A method for co-processing organic hazardous waste in cement kilns

A co-processing, cement kiln technology, applied in organic chemistry, cement production, combustion methods, etc., can solve problems such as insufficient processing capacity, too many organic components, and inability to process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

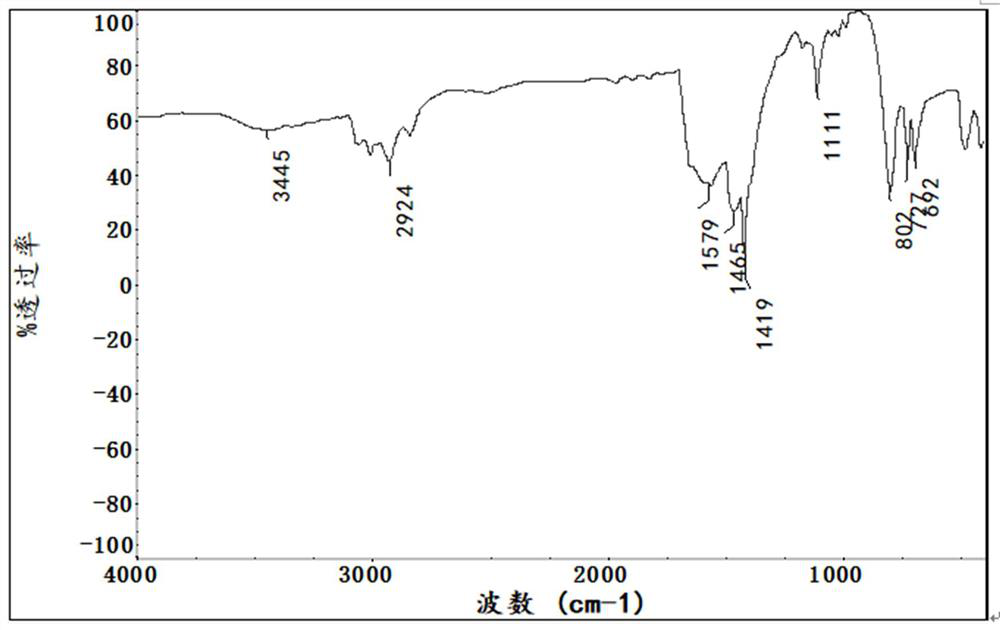

Image

Examples

Embodiment 1

[0028] A method for co-processing organic hazardous waste in a cement kiln, the main scheme of which is:

[0029] 1. Organic hazardous waste pretreatment. Firstly, the organic hazardous waste is preliminarily dewatered, and then filtered out to separate the liquid organic hazardous waste from the solid organic hazardous waste. The liquid organic hazardous waste enters the liquid organic hazardous waste storage tank; the solid organic hazardous waste The waste enters the mixer, and is mixed with the auxiliary fuel according to the addition amount of 25% according to the mass percentage content;

[0030] 2. Incineration of organic hazardous waste. The uniformly mixed solid organic hazardous waste is sent to the solid organic hazardous waste disposal furnace through the conveying equipment for incineration at a temperature of 1000 ° C. The separated liquid organic hazardous waste is added to the mass percentage content 0.5% stabilizer, stirred and mixed evenly, filtered, and the ...

Embodiment 2

[0041] A method for co-processing organic hazardous waste in a cement kiln, the main scheme of which is:

[0042] 1. Organic hazardous waste pretreatment. Firstly, the organic hazardous waste is preliminarily dewatered, and then filtered out to separate the liquid organic hazardous waste from the solid organic hazardous waste. The liquid organic hazardous waste enters the liquid organic hazardous waste storage tank; the solid organic hazardous waste The waste enters the mixer and is mixed with the auxiliary fuel according to the mass percentage content and the addition amount of 30%;

[0043] 2. Incineration of organic hazardous waste. The uniformly mixed solid organic hazardous waste is sent to the solid organic hazardous waste disposal furnace through the conveying equipment for incineration at a temperature of 1100 ° C. The separated liquid organic hazardous waste is added to the mass percentage content 1.6% stabilizer, stir and mix evenly and then filter, and the obtained ...

Embodiment 3

[0054] A method for co-processing organic hazardous waste in a cement kiln, the main scheme of which is:

[0055] 1. Organic hazardous waste pretreatment. Firstly, the organic hazardous waste is preliminarily dewatered, and then filtered out to separate the liquid organic hazardous waste from the solid organic hazardous waste. The liquid organic hazardous waste enters the liquid organic hazardous waste storage tank; the solid organic hazardous waste The waste enters the mixer, and is mixed with the auxiliary fuel according to the addition amount of 35% according to the mass percentage content;

[0056] 2. Incineration of organic hazardous waste. The uniformly mixed solid organic hazardous waste is sent to the solid organic hazardous waste disposal furnace through the conveying equipment for incineration at a temperature of 1200 ° C. The separated liquid organic hazardous waste is added to the mass percentage content 2.3% stabilizer, stirred and mixed evenly, filtered, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com