Method for preparing Ti2AlC complex part by combining in-situ selective laser forming with reactive sintering

A technology of laser selection and reaction, which is applied in the field of in-situ laser selection forming combined with reaction sintering to prepare Ti2AlC complex parts, which can solve the problems of weak reaction between TiC and TiAl, insufficient reaction thermodynamic driving force, short laser action time, etc., and achieve clean bonding interface , Reduce production cost, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

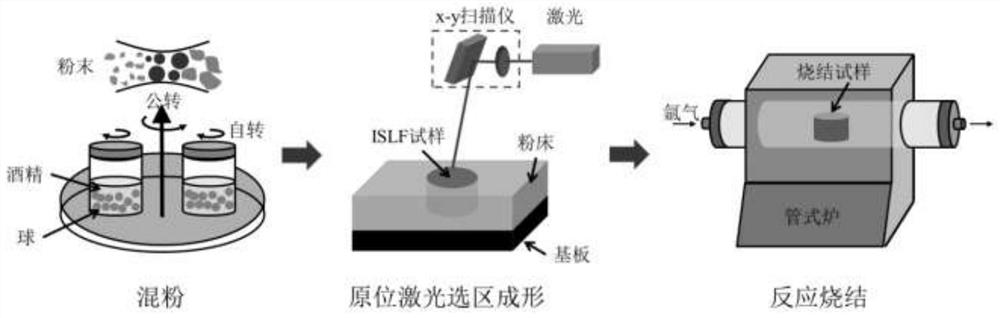

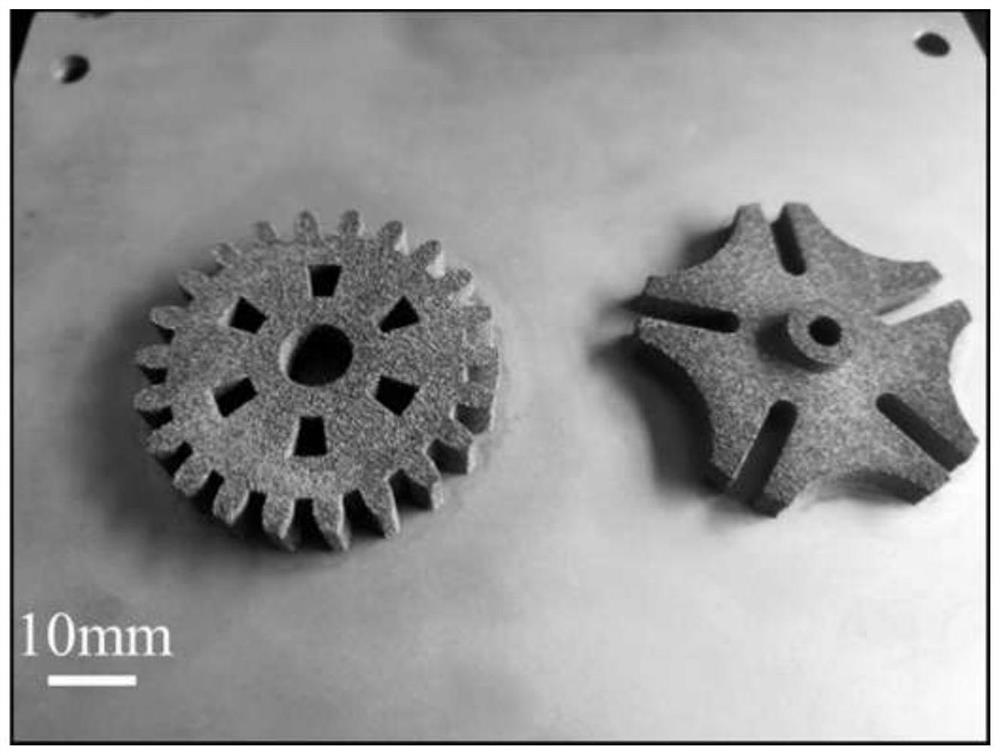

[0026] See figure 1 , This embodiment relates to an in-situ laser selective forming combined with reaction sintering to prepare Ti 2 The method of AlC complex parts includes the following steps:

[0027] (1) According to Ti 2 The composition of AlC Weigh titanium powder, aluminum powder, and graphite powder into a ball milling tank at a predetermined mass ratio, and add the ball to the milling ball at a ball-to-material ratio of 6:1, ball mill at a speed of 150r / min for 4 hours, and then dry and sieve A mixed powder is obtained. figure 2 The morphology and phase composition of the composite powder obtained by mixing are shown.

[0028] In this embodiment, the mixed powder consists of 71.1% by mass of titanium powder, 20.0% by mass of aluminum powder, and 8.9% by mass of graphite powder. The titanium powder is a spherical-like titanium powder with an average particle diameter of 1 μm, the aluminum powder is a spherical aluminum powder with an average particle diameter of 30 μm, and...

Embodiment 2

[0034] This embodiment relates to an in-situ laser selective forming combined with reaction sintering to prepare Ti 2 The AlC method includes the following steps:

[0035] (1) According to Ti 2 The composition of AlC Weigh titanium powder, aluminum powder, graphite powder and titanium carbide powder in a predetermined mass ratio into the ball milling tank, and add the ball to the milling ball at a ball-to-battery ratio of 8:1. After ball milling at a speed of 200r / min for 4h Drying and sieving to obtain mixed powder.

[0036] In this embodiment, the mixed powder is composed of 64.0% by mass titanium powder, 20.0% by mass aluminum powder, 7.1% by mass graphite powder, and 8.9% by mass titanium carbide powder. The titanium powder is a spherical-like titanium powder with an average particle diameter of 1 μm, the aluminum powder is a spherical aluminum powder with an average particle diameter of 20 μm, and the graphite powder is an irregular graphite powder with an average particle dia...

Embodiment 3

[0042] This embodiment relates to an in-situ laser selective forming combined with reaction sintering to prepare Ti 2 The AlC method includes the following steps:

[0043] (1) According to Ti 2 The composition of AlC Weigh titanium powder, aluminum powder, graphite powder and titanium carbide powder into a ball milling tank at a predetermined mass ratio, and add the ball to the grinding ball at a ball-to-battery ratio of 6:1. After ball milling at a speed of 150r / min for 4h Drying and sieving to obtain mixed powder.

[0044] In this embodiment, the mixed powder is composed of 49.8% by mass of titanium powder, 20.0% by mass of aluminum powder, 3.5% by mass of graphite powder, and 26.7% by mass of titanium carbide powder. The titanium powder is a spherical-like titanium powder with an average particle size of 1 μm, the aluminum powder is a spherical aluminum powder with an average particle size of 40 μm, and the graphite powder is an irregular graphite powder with an average particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com