Drilling and splitting excavation construction method

A construction method and scheme technology, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve the problems of tunnel noise and safety, and achieve the effects of reducing construction noise, ensuring construction safety, and reducing injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

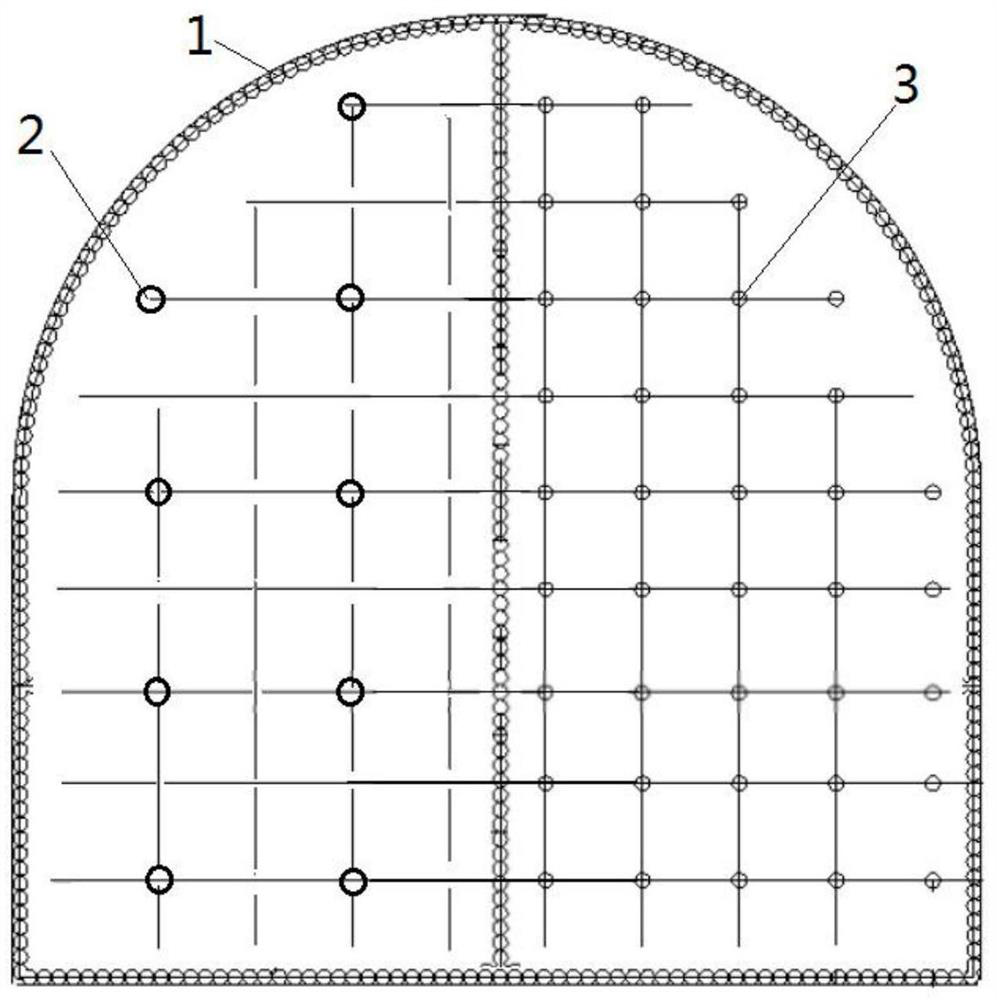

[0043] see Figure 1 to Figure 2 , a drilling and splitting excavation construction method, the present embodiment is applied to the tunnel drilling and splitting excavation construction at the entrance of the tunnel.

[0044] A drilling and splitting excavation construction method, using the drilling and splitting trolley in the Chinese patent application number 201910074591. The tensile strength is much smaller than the compressive strength characteristics. First drill the split hole, and then extend the splitting rod into the split hole to split (expand) the rock for rock-breaking excavation, which effectively solves the adverse effects of drilling and blasting excavation. A safe, stable and effective static pressure excavation method, under special geological conditions, is a supplement to the drilling and blasting method or an effective alternative to the excavation of short and medium length tunnels in hard rock. Include the following steps:

[0045] Drilling holes in ...

