Low-voltage infrared electrothermal film and preparation method thereof

An electric heating film and infrared electricity technology, applied in electric heating devices, ohmic resistance heating, ohmic resistance heating parts, etc., can solve the problem that the insulation and stability of the electric heating film cannot be effectively maintained for a long time, and the preparation process of the low-voltage infrared electric heating film is complicated. , poor infrared emissivity, etc., to achieve significant infrared radiation absorption and reflection effects, reduce heat loss, and stabilize adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

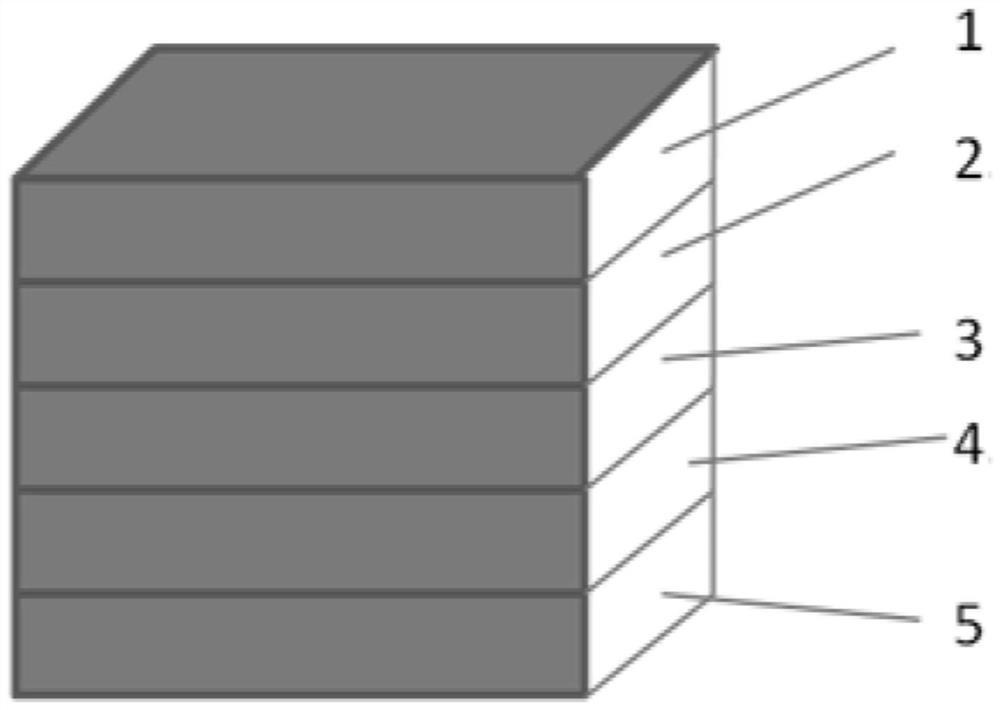

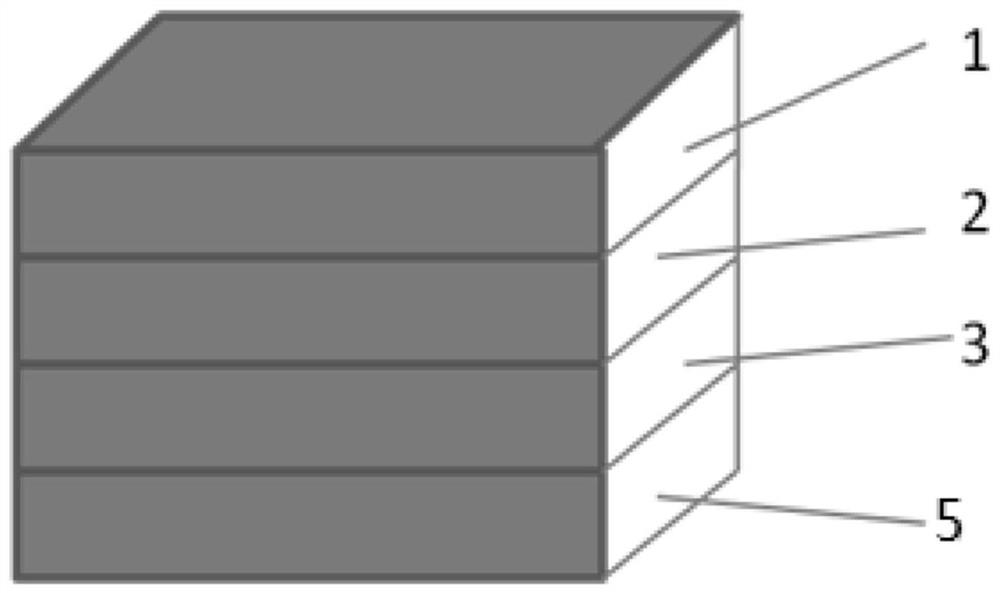

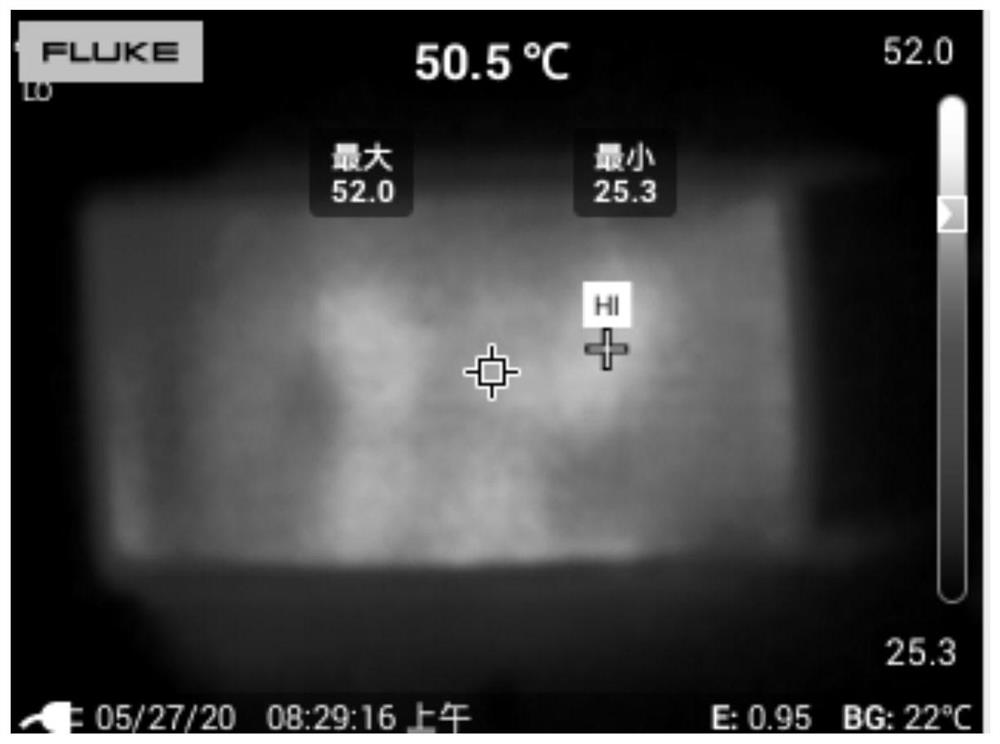

[0037] A low-voltage infrared electrothermal film, the low-voltage infrared electrothermal film includes a first insulating and water-proof layer 1, a first conductive layer 2, a radiation enhancement layer 3 and a second insulating and water-proof layer 5, and the first insulating and water-proof layer 1 , the first conductive layer 2, the radiation enhancement layer 3 and the second insulating water-proof layer 5 are connected in sequence, and the first conductive layer 2 is a conductive graphite material, and the radiation enhancement layer 3 includes nitride Titanium material or titanium carbide material.

[0038] The low-voltage infrared electric heating film also includes a second conductive layer 4, the second conductive layer 4 is arranged between the radiation enhancement layer 3 and the second insulating and water-proof layer 5, and the second conductive layer 4 is conductive graphite material.

[0039] The titanium nitride material or titanium carbide material is a...

Embodiment 2

