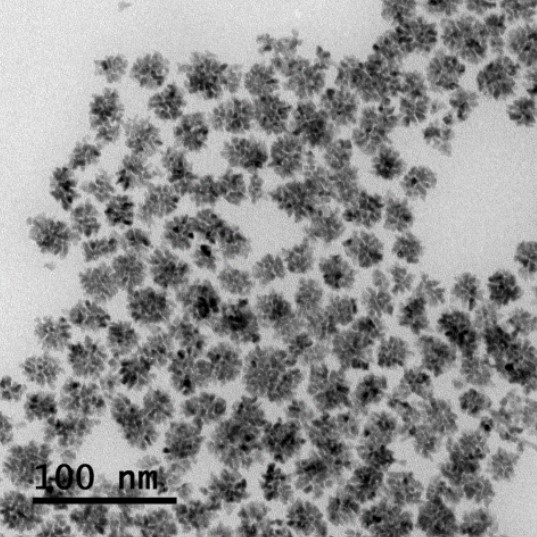

Preparation method of multi-layer nanoscale platinum-nickel alloy nano dendritic crystal material

A platinum-nickel alloy and multi-layer technology is applied in the field of preparation of platinum-nickel alloy nano-dendrites, which can solve problems such as difficulty in uniformity and unity, and achieve the effects of simple preparation method, mild reaction conditions, and uniform and regular morphology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method includes the following steps.

[0033] 1) At room temperature, mix nickel salt and surfactant in reducing solvent, then add platinum salt and stir for 10 minutes after ultrasonication for 30 minutes, so that the solvent and solute are fully mixed.

[0034] 2) Transfer the fully stirred mixed solution to the inner lining of polytetrafluoroethylene, add a magnetic stirring bar, put on the outer lining of the reaction kettle, and tighten the lid of the reaction kettle.

[0035] 3) Transfer the tightened reactor to an oil bath at a constant temperature of 180°C, and react for 12 hours. After the reaction was completed, the heating device was turned off, and the reactor was cooled down to room temperature.

[0036] 4) Take out the black solution in the inner lining of the reaction kettle with a rubber dropper, transfer it to a centrifuge tube, then add a mixed cleaning solution of ethanol and n-hexane, and perform ultrasonic centrifugal cleaning, repe...

example 1

[0040] The implementation process of the method for preparing the multi-layered platinum-nickel alloy nano-dendrite material in this embodiment is as follows.

[0041] At room temperature, the nickel salt and the surfactant were thoroughly mixed in 10 mL of the reducing solvent dimethylformamide, and after ultrasonication for 30 minutes, the platinum salt was added and stirred for 10 minutes to mix thoroughly, wherein the molar ratio of the platinum salt to the nickel salt was 1: 5. The nickel salt is nickel acetate, the platinum salt is chloroplatinic acid, the dosage of chloroplatinic acid is 0.05 mol, the dosage of nickel acetate is 0.25 mol, and the surfactant is dodecyltrimethylammonium chloride, and the dosage is 250 mg.

[0042] Transfer the well-stirred mixed solution to the inner liner of polytetrafluoroethylene with a capacity of 20 mL, add a magnetic stirring bar, cover the outer liner of the reaction kettle, and tighten the lid of the reaction kettle.

[0043] Tra...

example 2

[0048] The implementation process of the method for preparing the multi-layered platinum-nickel alloy nano-dendrite material in this embodiment is as follows.

[0049] At room temperature, the nickel salt and the surfactant were thoroughly mixed in 10 mL of the reducing solvent dimethylformamide, and after ultrasonication for 30 minutes, the platinum salt was added and stirred for 10 minutes to mix thoroughly, wherein the molar ratio of the platinum salt to the nickel salt was 1: 4. The nickel salt is nickel acetate, the platinum salt is chloroplatinic acid, the amount of chloroplatinic acid is 0.05 mol, the amount of nickel acetate is 0.20 mol, and the surfactant is dodecyltrimethylammonium chloride, and the amount is 250 mg.

[0050]Transfer the well-stirred mixed solution to the inner liner of polytetrafluoroethylene with a capacity of 20 mL, add a magnetic stirring bar, cover the outer liner of the reaction kettle, and tighten the lid of the reaction kettle.

[0051] Tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com