Chemical silver plating solution and preparation method thereof

A technology for electroless silver plating and silver salt, applied in the field of electrochemistry, can solve the problems of poor electroless plating stability, insufficient coating thickness, and substandard coating performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the electroless silver plating solution of an embodiment, comprises the steps:

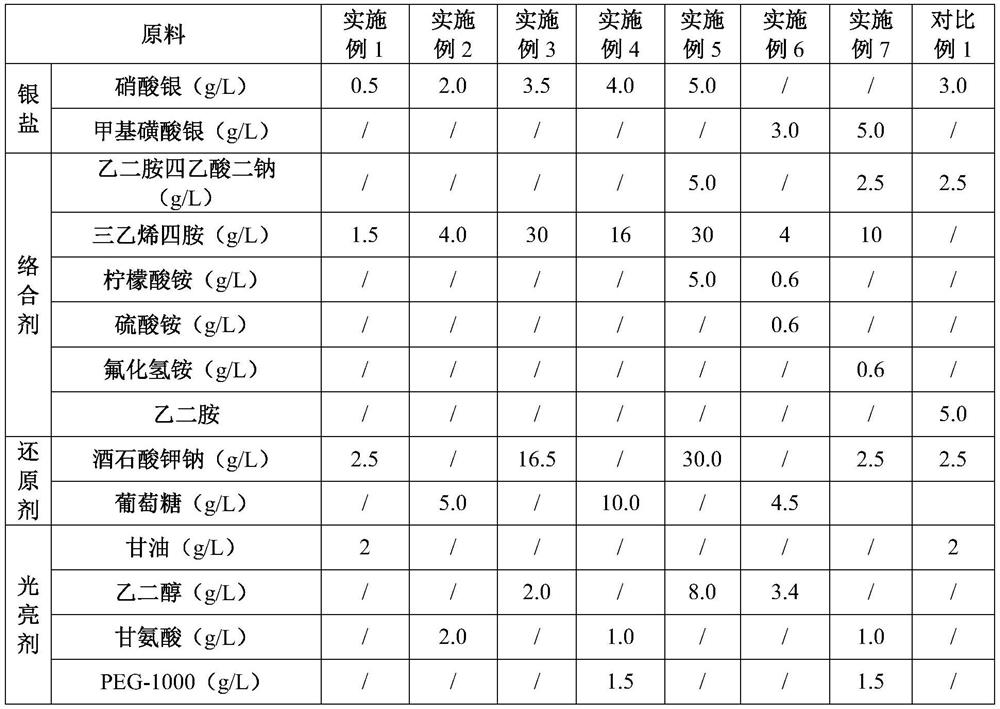

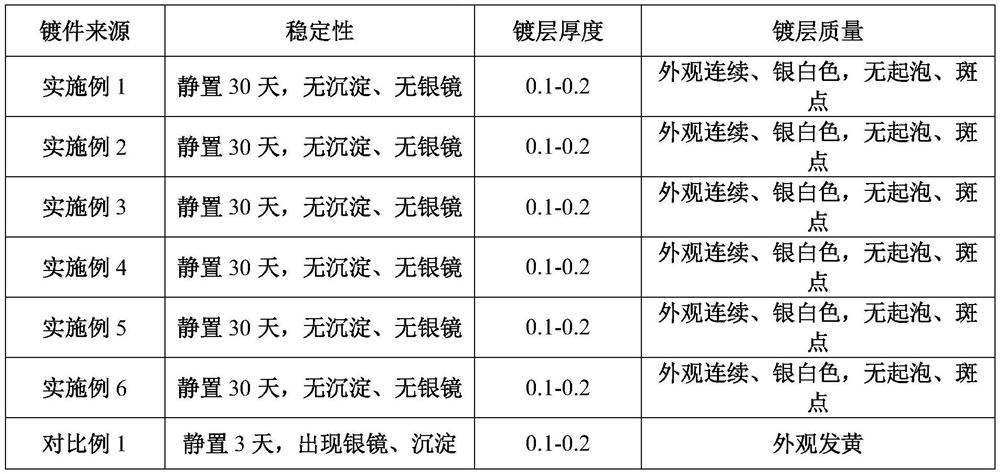

[0035] Mix raw materials including silver salt with a final concentration of 0.5g / L-5g / L, complexing agent with a final concentration of 1.5g / L-40g / L and reducing agent with a final concentration of 2.5g / L-30g / L Wherein, the above-mentioned complexing agent is selected from at least one of disodium edetate, triethylenetetramine, ammonium citrate, ammonium sulfate and ammonium bifluoride; the above-mentioned reducing agent is selected from one of sodium potassium tartrate and glucose species; the brightener is at least one selected from glycerin, ethylene glycol, glycine and polyethylene glycol with a relative molecular mass of 500-4000.

[0036] Specifically, the above-mentioned specific steps of mixing silver salt, complexing agent and reducing agent include:

[0037] dissolving the complexing agent in water to obtain a first solution;

[0038] adding an aqueous...

specific Embodiment

[0042] The following will be described in detail in conjunction with specific embodiments. The following examples do not include other components except unavoidable impurities, unless otherwise specified. The drugs and instruments used in the examples are all routine choices in the art unless otherwise specified. The experimental methods for which specific conditions are not indicated in the examples are implemented according to conventional conditions, such as conditions described in literature, books or methods recommended by the manufacturer.

[0043] Examples and comparative examples

[0044] Prepare the electroless silver plating solution:

[0045] Take deionized water as solvent preparation each embodiment and the electroless silver plating solution of comparative example, wherein each embodiment and the final concentration of the raw material of the chemical silver plating solution of comparative example and each raw material in chemical silver plating solution are as...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap