Quartz reaction kettle device for in-situ online monitoring of low-temperature high-pressure reaction

A reaction in situ, low temperature and high pressure technology, applied in sampling devices, preparation of test samples, Raman scattering, etc., can solve the problem of online observation and analysis of intermediate products that cannot change in phase state, invisible reaction process, and large consumption of raw materials, etc. problem, to achieve the effect of simple structure, avoiding catalytic effect, and small consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

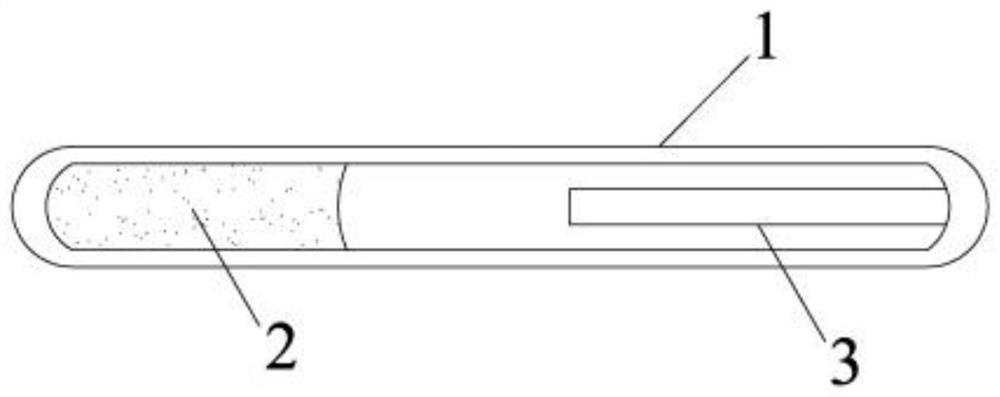

[0042] In Example 1, the main body of the quartz reactor was used to study the reaction of ozone and chlorobenzene under low temperature and high pressure conditions.

[0043] Such as figure 1 As shown, the main body of a quartz reactor is circular, with an outer diameter of 4.0 mm, an inner diameter of 2.0 mm, and a length of 50 mm. The added reaction substances are chlorobenzene and ozone.

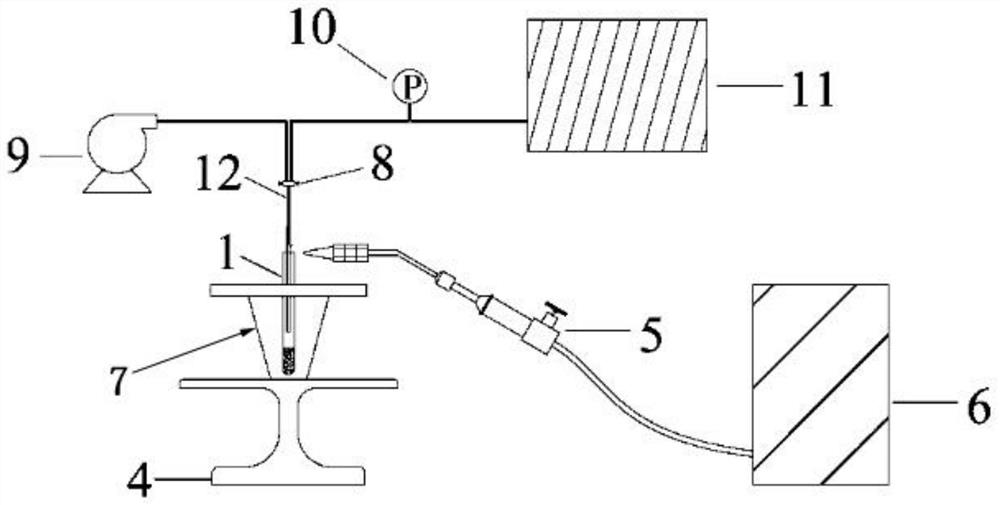

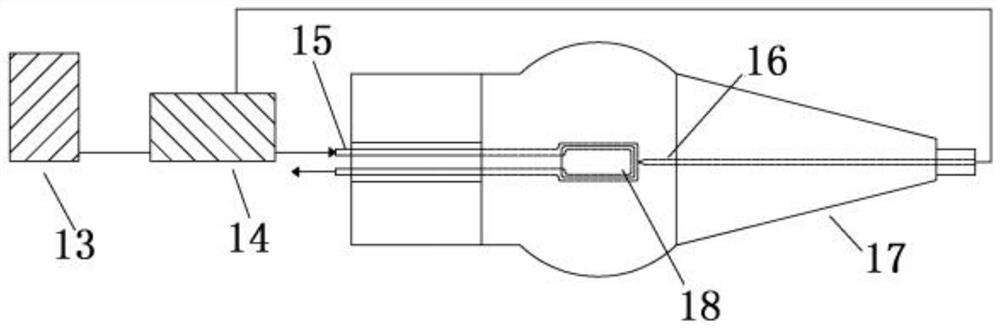

[0044] Such as figure 2 Shown, a kind of manufacturing equipment of quartz reactor. First, use a grinding wheel to cut a quartz tube about 50 mm long (2mmID, 4mmOD), turn on the high-purity hydrogen generator, and after electrolyzing enough hydrogen-oxygen mixed gas, turn on the welding torch and ignite it, and seal one end of the quartz tube with a hydrogen-oxygen flame. The welding sealing effect is ready for use after passing the test. Use a micro-sampling needle, put a certain amount of chlorobenzene into the quartz tube according to the experimental design, and centrifuge at a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com