Wet-type desulfurization and dust removal tower

A technology for wet desulfurization and dust removal towers, which is applied in the separation of dispersed particles, chemical instruments and methods, combined devices, etc., can solve the problems of poor versatility of wet desulfurization and dust removal towers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

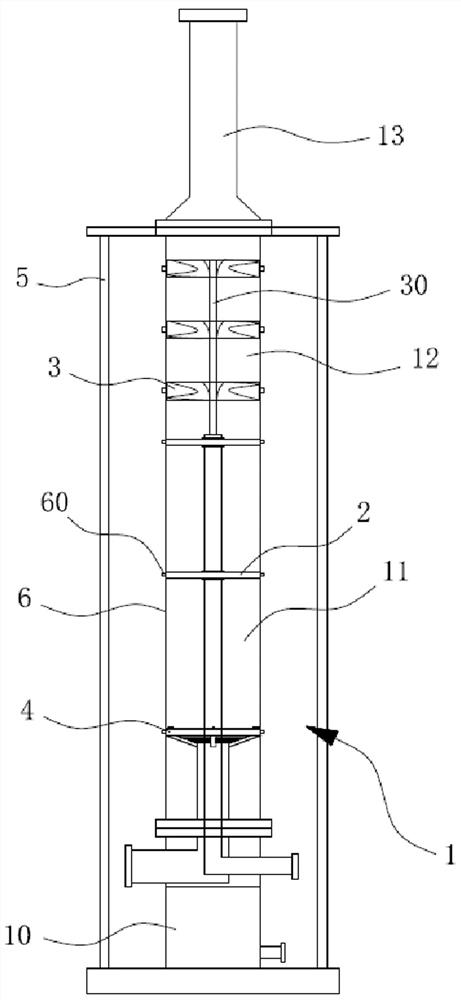

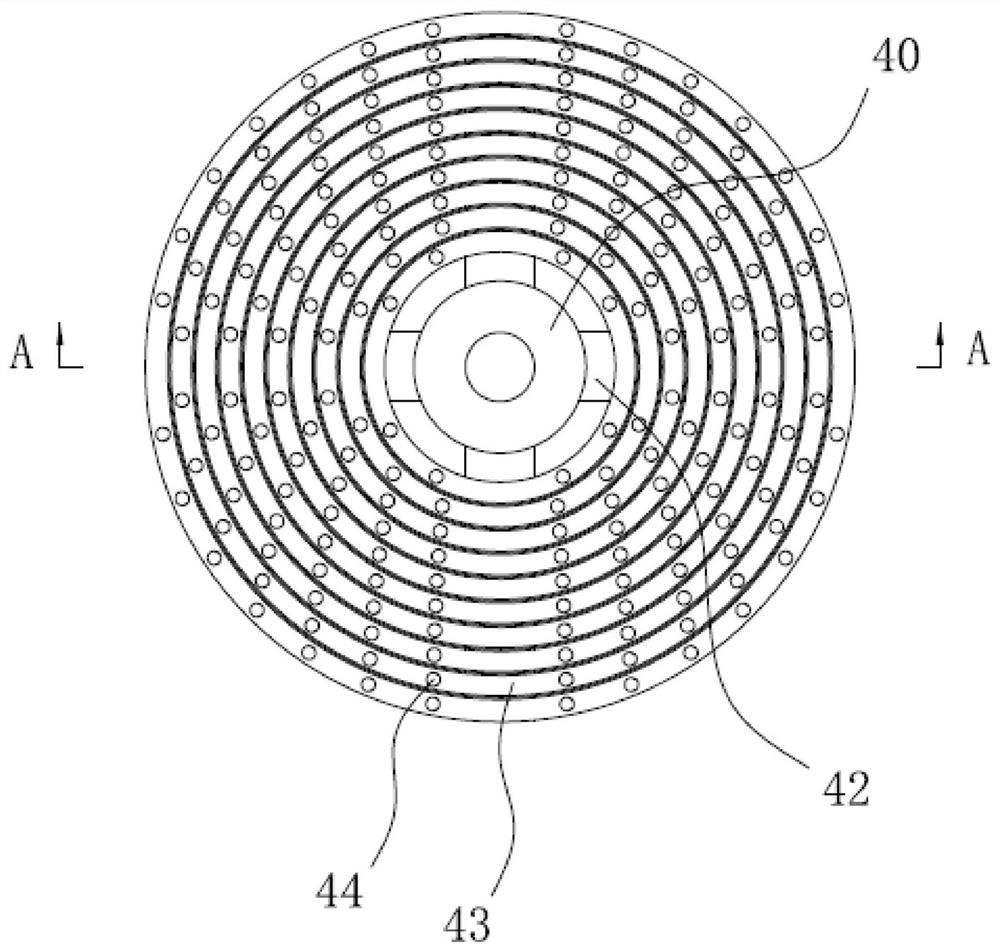

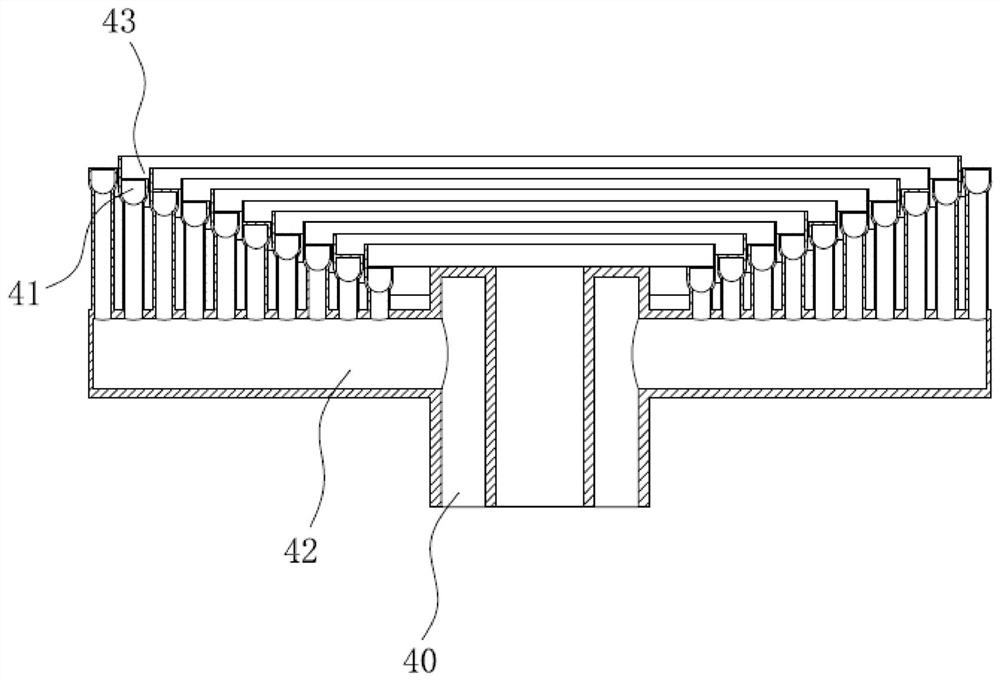

[0032] Such as figure 1 As shown, the wet desulfurization and dust removal tower includes a tower body 1, and the tower body 1 includes a liquid holding section 10, a desulfurization section 11, a dust removal section 12, and a straight discharge section 13 from bottom to top. The atomizing spray assembly 2, the atomizing spray assembly 2 is connected to the lye pool through the liquid inlet pipe, and several vertically spaced mist eliminators 3 are arranged in the dust removal section 12, and the mist eliminator 3 is preferably a swirl plate. The tower body 1 is equipped with a gas distribution device 4, the gas distribution device 4 is connected to the exhaust gas source through a pipeline with a pump, the gas distribution device 4 is located between the desulfurization section 11 and the liquid holding section 10, and the pump body pumps the exhaust gas into the gas distribution device In 4, the gas distribution device 4 evenly distributes the exhaust gas to flow upward, an...

Embodiment 2

[0040] The difference between this embodiment and Embodiment 1 is that: Figure 7 As shown, the outlet of the liquid holding section 10 is connected to the inlet of the regeneration tank 7, the outlet of the regeneration tank 7 is connected to the inlet of the sedimentation tank 8, the outlet of the sedimentation tank 8 is connected to the inlet of the circulating water tank 9, and the outlet of the circulating water tank 9 is connected to the main A circulation pump 90 is installed on the liquid inlet pipe 20 and the circulation pipeline. The lye is stored in the liquid holding section 10 after reacting with the sulfur oxides in the exhaust gas, and the circulation pump 90 transports the solution in the liquid holding section 10 to the regeneration pool 7, and then regenerates it under heating conditions by adding oxygen and catalyst. After the solution enters the sedimentation tank 8, the impurities in the solution are precipitated, and the lye formed after the treatment ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com