Heating device

A heating device and technology to be heated, applied in electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of temperature-sensitive plastics, shortened equipment life, low service life, etc., to achieve fast heat transfer speed, improve The effect of heat transfer efficiency and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

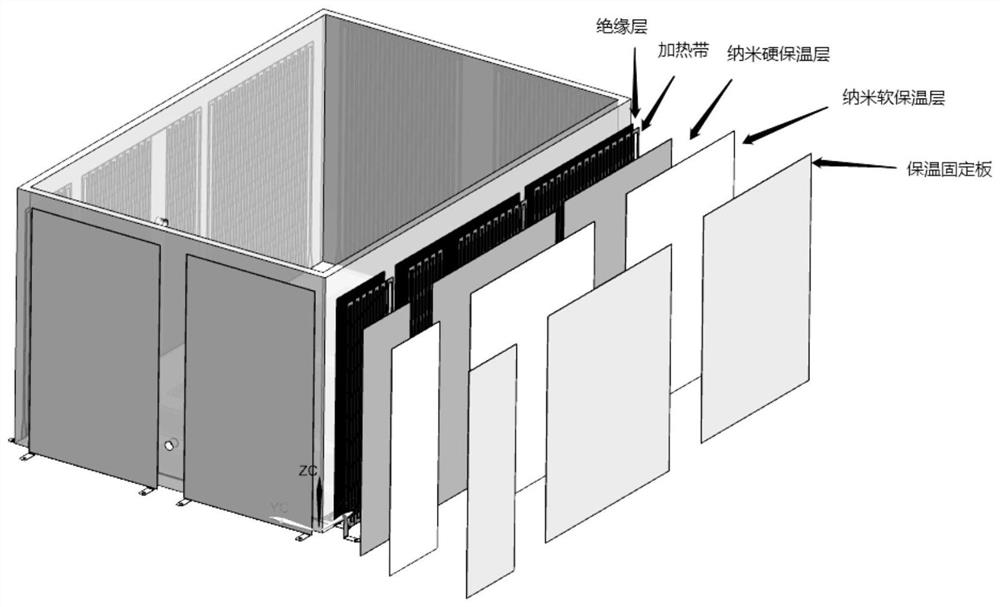

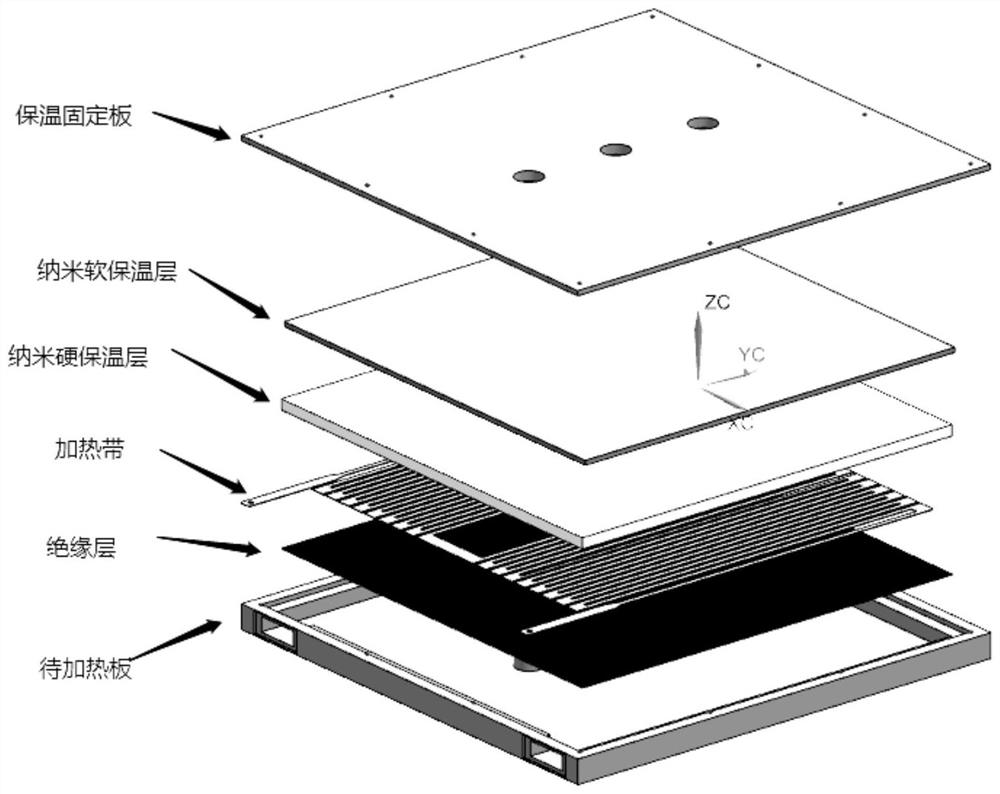

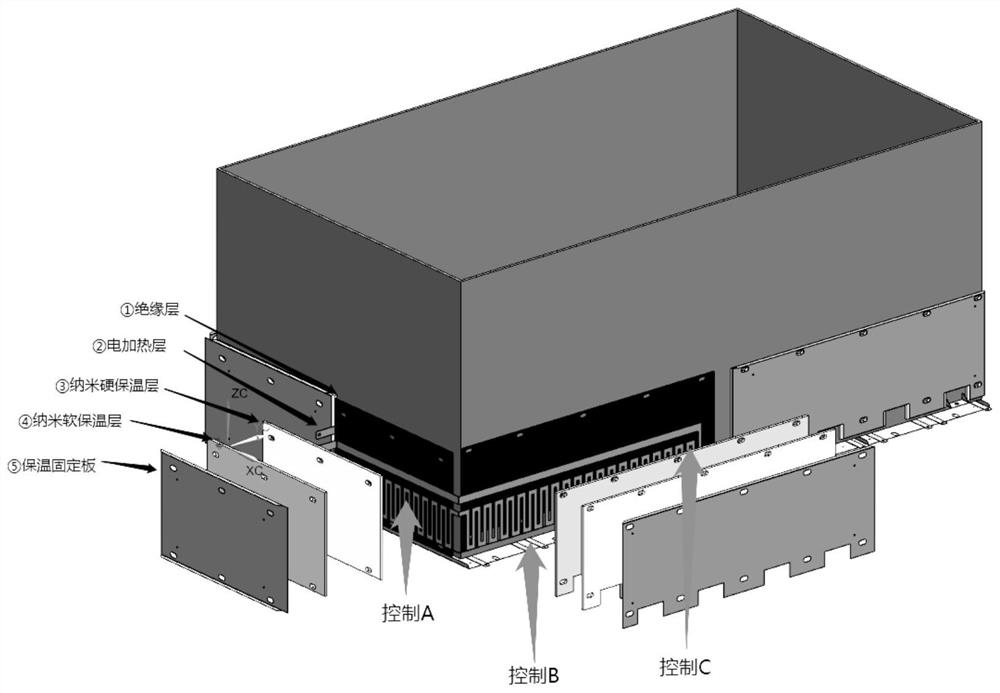

[0057] A heating device, in order to visualize the image, the structure of each layer of heating is split and displayed (for details, see Figure 2 to Figure 4 ), the heating device includes an object to be heated 200, an insulating layer 201, a heating assembly 202, a nano-hard thermal insulation layer 203, a nano-soft thermal insulation layer 204, and a thermal insulation fixing plate 205. Heating object 200, insulation layer 201, heating assembly 202, nanometer hard insulation layer 203, nanometer soft insulation layer 204, insulation fixing plate 205, insulation layer 201 is positioned on the object to be heated 200 and arranges object to be heated 200 side by side, heating assembly 202 The insulation layer 201 is arranged side by side on the insulating layer 201, the nano-hard insulation layer 203 is located on the heating assembly 202 and the heating assembly 202 is arranged side by side, and the nano-soft insulation layer 204 is located on the nano-hard insulation layer ...

Embodiment 2

[0061] A heating device, in order to visualize the image, the structure of each layer of heating is split and displayed. For details, see Figure 2 to Figure 4 . The heating device includes an object to be heated 200, an insulating layer 201, a heating assembly 202, a nano-hard