Negative ion electrostatic dust removal paper base paper and preparation method thereof

An electrostatic dust removal and negative ion technology, applied in the field of papermaking, can solve the problems of unable to remove paper particles, cloth particles and large particles of dust, unable to generate electrostatic adsorption, reduce electret static voltage, etc., and achieve lasting static voltage and adsorption , Improve the effect of electrostatic adsorption and increase the effect of charged amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

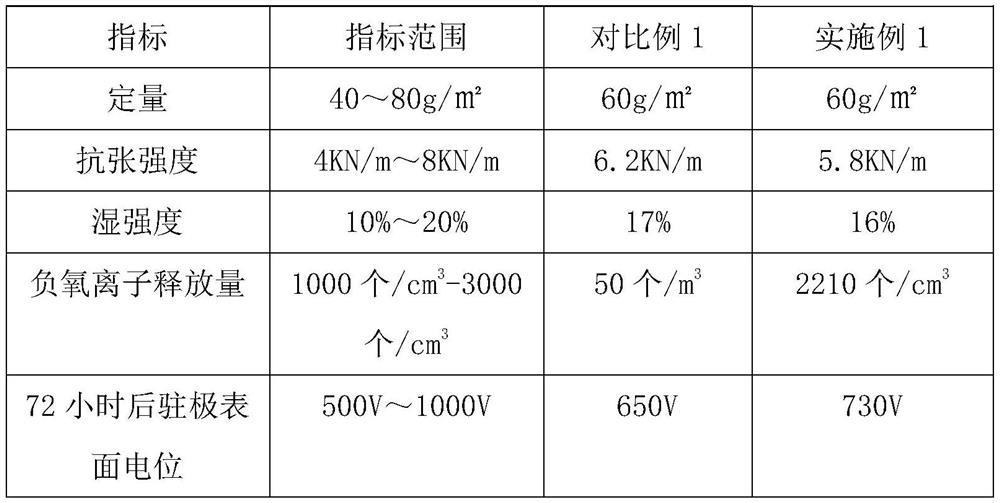

Embodiment 1

[0064] A kind of preparation method of negative ion electrostatic precipitating paper base paper, the steps are as follows:

[0065] (1) will account for the negative ion fiber of 15% of total fiber quality, account for 30% of total fiber quality electret organic fiber polypropylene fiber and account for the beating degree of total fiber quality 55% be the coniferous wood plant fiber of 30 ° of SR mix homogeneously, Add cationic polyacrylamide dry strength agent of 1% of total fiber mass and polyamide polyamine epichlorohydrin of wet strength agent of 0.5% of total fiber mass, mix and disperse evenly to prepare slurry;

[0066] (2) Dilute the slurry prepared in the step (1) to a mass concentration of 0.03% and then go online, adopt the inclined wire forming method to obtain a wet paper web, and use 40g / ㎡~80g / ㎡ kitchen wiping paper Pressing and drying conditions in production;

[0067] (3) The dried wet paper web obtained in step (2) is subjected to electrostatic electret trea...

Embodiment 2

[0072] A kind of preparation method of negative ion electrostatic precipitating paper base paper, the steps are as follows:

[0073] (1) will account for the negative ion fiber of 20% of total fiber quality, account for 30% of total fiber quality electret organic fiber polypropylene fiber and account for 50% of total fiber quality, the coniferous wood plant fiber that beating degree is 30 ° of SR is mixed evenly, Add cationic polyacrylamide dry strength agent of 1% of total fiber mass and polyamide polyamine epichlorohydrin of wet strength agent of 0.5% of total fiber mass, mix and disperse evenly to prepare slurry;

[0074] (2) Dilute the slurry prepared in the step (1) to a mass concentration of 0.03% and then go online, adopt the inclined wire forming method to obtain a wet paper web, and use 40g / ㎡~80g / ㎡ kitchen wiping paper Pressing and drying conditions in production;

[0075] (3) The dried wet paper web obtained in step (2) is subjected to electrostatic electret treatme...

Embodiment 3

[0080] A kind of preparation method of negative ion electrostatic precipitating paper base paper, the steps are as follows:

[0081] (1) will account for the negative ion fiber of 15% of total fiber quality, account for 40% of total fiber quality electret organic fiber polypropylene fiber and account for 45% of total fiber quality, beating degree is the coniferous wood plant fiber of 30 ° of SR mixing, Add cationic polyacrylamide dry strength agent of 1% of total fiber mass and polyamide polyamine epichlorohydrin of wet strength agent of 0.5% of total fiber mass, mix and disperse evenly to prepare slurry;

[0082] (2) Dilute the slurry prepared in the step (1) to a mass concentration of 0.03% and then go online, adopt the inclined wire forming method to obtain a wet paper web, and use 40g / ㎡~80g / ㎡ kitchen wiping paper Pressing and drying conditions in production;

[0083] (3) The dried wet paper web obtained in step (2) is subjected to electrostatic electret treatment, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com