Preparation method of photocatalytic material BiOBr/ZnSn(OH)6@carbon fiber cloth

A photocatalytic material and carbon fiber cloth technology, which can be used in catalyst activation/preparation, chemical instruments and methods, chemical/physical processes, etc., and can solve problems such as difficulty in recycling photocatalytic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: the photocatalytic material BiOBr / ZnSn(OH) of the present embodiment 6 The preparation method of @carbon fiber cloth is carried out according to the following steps:

[0025] (1) Pretreatment of carbon fiber cloth

[0026] Cut the carbon fiber cloth into small pieces of 4×4cm. The prepared mixed solution of water, ethanol, and acetone (the volume ratio of the three is 1:1:1) was ultrasonically treated for 30 minutes to remove the oily substances on the surface of the carbon fiber cloth. Put the carbon fiber cloth into aqua regia and soak for 24 hours to remove impurities such as metal and amorphous carbon on the surface of the carbon fiber cloth. The carbon fiber cloth was cleaned with deionized water and absolute ethanol, and dried in a blast drying oven for 4 hours at a temperature of 60 °C.

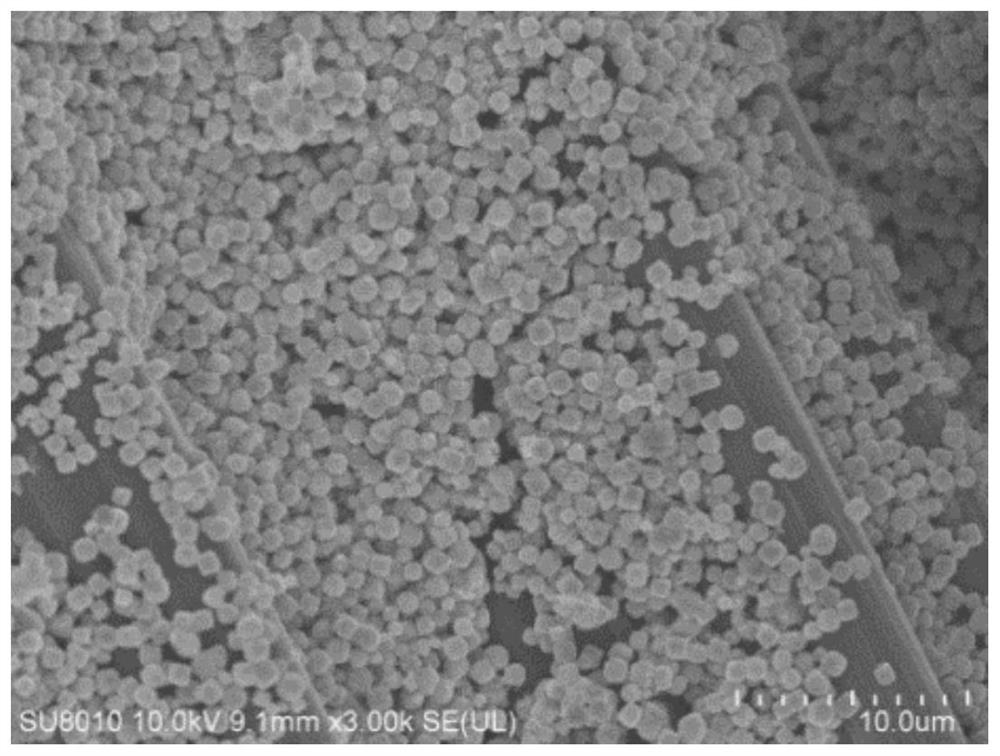

[0027] (2)ZnSn(OH) 6 @Preparation of carbon fiber cloth

[0028] 1.75g SnCl 4 ·5H 2 O and 0.68g ZnCl 2 Add 25mL of deionized water and stir to dissolve; ...

Embodiment 2

[0031] Embodiment 2: the photocatalytic material BiOBr / ZnSn(OH) of the present embodiment 6 The preparation method of @carbon fiber cloth is carried out according to the following steps:

[0032] (1) carbon fiber cloth pretreatment, the same as the first step of embodiment 1.

