A low temperature attitude control engine propellant supply pipeline system

A technology of attitude control and supply pipeline, which is applied in the direction of machine/engine, rocket engine device, jet propulsion device, etc., which can solve the problems such as the inability to propel the service life of the system and the inability of the cooling structure to adjust the pre-cooling under multiple working conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

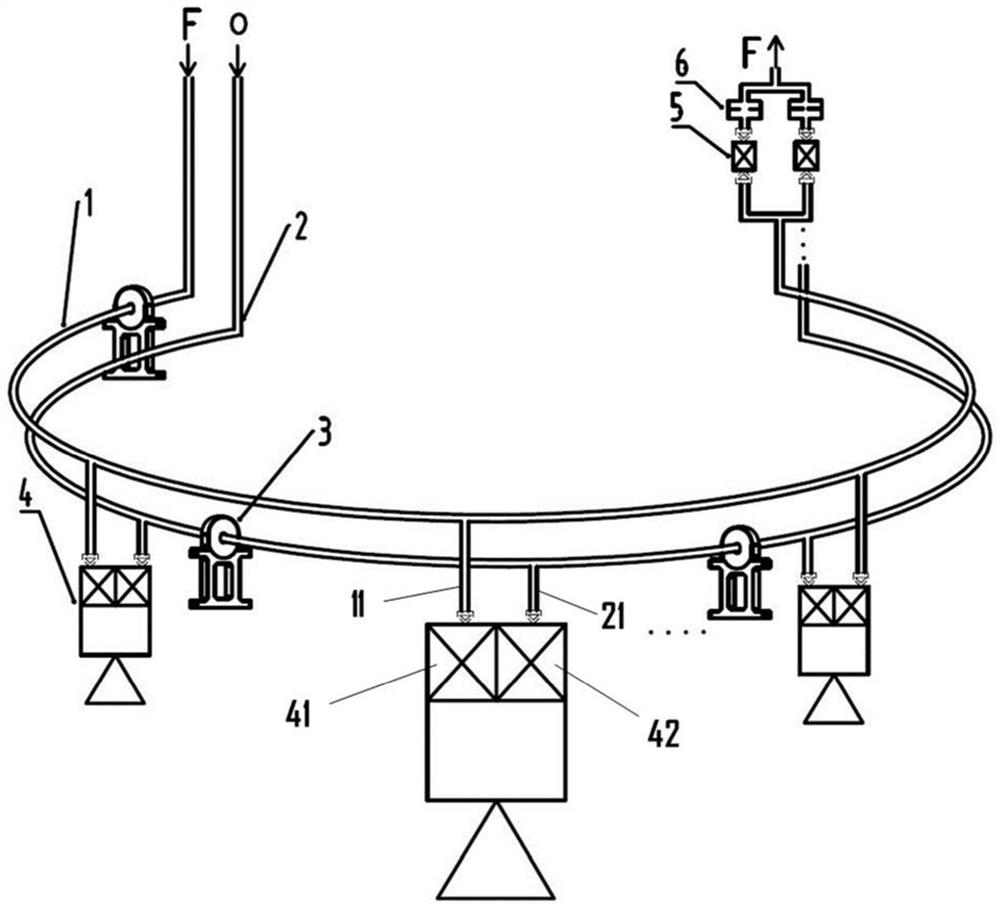

[0029] A low-temperature attitude control engine propellant supply pipeline system, including a low-temperature fuel annular pipeline 1, a low-temperature oxidant annular pipeline 2, a low-temperature heat insulation bracket 3, a low-temperature attitude control engine 4, a control valve 5, and a throttle orifice 6. The low-temperature fuel annular pipeline 1 and the low-temperature oxidant annular pipeline 2 are connected and fixed to the propulsion system assembly structure through the low-temperature heat insulation bracket 3, and the low-temperature attitude control engine 4 is connected to the low-temperature fuel annular pipeline through the low-temperature fuel control valve 41. The pipeline 1 is connected to the low-temperature oxidant annular pipeline 2 through the low-temperature oxidant control valve 42. The end of the low-temperature fuel annular pipeline 1 is provided with multiple bifurcated branches, and each bifurcated branch is provided with a control valve. 5....

Embodiment 2

[0033] Embodiment 2 is a preferred example of embodiment 1:

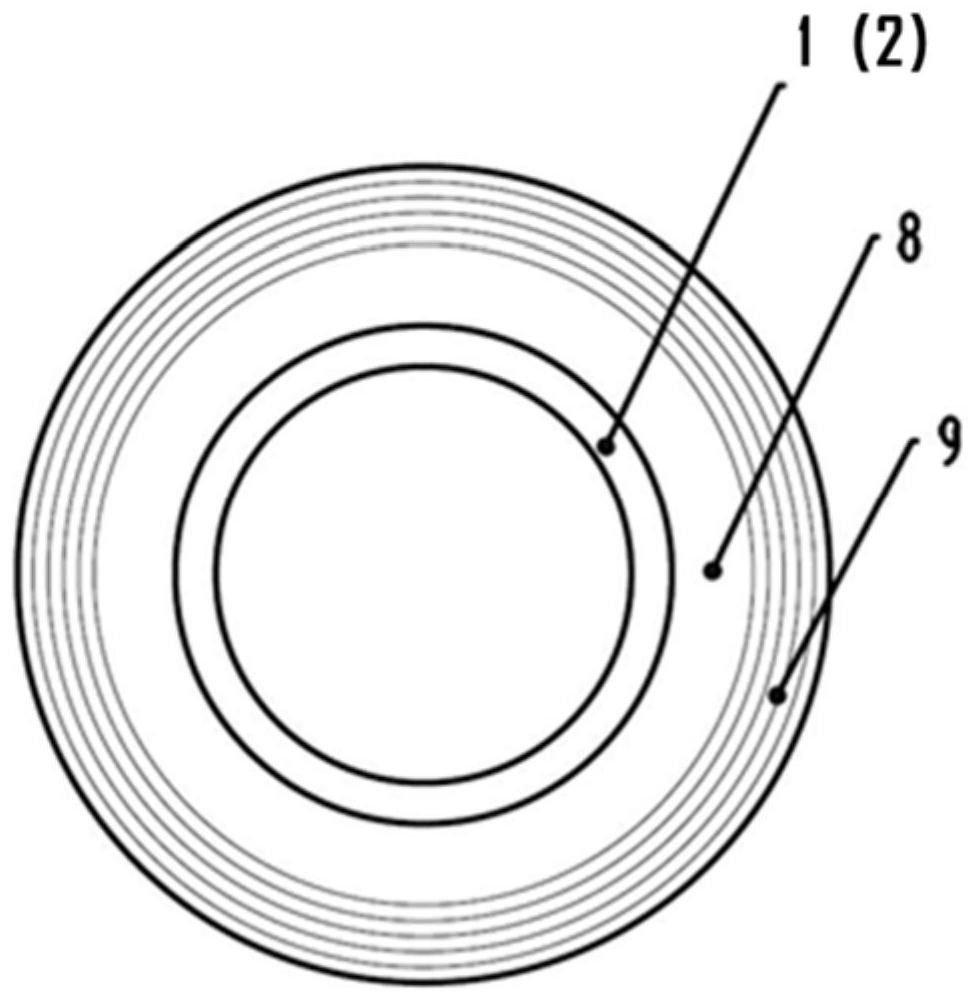

[0034] In Example 2, the surfaces of the low-temperature fuel annular pipeline 1 and the low-temperature oxidant annular pipeline 2 are covered with foam material 8 and multi-layer heat insulating material 9 . The foam material 8 can be polyurethane foam or airgel foam, and the multi-layer insulation material 9 is generally composed of high-reflectivity materials (usually double-sided aluminized film) and polyester nets laid alternately.

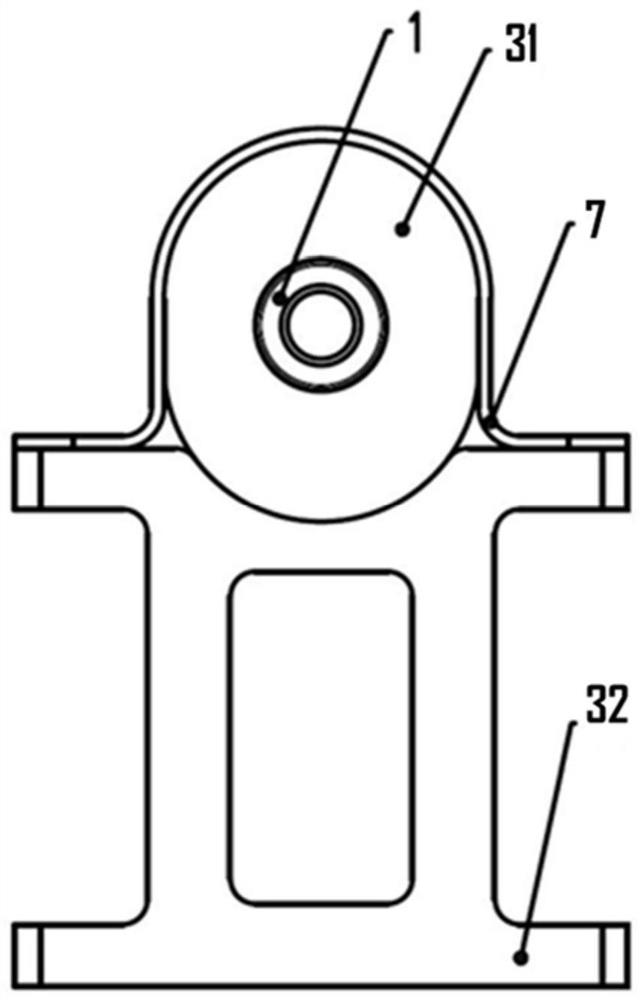

[0035] The low temperature heat insulation bracket 3 is composed of parts using different materials, including the pipeline fixing part 31 and the assembly connecting part 32. The pipeline fixing part 31 is a waist-shaped structure with a through hole in the middle, and the pipeline fixing part 31 is made of low temperature resistant materials. The assembly connection part 32 is an I-shaped structure with a vertical waist-shaped hole in the middle, the bottom of the assembly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com