Edible mushroom polysaccharide, and preparation method and application thereof

A technology for edible fungi and mushrooms, which is applied in the field of edible mushroom polysaccharide and its preparation, can solve the problems of poor anti-oxidation and anti-tumor activity, and achieve the effects of improving in vitro anti-oxidation, increasing added value and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

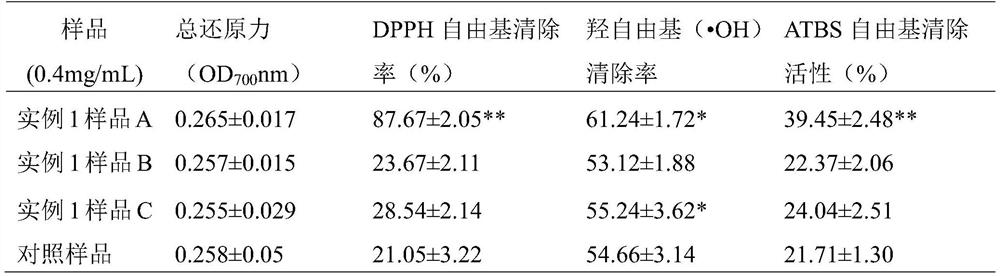

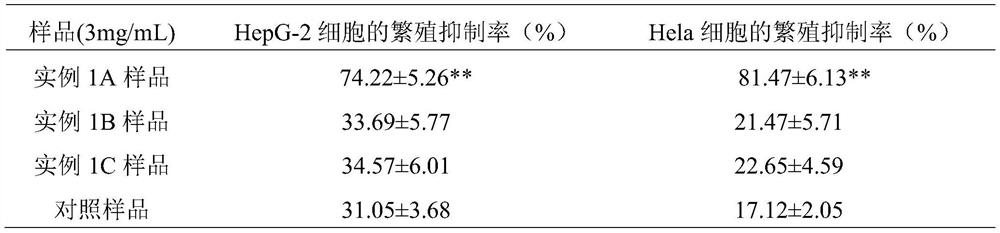

Embodiment 1

[0048] 1. A preparation method of mushroom edible fungus polysaccharide, comprising the steps of:

[0049] (1) Mushroom edible fungus pretreatment: take three portions of fresh Agaricus bisporus, 50g each, samples A, B and C respectively, wash with clean water and dry the surface moisture, take the stipe and cap of the edible fungus and grind them with a pulverizer Crumble into a homogenate, the particle size is about 100 mesh, add 0.1 times the quality of ultrapure water and mix to obtain a homogenate;

[0050] (2) Autolysis and enzymolysis of mushroom edible fungus: Put the homogenate in a water bath, keep sample A at 45°C for 6h, sample B at 45°C for 1.5h, and sample C at 30°C for 6h, and use Stir with a mixer at a stirring speed of 100r / min to obtain the edible fungi of autolyzed mushrooms;

[0051](3) Stop the autolysis of mushroom edible fungus: after the heat preservation is over, heat the autolyzed edible mushroom mushroom obtained in step (2) in a water bath at 100°C...

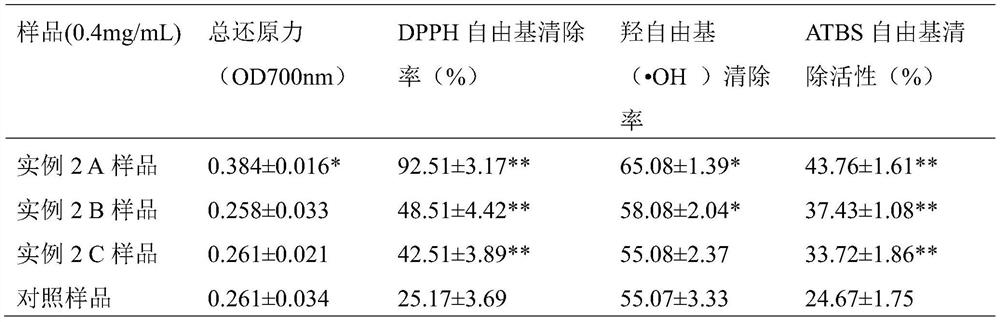

Embodiment 2

[0099] 1. A preparation method of mushroom edible fungus polysaccharide, comprising the steps of:

[0100] (1) Mushroom edible fungus pretreatment: take three parts of fresh Flammulina velutipes each 50g, which are samples A, B and C respectively, wash with clean water and dry the surface moisture, take the stipe and cap of edible fungus and grind them with a pulverizer Crumble into a homogenate, the particle size is about 50 mesh, add 1 times the quality of ultrapure water and mix to obtain a homogenate;

[0101] (2) Autolysis and enzymolysis of mushroom edible fungus: put the homogenate in a water bath, add 0.5% (w / v) mannanase to sample A, and add 0.5% (w / v) cellulose to sample B Enzyme, add 0.5% (w / v) pectinase to sample C, incubate at 50°C for 2 hours, and stir with a mixer at a stirring speed of 120r / min, to obtain autolytic mushroom edible fungus;

[0102] (3) Stop the autolysis of mushroom edible fungus: After the heat preservation is over, heat the autolyzed mushroom...

Embodiment 3

[0115] A preparation method of mushroom edible fungus polysaccharide, comprising the steps of:

[0116] (1) Mushroom pretreatment: take three parts of fresh shiitake mushrooms, 50g each, wash with water and dry the surface moisture, take the stipe and cap of the edible fungi and crush them into a homogenate with a particle size of about 10 Add 5 times the mass of ultrapure water and mix to obtain a homogenate;

[0117] (2) Autolysis and enzymolysis of mushroom edible fungus: Put the homogenate in a water bath, add 0.5% (w / v) dextranase, keep the A sample at 40°C for 8h, and the B sample at 40°C Insulate for 16 hours, C sample is incubated at 55°C for 8 hours, and stirred with a mixer at a stirring speed of 180r / min;

[0118] (3) Stop the autolysis of edible mushrooms: after the heat preservation, heat in a water bath at 100°C for 10 minutes to inactivate the enzyme activity, stop the autolysis of mushrooms, and obtain a solution of edible mushrooms after autolysis;

[0119] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com