Non-contact conductivity measurement device and method based on LC circuit

A conductivity measurement, non-contact technology, applied in the direction of fluid resistance measurement, etc., can solve the problems that the conductive solution can no longer be equivalent to a resistance, the bandwidth is required, and the measurement model is complicated, so as to facilitate the design, reduce the bandwidth requirement, The effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

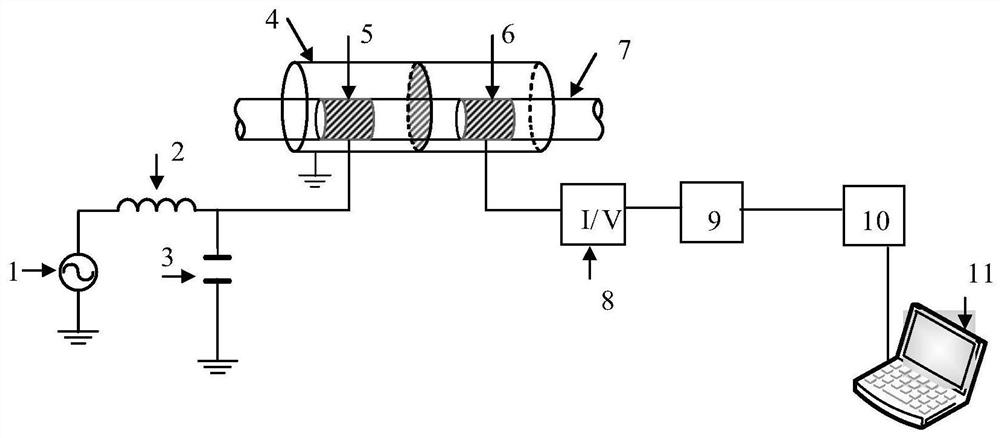

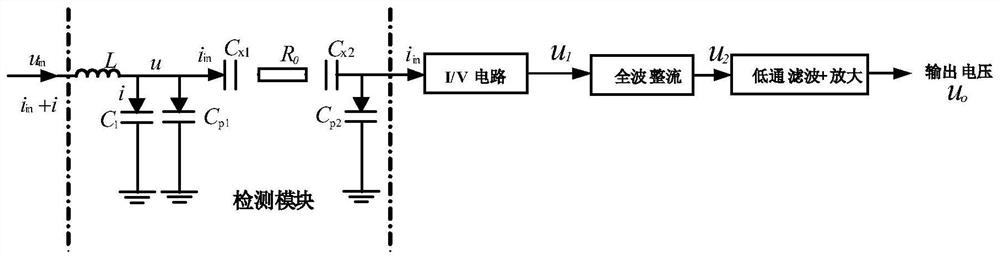

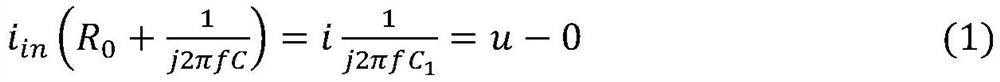

[0023] Such as figure 1 As shown, a non-contact conductivity measurement device based on LC circuit, including AC excitation source 1, inductance module 2, capacitor 3, metal shield 4, excitation electrode 5, detection electrode 6, insulating pipe 7, current-to-voltage module 8. Signal processing module 9, data acquisition module 10, computer 11; excitation electrode 5 and detection electrode 6 are arranged on the outer wall of insulating pipe 7; metal shield 4 is arranged on the periphery of excitation electrode 5 and detection electrode 6 for shielding electromagnetic influence ; The AC excitation source 1 is connected to one end of the inductance module 2, the other end of the inductance module 2 is connected to the excitation electrode 5, and is also connected to one end of the capacitor 3, and the other end of the capacitor 3 is connected to the ground; the detection electrode 6 is connected to the current switch The input ends of the voltage module 8 are connected, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap