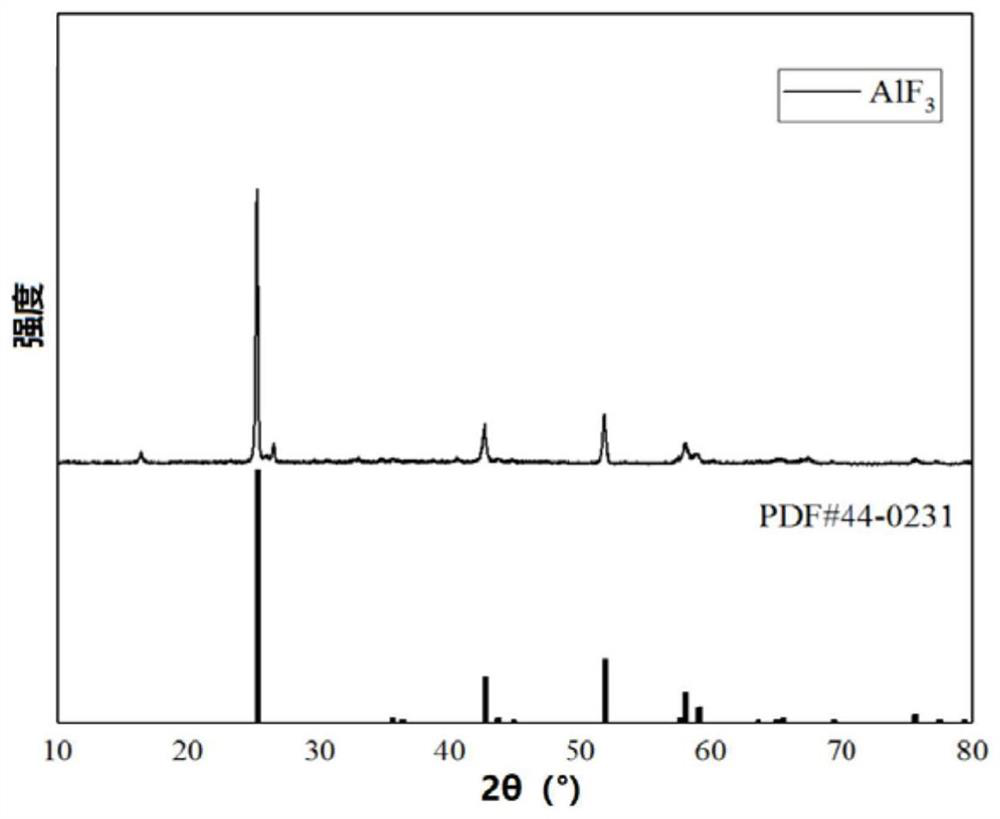

[0030] Step 2: The filtered aluminum hydroxyfluoride is calcined at 500° C. for 1 h to obtain 8.52 g of aluminum fluoride.

Embodiment 2

[0032] The preparation method of aluminum fluoride for aluminum electrolytic cell, the method specifically includes the following steps:

[0033] Step 1: Add 300ml 0.8M KOH to 1200ml lithium-rich aluminum electrolyte leaching solution to adjust the Al in the leaching solution 3+ :F -: OH - =1:1.55:1.45. The reaction was stirred at 50°C for 60 minutes and filtered to obtain 23.15 g of aluminum hydroxyfluoride.

[0034] Step 2: The filtered aluminum hydroxyfluoride is calcined at 450° C. for 2 hours to obtain 16.73 g of aluminum fluoride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com