Porous microsphere particle for three-dimensional cell culture and preparation method thereof

A technology of porous microspheres and granules, applied in general culture methods, cell culture supports/coatings, biochemical equipment and methods, etc., can solve problems such as high cost, high energy consumption, and uneven feed ratio, and achieve operational Convenience and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Prepare porous chitosan / gelatin microsphere particles for three-dimensional cell culture as follows:

[0056] (1) Select chitosan and gelatin (the ratio of chitosan and gelatin is 1:2) as the carrier material, dissolve in 2v / v% acetic acid solution, stir magnetically at 50°C until completely dissolved, the stirring speed is 600rpm, Afterwards, a chitosan / gelatin solution with a solid content of 3 wt % was obtained by homogenizing for 60 min under a pressure of 600 bar through a high-pressure homogenizer.

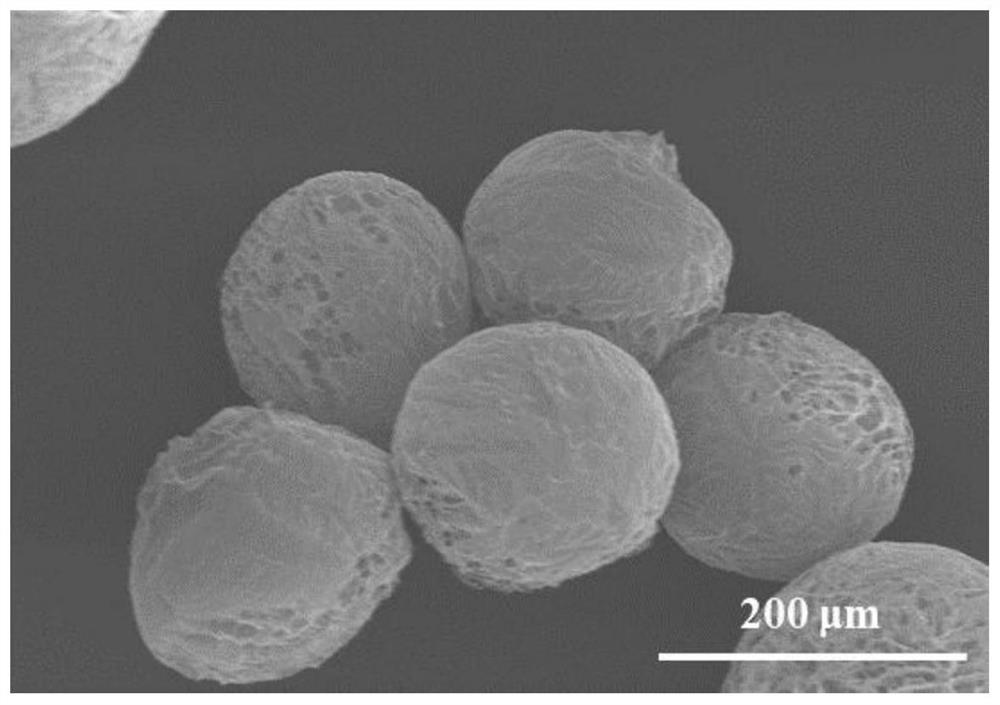

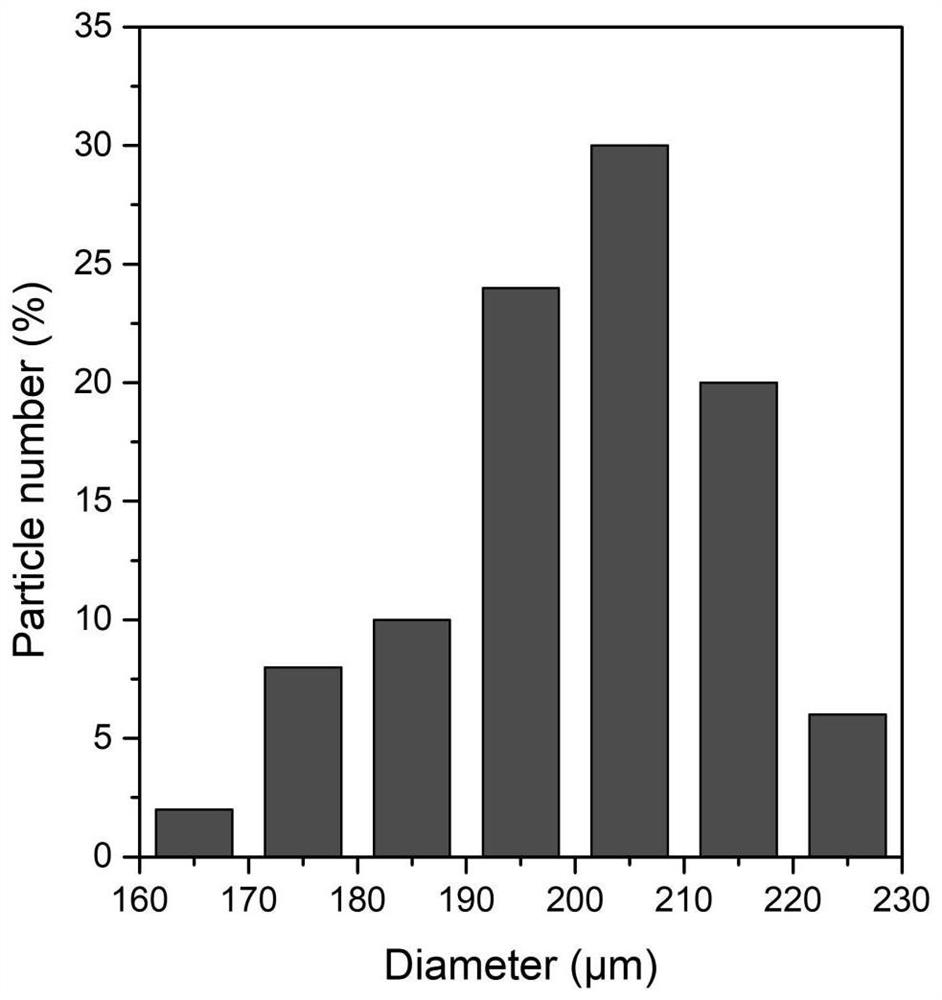

[0057] (2) Pour the chitosan / gelatin precursor solution configured in step (1) into the liquid storage tank, connect the microfluidic atomizer through a catheter, and atomize the precursor solution into small uniform droplets, the droplet size Controlled at about 200μm, the atomization pressure is 1.5kg / cm 3 , the working vibration frequency of the atomizer is 12kHz, and the amplitude is 15Vpp.

