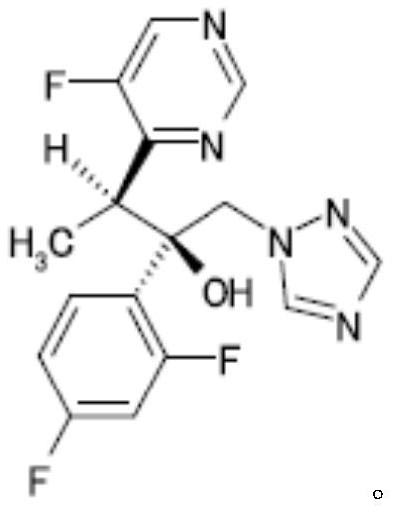

Preparation method of voriconazole for injection

A technology for voriconazole and injection, which is applied in the field of preparation of voriconazole for injection, which can solve the problems of uneven finished product, long freeze-drying cycle, rough powder cake, etc., and achieve the effects of improving clarity, improving crystal form, and promoting uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

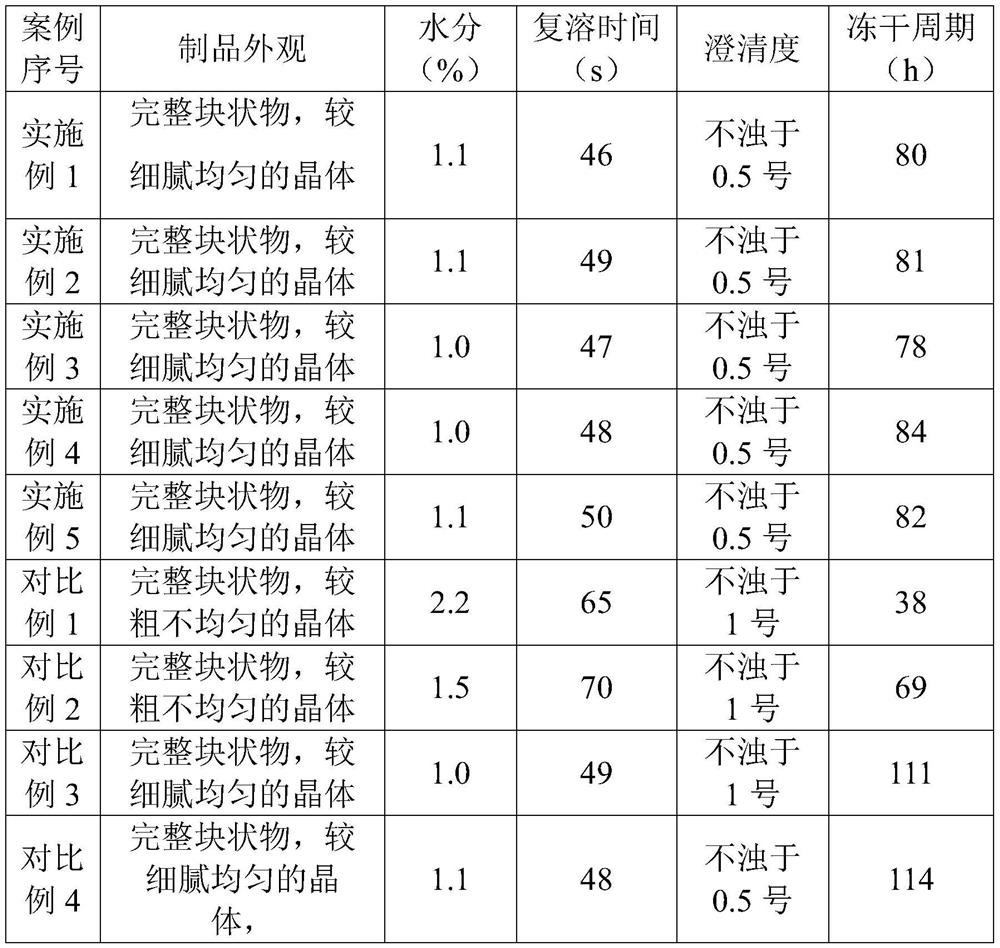

Examples

Embodiment 1

[0019] 1) Preparation: Weigh voriconazole and sulfobutylbetacyclodextrin (SBECD) at a weight ratio of 1:18, add SBECD to an appropriate amount of water, add voriconazole after SBECD is completely dissolved, and continue stirring until completely dissolved and mixed evenly. Obtain a sample containing voriconazole;

[0020] 2) Sterile filtration, half-stoppering for filling: filter the sample to the aseptic filling room with 0.45 μm and 0.22 μm sterile filters, fill in 25ml vials, and half-stopper;

[0021] 3) vacuum freeze drying:

[0022] a. Overcooling: place the subpackaged samples on the partition of the freeze dryer, set the temperature of the partition to 0°C, and keep at this temperature for 4 hours;

[0023] b. Pre-freezing: set the partition temperature to -45°C and keep at this temperature for 3 hours;

[0024] c. Annealing treatment: Raise the temperature of the separator to -10°C, keep it at this temperature for 5h, and then lower it to -45°C and keep it for 4h; ...

Embodiment 2

[0030] 1) Preparation: Weigh voriconazole and SBECD according to a weight ratio of 1:15, add SBECD into water, add voriconazole after SBECD is completely dissolved, and continue stirring until completely dissolved and mixed uniformly to obtain a voriconazole-containing sample;

[0031] 2) Sterile filtration, half-stoppering for filling: filter the sample to the aseptic filling room with 0.45 μm and 0.22 μm sterile filters, fill in 25ml vials, and half-stopper;

[0032] 3) vacuum freeze drying:

[0033] a. Overcooling: place the subpackaged samples on the partition of the freeze dryer, set the temperature of the partition to -5°C, and keep at this temperature for 2 hours;

[0034] b. Pre-freezing: set the partition temperature to -42°C and keep at this temperature for 4 hours;

[0035] c. Annealing treatment: Raise the temperature of the separator to -5°C, keep it at this temperature for 3 hours, and then lower it to -40°C and keep it for 6 hours;

[0036] d. Vacuuming: Turn ...

Embodiment 3

[0041] 1) Preparation: Weigh voriconazole and SBECD according to a weight ratio of 1:16, add SBECD to an appropriate amount of water, add voriconazole after SBECD is completely dissolved, and continue stirring until completely dissolved and mixed evenly to obtain a voriconazole-containing sample;

[0042] 2) Sterile filtration, half-stoppering for filling: filter the sample to the aseptic filling room with 0.45 μm and 0.22 μm sterile filters, fill in 25ml vials, and half-stopper;

[0043] 3) vacuum freeze drying:

[0044] a. Overcooling: place the subpackaged samples on the partition of the freeze dryer, set the temperature of the partition to -4°C, and keep at this temperature for 3 hours;

[0045] b. Pre-freezing: set the partition temperature to -40°C, and keep at this temperature for 6 hours;

[0046] c. Annealing treatment: Raise the temperature of the separator to -8°C, keep it at this temperature for 4 hours, and then lower it to -43°C and keep it for 5 hours;

[0047...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com