Embodiment 2

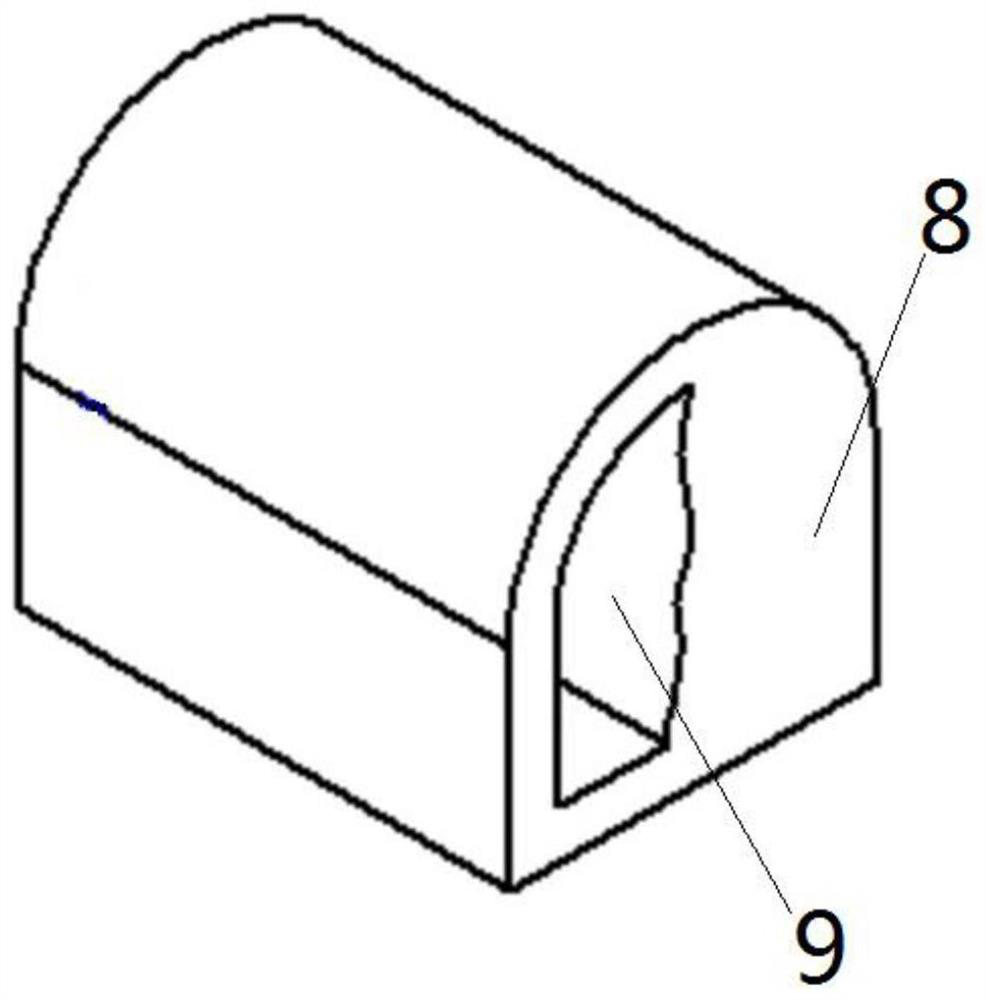

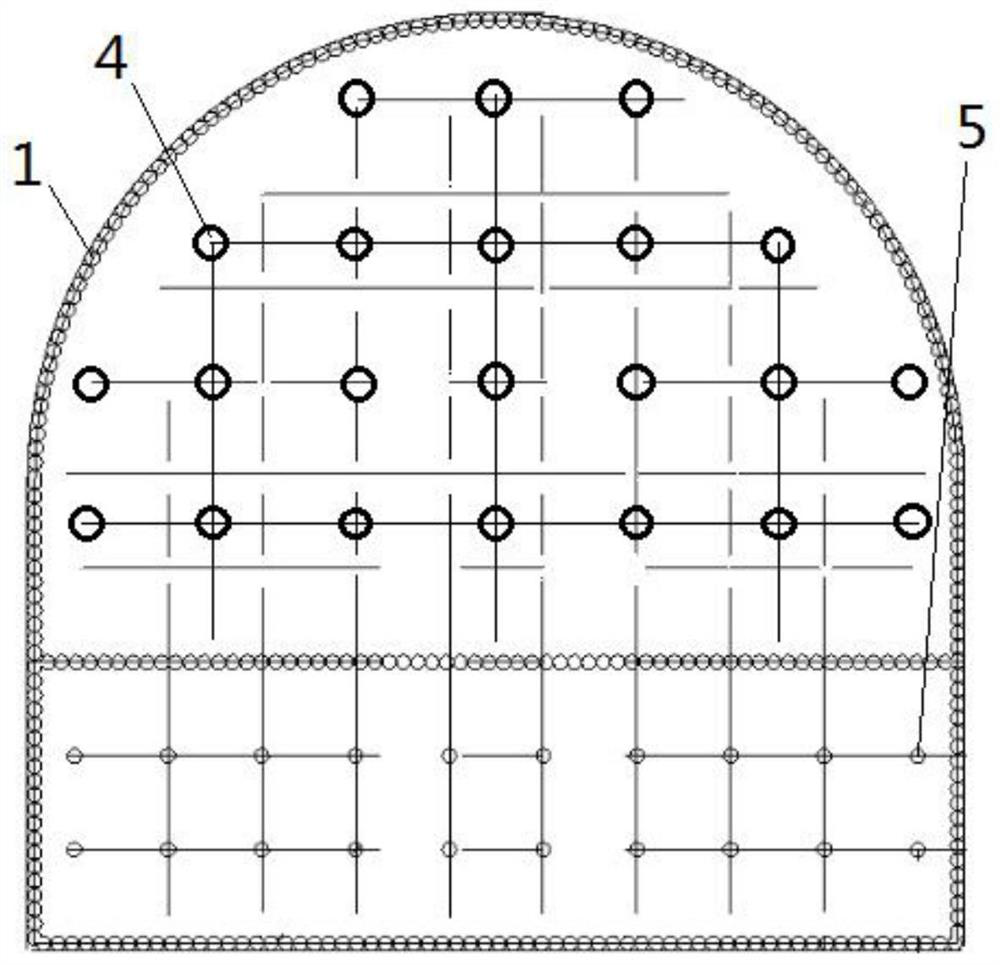

[0064] see Figure 3 to Figure 4 , this embodiment is applied to the tunnel drilling and splitting construction in the middle of the tunnel. The difference between this embodiment and Embodiment 1 is that the rock grade of the face 8 is measured, the rock grade of the upper part of the face 8 is grade IV, the rock grade of the lower part of the face 8 is grade II, and vertical drilling is adopted. In the excavation scheme, a horizontal row of empty layer holes 1 is drilled along the upper and lower boundaries of the tunnel face 8 in the horizontal direction, and the upper area of the tunnel face 8 is selected as the initial excavation area.

[0065] In this embodiment, the rock grade at the upper part of the face 8 is grade IV, and the rock grade at the lower part of the face 8 is grade II. Therefore, the hole layout scheme 2 is adopted in the drilling and splitting area at the upper part of the face 8, and the split holes 3 and 4 are used. The hole diameter is 76mm, and th...

Embodiment 3

[0071] see Figure 5 to Figure 6 , this embodiment is applied to the tunnel drilling and splitting excavation construction of the deep buried section of the tunnel. The difference between this embodiment and Embodiment 1 is that the rock grade of the face 8 is measured, and the rock grade of the face 8 is evenly distributed. The rock grade is Class I, and the construction is difficult. The excavation scheme of circular drilling is adopted, and the hole 1 for the air layer is intensively drilled along the circular trajectory line 7 at the center of the face 8. The diameter of the outer circular trajectory line 7 is 700mm.

[0072] In this embodiment, hole layout scheme 1 is adopted on the face 8, the diameter of split hole 5 6 is 65 mm, and the distance between adjacent split holes 5 6 is 350 mm; Figure 5 shown.

[0073] The densely drilled area with the circular trajectory line 7 on the tunnel face 8 is selected as the initial excavation area, and the tunnel boundary and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com