insulation layer 203, a nano-soft insulation layer 204 and a fixed plate 205 for heat preservation. , insulation layer 201, heating assembly 202, nanometer hard insulation layer 203, nanometer soft insulation layer 204, insulation fixing plate 205, insulation layer 201 is positioned on the object to be heated 200 and arranges the object to be heated 200 side by side, and heating assembly 202 is positioned at insulation layer The upper 201 arranges the insulating layer 201 in parallel, the nano hard insulation layer 203 is located on the heating assembly 202 and arranges the heating assembly 202 in parallel, the nano soft insulation layer 204 is located on the nano hard insulation layer 203 and arranges ...

Embodiment 3

[0069] A heating device, in order to visualize the image, the structure of each layer of heating is split and displayed. For details, see Figure 2 to Figure 4 . The heating device includes an object to be heated 200, an insulating layer 201, a heating assembly 202, a nano-hard insulation layer 203, a nano-soft insulation layer 204 and a fixed plate 205 for heat preservation. , insulation layer 201, heating assembly 202, nanometer hard insulation layer 203, nanometer soft insulation layer 204, insulation fixing plate 205, insulation layer 201 is positioned on the object to be heated 200 and arranges the object to be heated 200 side by side, and heating assembly 202 is positioned at insulation layer The upper 201 arranges the insulating layer 201 in parallel, the nano hard insulation layer 203 is located on the heating assembly 202 and arranges the heating assembly 202 in parallel, the nano soft insulation layer 204 is located on the nano hard insulation layer 203 and arranges ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com