Sulfur-doped pre-lithiated silicon-carbon composite material and preparation method thereof

A technology of carbon composite materials and pre-lithiated silicon, which is applied in the field of sulfur-doped pre-lithiated silicon-carbon composite materials and its preparation, can solve problems such as poor structural stability, poor cycle performance, and poor electronic conductivity, and achieve structural stability High performance, high specific capacity, and improved electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

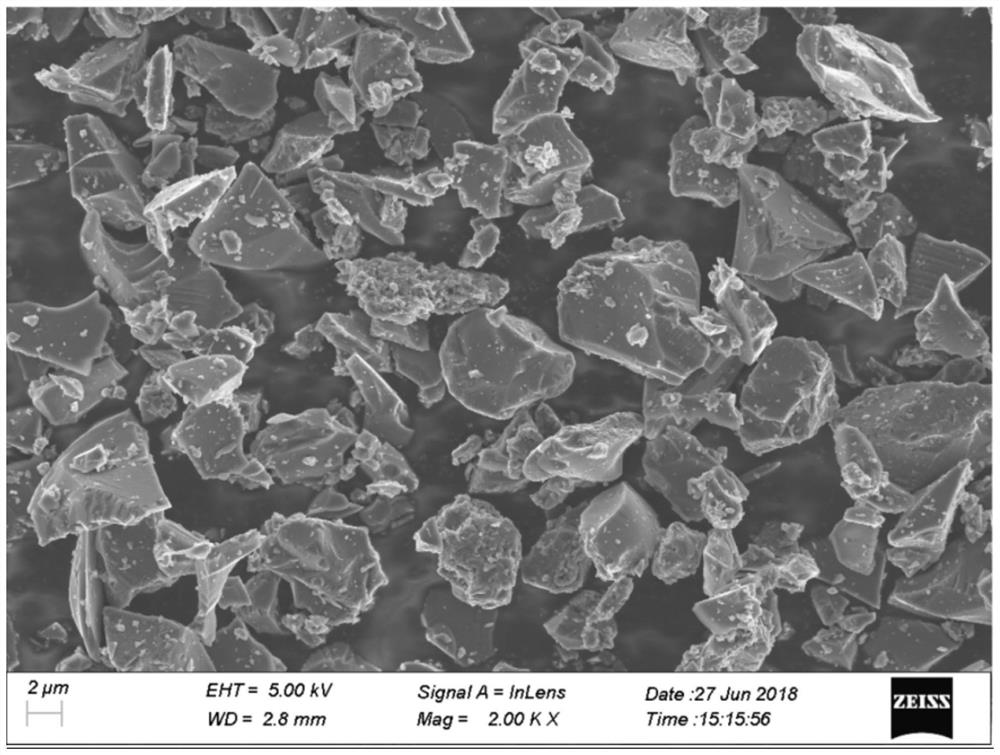

Image

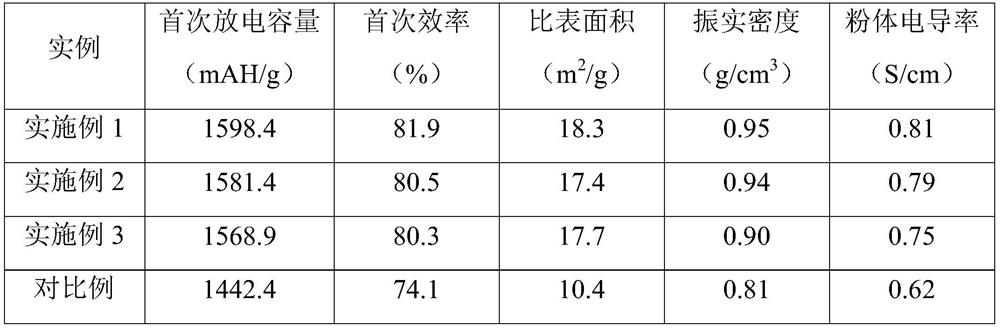

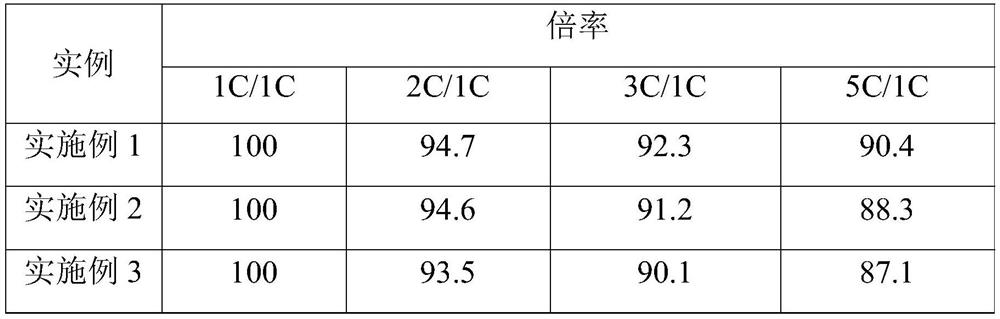

Examples

Embodiment 1

[0026] This embodiment provides a method for preparing a sulfur-doped pre-lithiated silicon-carbon composite material, comprising the following steps:

[0027] (1) 10g methionine is added to the 100g graphene oxide N-methylpyrrolidone solution with a concentration of 0.5wt.%, and the solution a is obtained after uniform stirring; wherein, the common proportion of hydroxyl and carboxyl groups in graphene oxide is 1%.

[0028] (2) Add 3g of tert-butyllithium and 100g of N-methylpyrrolidone solvent to solution a obtained in step (1), seal and stir to obtain solution b;

[0029] (3) Add 100g of silicon monoxide to 300g of solution b and stir evenly, then transfer to a high-pressure reactor, and react at 180°C and 3Mpa for 12h, then filter and dry at 80°C for 12h to obtain a composite material Intermediate;

[0030] (4) Transfer the composite material intermediate obtained in step (3) to a tube furnace, and in an argon inert atmosphere, heat up to 900°C at a heating rate of 5°C / m...

Embodiment 2

[0032] This embodiment provides a method for preparing a sulfur-doped pre-lithiated silicon-carbon composite material, comprising the following steps:

