Silicon carbide single crystal growth device

A silicon carbide single crystal and growth device technology, applied in the directions of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems that are not conducive to the preparation of silicon carbide crystals, uneven distribution of gas phase components, uneven radial heat transfer, etc. problems, to achieve the effect of reducing impurities and defects, improving crystal quality, and heating uniformly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

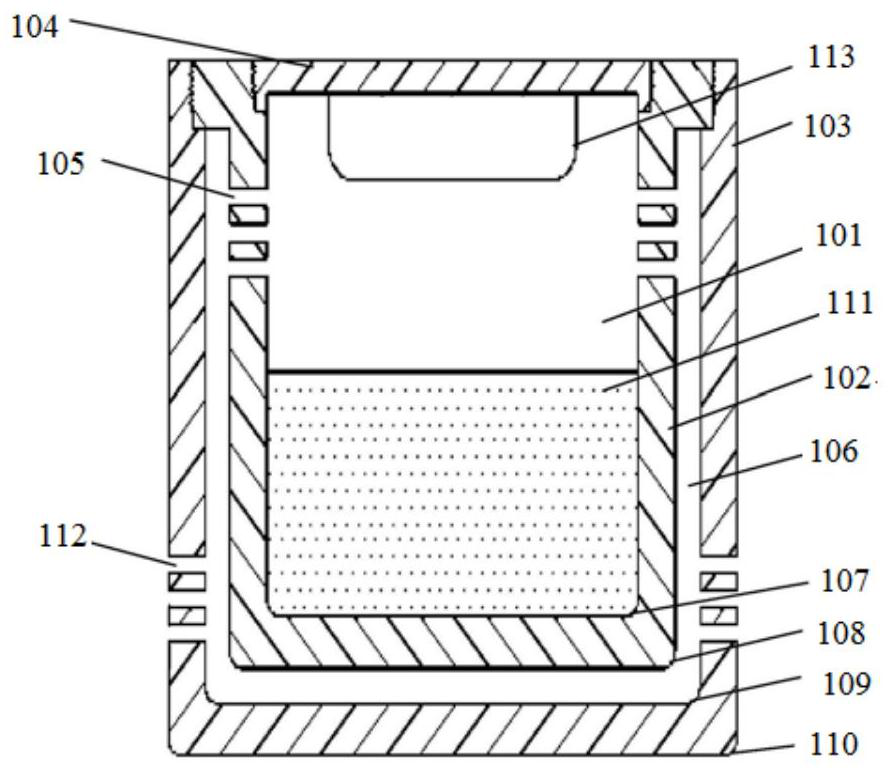

[0034] Such as figure 1 As shown, an existing silicon carbide single crystal growth device includes: a chamber 101, a first wall 102, a second wall 103, a cover 104, a plurality of first openings 105, a first space 106, a first Inner bottom corner 107 of the layer wall, outer bottom corner 108 of the first layer wall, inner bottom corner 109 of the second layer wall, outer bottom corner 110 of the second layer wall, material 111, second opening 112 and grown silicon carbide single crystal 113 . The purpose of this device is to pass through high-purity silane by setting the second opening 112 and the first opening 105, and react with the remaining fluffy carbon powder after carbonization to form silicon carbide powder again, so as to realize the continuous growth of single crystal and improve the crystal quality .

[0035] In this device, high-purity silane gas is introduced from the outside by setting the first opening 105 and the second opening 112, and the gas passage need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com