[0033] (2) Preparation of BiOBr@carbon fiber cloth

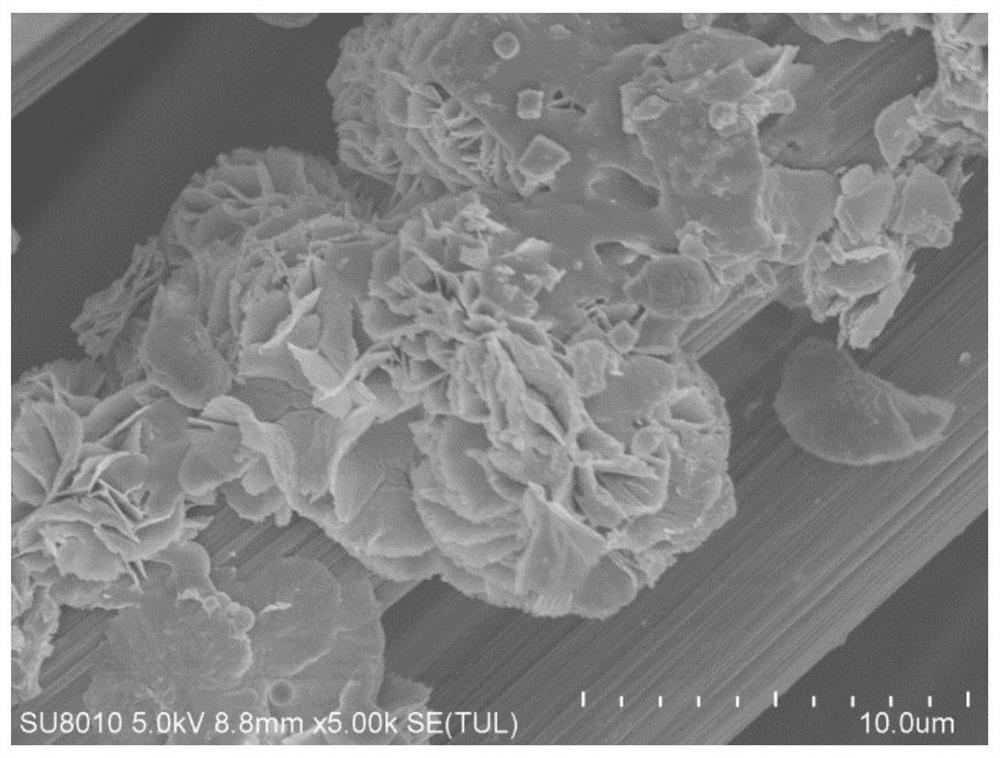

[0034] Weigh 0.485g Bi(NO 3 ) 3 ·5H 2 O and 0.357g KBr were dissolved in 40mL of ethylene glycol; the magnetic stirrer was continuously stirred for 30min; close to the bottom), static treatment for 30min; put the reaction kettle into a forced air drying oven for 12h at a temperature of 160°C. From figure 2 It can be seen from the scanning electron microscope image that the BiOBr is evenly distributed on the carbon fiber cloth, and the BiOBr is flower-shaped.

[0035] (3) Photocatalysis experiment

[0036] The catalytic performance of the sample is obtained by measuring the absorbance of the liquid. The degradation rate of BiOBr@carbon fiber cl...

Embodiment 3

[0037] Embodiment 3: the photocatalytic material BiOBr / ZnSn(OH) of the present embodiment 6 The preparation method of @carbon fiber cloth is carried out according to the following steps:

[0038] (1) carbon fiber cloth pretreatment, the steps are the same as the first step of embodiment 1.

[0039] (2)ZnSn(OH) 6 @ The preparation of carbon fiber cloth, the steps are the same as the second step of Example 1.

[0040] (3) BiOBr / ZnSn(OH) 6 @Preparation of carbon fiber cloth

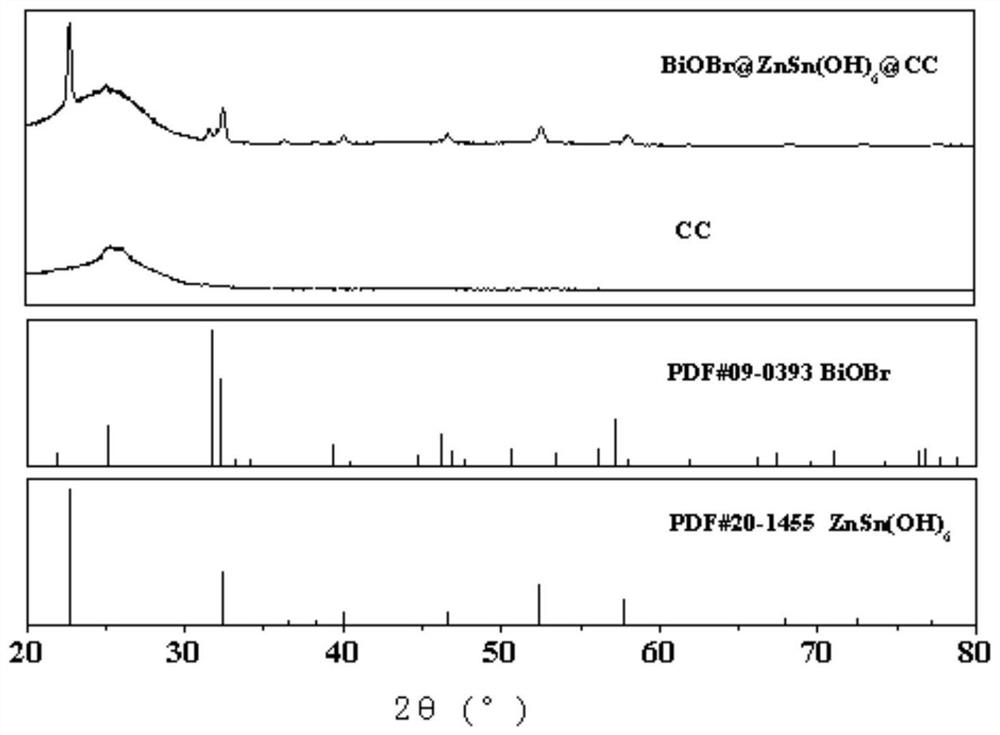

[0041] Weigh 0.820g Bi(NO 3 ) 3 ·5H 2 O and 0.607g KBr were dissolved in 40mL of ethylene glycol, and magnetically stirred for 30min to form a mixed solution; ZnSn(OH) 6 @Carbon fiber cloth and the mixed solution are put into the reaction kettle together for hydrothermal reaction at a temperature of 160°C for 12 hours. From Figure 4 It can be seen from the XRD data that pure BiOBr@ZnSn(OH) was successfully synthesized 6 composite material. From Figure 4 It can be seen that the successfully synt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com