Rice flour making method for improving tasty effect of rice flour

A production method and technology of rice noodles, applied in the direction of food science, etc., can solve the problem that the effect of taste performance is not optimal, and achieve the effect of improving taste performance, oil absorption rate, and easy gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

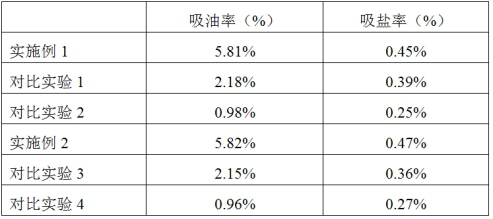

Examples

Embodiment 1

[0017] Embodiment 1: a kind of rice flour production method that improves rice flour appetizing effect, comprises the following steps:

[0018] (1) Put Zhengui rice grains in a high-speed pulverizer, pulverize them at a speed of 2500r / min, and pass through a 60-mesh sieve to obtain rice flour. Weigh 100g of rice flour and put it in a container, add 125mL of distilled water and stir evenly. Add 0.5g of Saccharomyces cerevisiae, add 0.1% of the mass of rice flour a-amylase, use a homogenizer to homogenize for 20s, adjust the incubator to 28°C, put the rice flour in the incubator and ferment for 1.5h at a constant temperature to obtain rice pulp.

[0019] (2) Add 0.8% of the mass of rice flour to the rice milk with alkaline protease and mix well, then enzymatically hydrolyze at 45°C for 2 hours.

[0020] (3) Add 0.5% oleic acid to the enzymolyzed rice milk for 8 minutes, then add 40g of potato starch and 0.5g of compound phosphate for 2 minutes.

[0021] (4) After washing with ...

Embodiment 2

[0025] (1) Put Zhengui rice grains in a high-speed pulverizer, pulverize them at a speed of 2500r / min, and pass through a 60-mesh sieve to obtain rice flour. Weigh 100g of rice flour and put it in a container, add 125mL of distilled water and stir evenly. Add 0.5g of Saccharomyces cerevisiae, add 0.1% of the mass of rice flour a-amylase, use a homogenizer to homogenize for 20s, adjust the incubator to 28°C, put the rice flour in the incubator and ferment for 1.5h at a constant temperature to obtain rice pulp.

[0026] (2) Add alkaline protease of 0.8% by mass of rice flour to the rice milk, mix well, and enzymatically hydrolyze at 42°C for 2 hours.

[0027] (3) Add 0.55% oleic acid to the enzymatic hydrolyzed rice milk for 8 minutes, then add 40g of potato starch and 0.5g of compound phosphate for 2 minutes.

[0028] (4) After washing with water, remove the water, put the rice milk in a cooking pot and cook for 5 minutes to make it into a paste.

[0029] (5) Knead the cooked...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com