Synthetic method of tungsten trioxide/ZIF-8 composite catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A kind of synthetic method of tungsten trioxide / ZIF-8 composite catalyst, comprises the following steps at least:

[0027] (1) Disperse tungsten trioxide nanosheets in deionized water, add 2-methylimidazole aqueous solution and sonicate for 5-15min;

[0028] (2) Add 2-methylimidazole aqueous solution drop by drop, and stir for 8-15min;

[0029] (3) Add the zinc acetate aqueous solution prepared now, and stir at room temperature for 1.5-2.5 hours;

[0030] (4) Washing with washing solution and drying to obtain the target product.

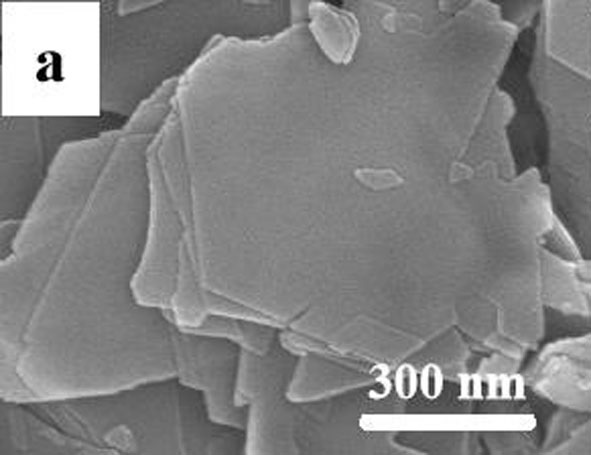

[0031] Preferably, the preparation method of tungsten trioxide nanosheets is as follows: dissolving sodium tungstate dihydrate and polyvinylpyrrolidone in deionized water; then adding acetic acid dropwise to obtain a mixed solution, ultrasonicating the mixed solution for 30 minutes and putting it into high pressure Reaction in the kettle for 7-9h, the reaction temperature is 180-220°C, and the crude product is obtained after natural cooling ...

Embodiment 1

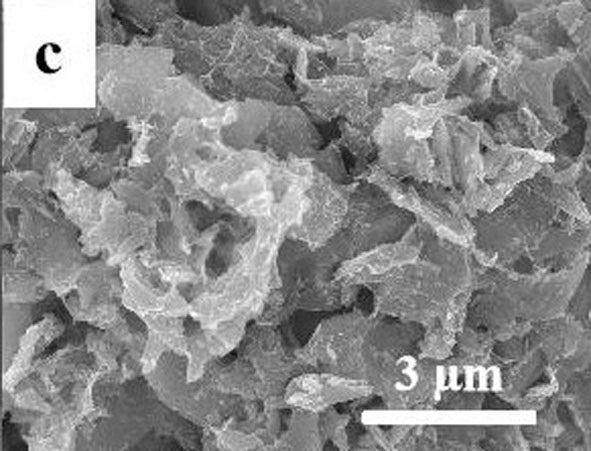

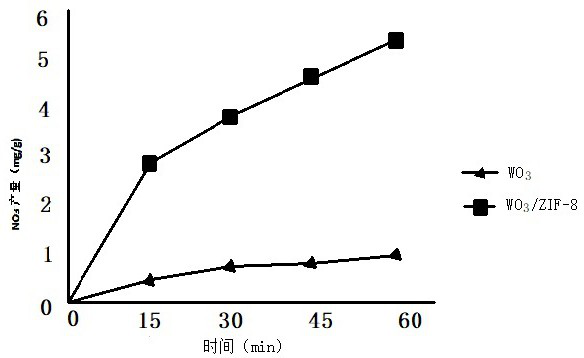

[0040] A synthesis method of tungsten trioxide / ZIF-8 composite catalyst, dissolving 660mg sodium tungstate dihydrate and 100mg polyvinylpyrrolidone (Fw=58000) in 12mL deionized water; then adding 1ml acetic acid dropwise to obtain a yellow-green mixed solution , put the mixed solution into an autoclave coated with Teflon liner to react for 7h after ultrasonication for 30 minutes. , and the powder was washed 6 times with deionized water and absolute ethanol to obtain a wet product, and the wet product was placed in a vacuum drying oven to dry to obtain tungsten trioxide nanosheets. Disperse 2.2mg of tungsten trioxide nanosheets in 8ml of deionized water, add 0.1ml of 2-methylimidazole aqueous solution (0.28mol / L) and sonicate for 5min; then add 0.9ml of 2-methylimidazole dropwise Aqueous solution (0.28mol / L), after stirring for 8-15min, add the newly prepared zinc acetate aqueous solution with a concentration of 0.1mol / L, and stir at room temperature for 1.5h; use deionized wat...

Embodiment 2

[0042] A synthesis method of tungsten trioxide / ZIF-8 composite catalyst, dissolving 660mg sodium tungstate dihydrate and 100mg polyvinylpyrrolidone (Fw=58000) in 12mL deionized water; then adding 1ml acetic acid dropwise to obtain a yellow-green mixed solution , put the mixed solution into an autoclave coated with polytetrafluoroethylene to react for 8 hours after ultrasonication for 30 minutes. , and the powder was washed 7 times with deionized water and absolute ethanol to obtain a wet product, and the wet product was placed in a vacuum drying oven to dry to obtain tungsten trioxide nanosheets. Disperse 2.2mg of tungsten trioxide nanosheets in 8ml of deionized water, and add 0.1ml of 2-methylimidazole aqueous solution (1.12mol / L) to it and sonicate for 10min; add 0.9ml of 2-methylimidazole aqueous solution drop by drop (1.12mol / L), stirred for 10min; added the newly prepared zinc acetate aqueous solution with a concentration of 0.4mol / L, stirred at room temperature for 2.5h,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com