[0049] This embodiment should be understood as including all the features of the foregoing embodiments, and further optimized on the basis thereof. Therefore, this embodiment provides a low-voltage infrared electrothermal film, which includes a first insulating and water-proof layer 1, The first conductive layer 2, the radiation enhancement layer 3 and the second insulating water-proof layer 5, the first insulating water-proof layer 1, the first conductive layer 2, the radiation enhancing layer 3 and the second insulating water-proof layer The water layers 5 are connected in sequence, and the first conductive layer 2 is a conductive graphite material, and the radiation enhancement layer 3 includes a titanium nitride material or a titanium carbide material.

[0050] The low-voltage infrared electric heating film also includes a second conductive layer 4, the second conductive layer 4 is arranged between the radiation enhancement layer 3 and the second insulating and water-proof ...

Embodiment 3

[0061] This embodiment should be understood as at least including all the features of any one of the preceding embodiments, and further optimized on the basis of it. Therefore, this embodiment provides a low-voltage infrared electrothermal film, the low-voltage infrared electrothermal film includes a first insulating water-proof layer 1, the first conductive layer 2, the radiation enhancing layer 3 and the second insulating water-proof layer 5, the first insulating and water-proof layer 1, the first conductive layer 2, the radiation enhancing layer 3 and the second The two insulating and water-proof layers 5 are connected in sequence, and the first conductive layer 2 is made of conductive graphite material, and the radiation enhancing layer 3 is made of titanium carbide material.

[0062] The low-voltage infrared electric heating film also includes a second conductive layer 4, the second conductive layer 4 is arranged between the radiation enhancement layer 3 and the second ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com