[0058] (3) The droplets in step (2) are spray-freezed to obtain ice ba...

Embodiment 2

[0061] (1) Gelatin is selected as the carrier material, dissolved in pure water with a solid content of 5wt%, magnetically stirred at 50°C until completely dissolved, and the stirring speed is 600rpm, and a 5wt% gelatin aqueous solution is prepared.

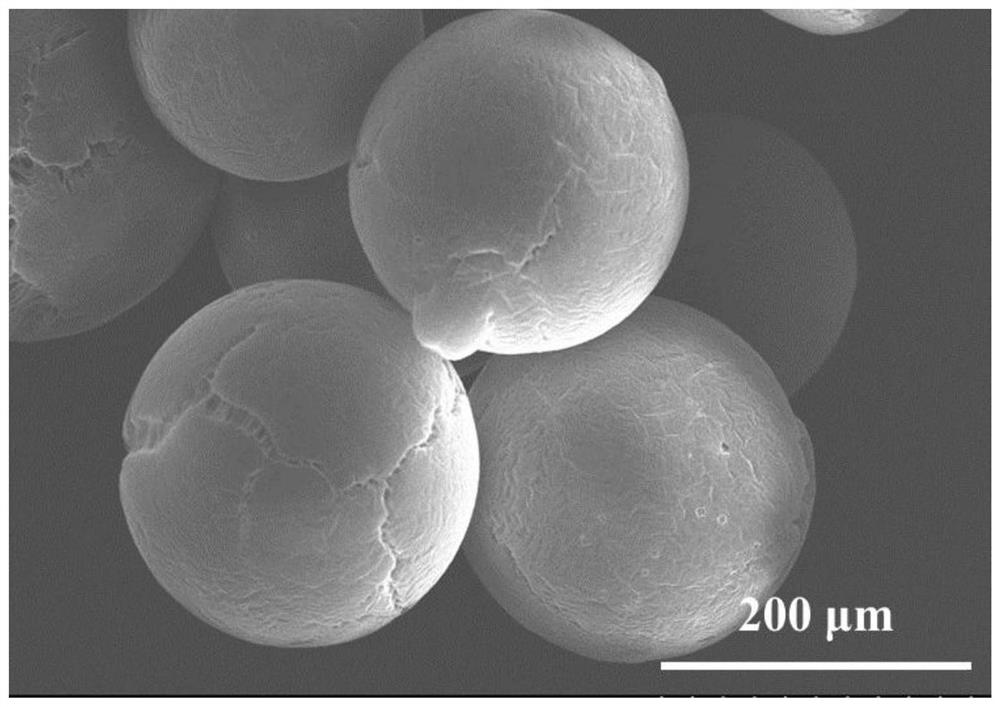

[0062] (2) Import the gelatin aqueous solution prepared in step (1) into the liquid storage tank, connect the microfluidic atomizer through the catheter, and atomize the precursor liquid into fine uniform droplets, and the droplet size is controlled at about 200 μm. The atomization pressure is 1kg / cm3, the working vibration frequency of the atomizer is 12kHz, and the amplitude is 15Vpp.

[0063] (3) The droplets in step (2) are spray-freezed to obtain ice ball particles with uniform size, the tower wall temperature is set to -80°C, and the cold air flow rate is set to 250L / min.

[0064] (4) Transfer the ice ball particles collected in step (3) to a vacuum freeze dryer, and freeze and dry them under vacuum for 72 hours to obtain g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com