System and method for preventing burning explosion of dust bin

A silo and dust technology, which is applied in the field of systems for preventing dust silo explosions, can solve problems such as the inability to completely eliminate static electricity, the inability to completely avoid explosion accidents, and the high risk of explosions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

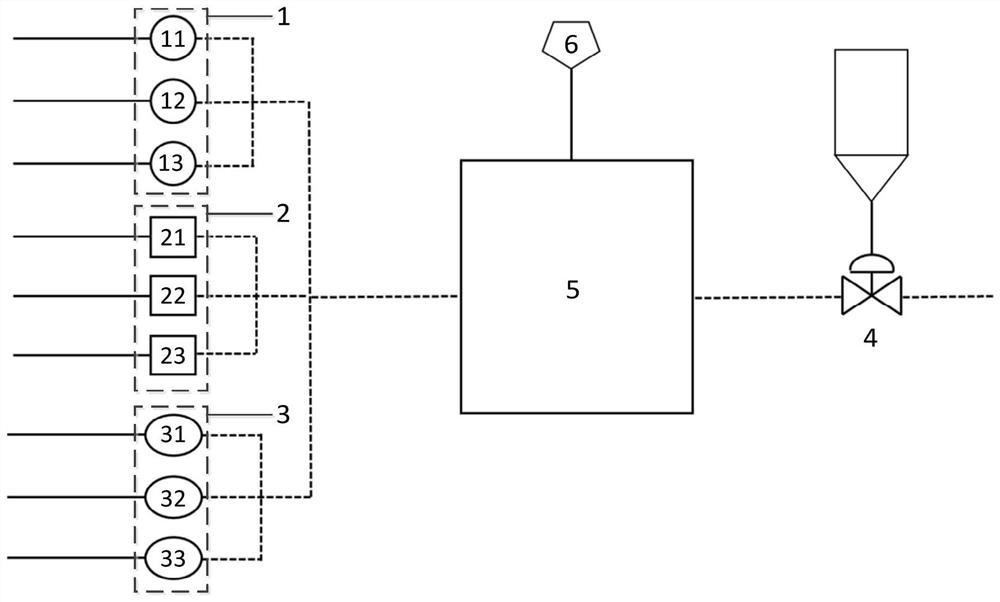

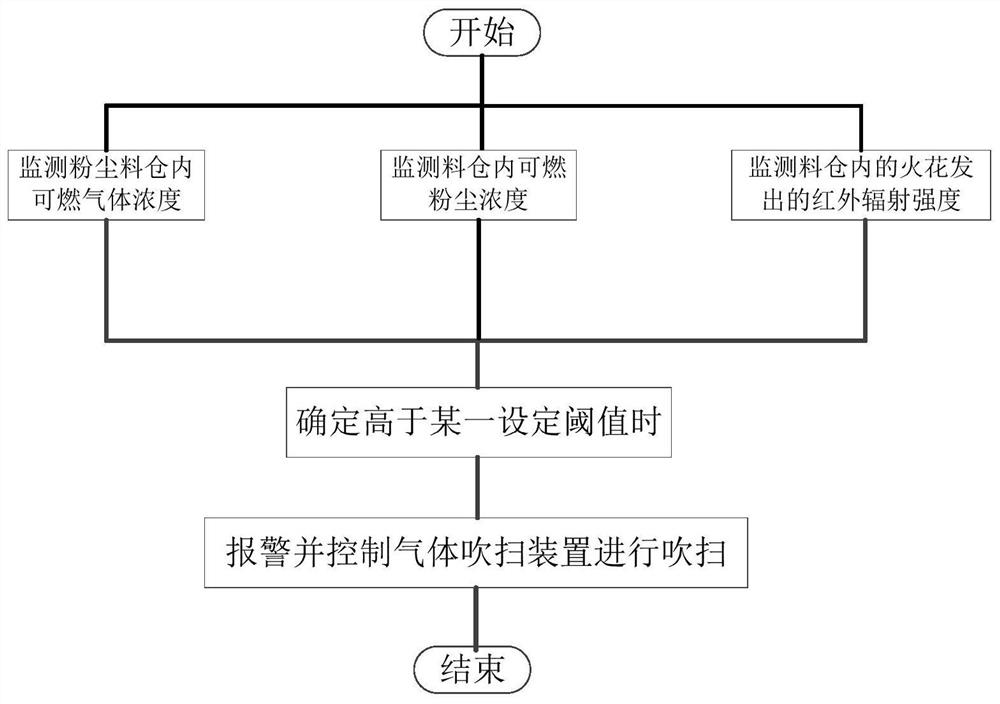

[0068] A silo stores low density polyethylene (LDPE) powder, the silo adopts figure 1 In the described system for preventing dust silo explosion, three groups of combustible gas concentration detectors 11, 12, 13 (specifically hydrocarbon detectors) and three groups of combustible powder concentration detectors are evenly arranged in the gas phase space at the top of the silo 1. 21, 22, 23 (specifically polyethylene dust concentration detectors) and three sets of spark detectors 31, 32, 33, can monitor the flammable gas and dust concentration and spark intensity at different positions on the top of the silo 1 in real time, and transmit the data to control unit 5. When the hydrocarbon detector detects that the ethylene concentration in the silo suddenly rises to 25% LEL, the alarm device 6 issues an alarm, and simultaneously opens the control valve on the gas purging device 4 (specifically, the nitrogen purging device), and nitrogen enters the silo. Replacement and inerting ar...

Embodiment 2

[0070] A silo stores low density polyethylene (LDPE) powder, the silo adopts figure 1 In the described system for preventing dust silo explosion, three groups of combustible gas concentration detectors 11, 12, 13 (specifically hydrocarbon detectors) and three groups of combustible powder concentration detectors are evenly arranged in the gas phase space at the top of the silo 1. 21, 22, 23 (specifically polyethylene dust concentration detectors) and three sets of spark detectors 31, 32, 33, can monitor the flammable gas and dust concentration and spark intensity at different positions on the top of the silo 1 in real time, and transmit the data to control unit 5. When the polyethylene powder in the silo is fed, the flow rate fluctuates suddenly, and then the polyethylene dust detector detects that the polyethylene concentration in the silo suddenly rises to 45% MEC, and the alarm device 6 issues an alarm, and at the same time automatically turns on the gas purge The control v...

Embodiment 3

[0072] A silo is used to store low density polyethylene (LDPE) powder. figure 1 In the described system for preventing dust silo explosion, three groups of combustible gas concentration detectors 11, 12, 13 (specifically hydrocarbon detectors) and three groups of combustible powder concentration detectors are evenly arranged in the gas phase space at the top of the silo 1. 21, 22, 23 (specifically polyethylene dust concentration detectors) and three sets of spark detectors 31, 32, 33 can monitor the concentration of combustible gas and dust and spark intensity at different positions on the top of the silo 1 in real time, and transmit the data to control unit 5. When a spark infrared signal (its intensity is 110 μJ) is suddenly detected in the silo, the alarm device 6 issues an alarm, and at the same time, the control valve on the gas purging device 4 (specifically, the nitrogen purging device) is automatically opened, and the nitrogen enters the silo. After replacement and in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com