[0033] (1) Add 10g cysteine to the 100g graphene oxide N-methylpyrrolidone solution with a concentration of 0.1wt.%, and stir uniformly to obtain solution a; wherein, the common proportion of hydroxyl and carboxyl in graphene oxide is 0.5%.

[0034] (2) Add 1g of lithium n-butoxide and 100g of carbon tetrachloride solvent to solution a obtained in step (1), and obtain solution b after sealing and stirring;

[0035] (3) Add 100g of silicon monoxide to 100g of solution b and stir evenly, then transfer to a high-pressure reactor, and react at 100°C and 1Mpa for 24h, then filter and dry at 80°C for 12h to obtain a composite material Intermediate;

[0036] (4) Transfer the composite material intermediate obtained in step (3) to a tube furnace, and in an argon inert atmosphere, heat up to 800°C at a heating rate of 5°C / min for c...

Embodiment 3

[0038] This embodiment provides a method for preparing a sulfur-doped pre-lithiated silicon-carbon composite material, comprising the following steps:

[0039] (1) Add 10g of 2-mercaptoethanol to a 100g graphene oxide N-methylpyrrolidone solution with a concentration of 1wt.%, and stir uniformly to obtain solution a; wherein, the proportion of hydroxyl and carboxyl groups in graphene oxide is 2 %.

[0040] (2) Add 5g of n-butyllithium and 100g of tetrahydrofuran solvent to solution a obtained in step (1), seal and stir to obtain solution b;

[0041] (3) Add 100g of silicon monoxide to 500g of solution b and stir evenly, then transfer to a high-pressure reactor, and react at 200°C and 5Mpa for 1h, then filter and dry at 80°C for 12h to obtain a composite material Intermediate;

[0042] (4) Transfer the composite material intermediate obtained in step (3) to a tube furnace, and in an argon inert atmosphere, heat up to 1100°C at a heating rate of 5°C / min for carbonization for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com