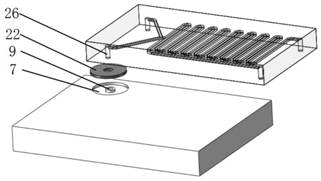

Temperature-control pressure-resistant clamp device of high-flux visual micro-fluidic chip

A technology of microfluidic chip and fixture device, which is applied in the direction of supporting utensils, laboratory utensils, chemical instruments and methods, etc., which can solve the problems of poor sealing, difficult to meet, and small size of the feeding hole, and reduce the manufacturing cost. and maintenance costs, low manufacturing and maintenance costs, and strong liquid leakage prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

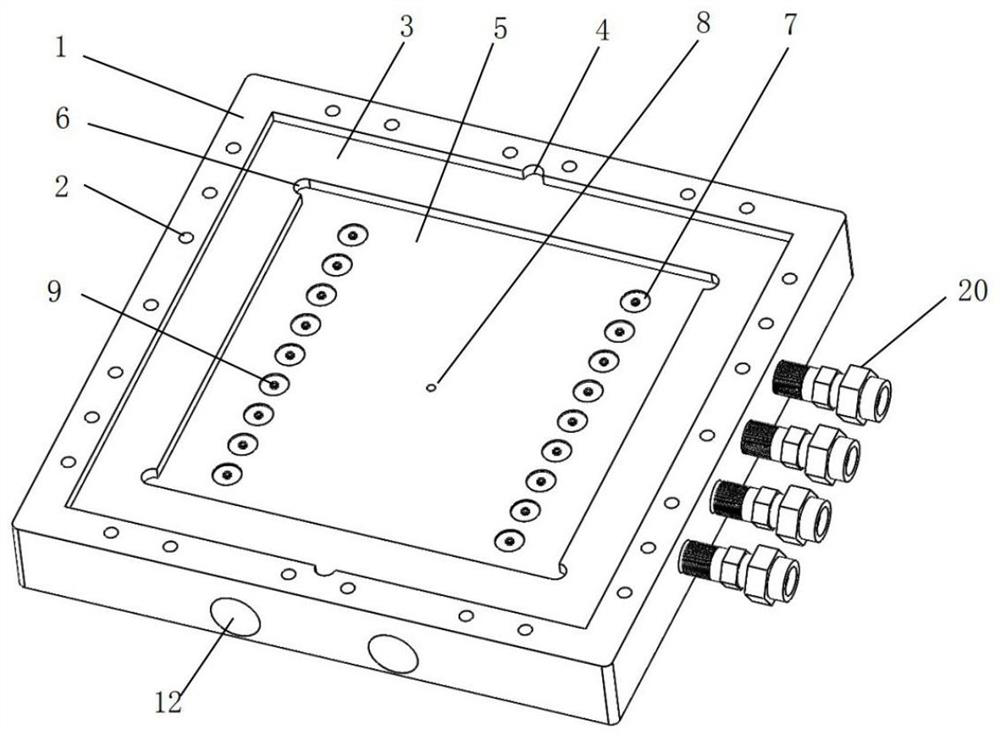

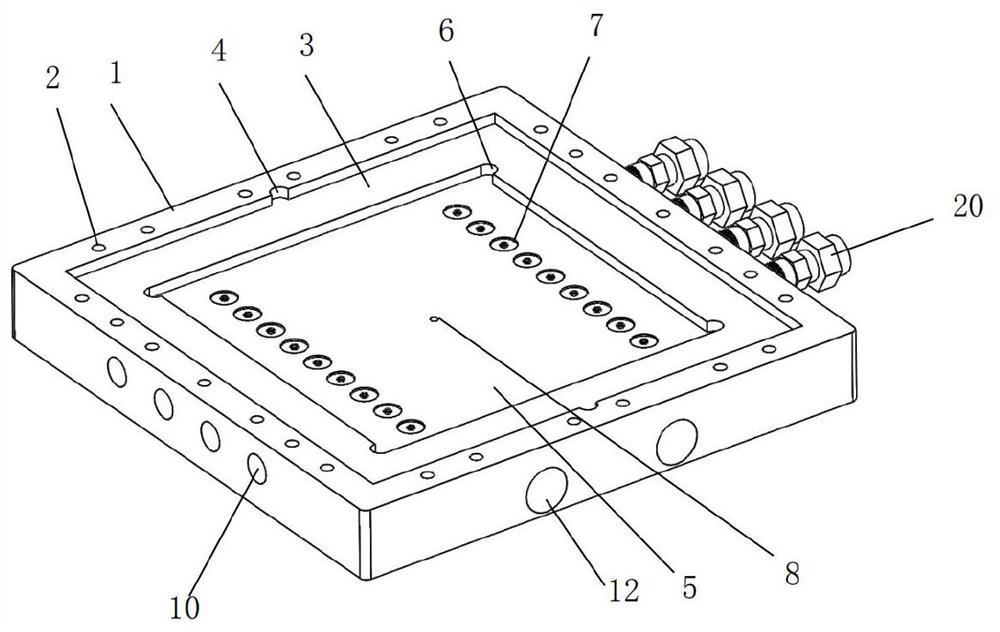

[0036] The technical solutions of the present invention will be described in detail below through embodiments with reference to the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention.

[0037] The term "and / or" in this article is just an association relationship describing associated objects, which means that there may be three relationships, for example, A and / or B, which can mean: A exists alone, B exists alone, and A and B exist simultaneously. In the three cases of B, the term " / and" in this article is to describe another associated object relationship, which means that there can be two relationships, for example, A / and B, which can mean: there is A alone, and there are two cases of A and B alone , In addition, the character " / " in this article generally indicates that the contextual objects are an "or" relationship.

[0038] accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com