Asymmetric-structure high-power laser with Bragg reflector and preparation method thereof

A technology of high-power lasers and Bragg mirrors, applied in the field of lasers, can solve problems such as internal quantum efficiency reduction, working temperature sensitivity, and sensitive memory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

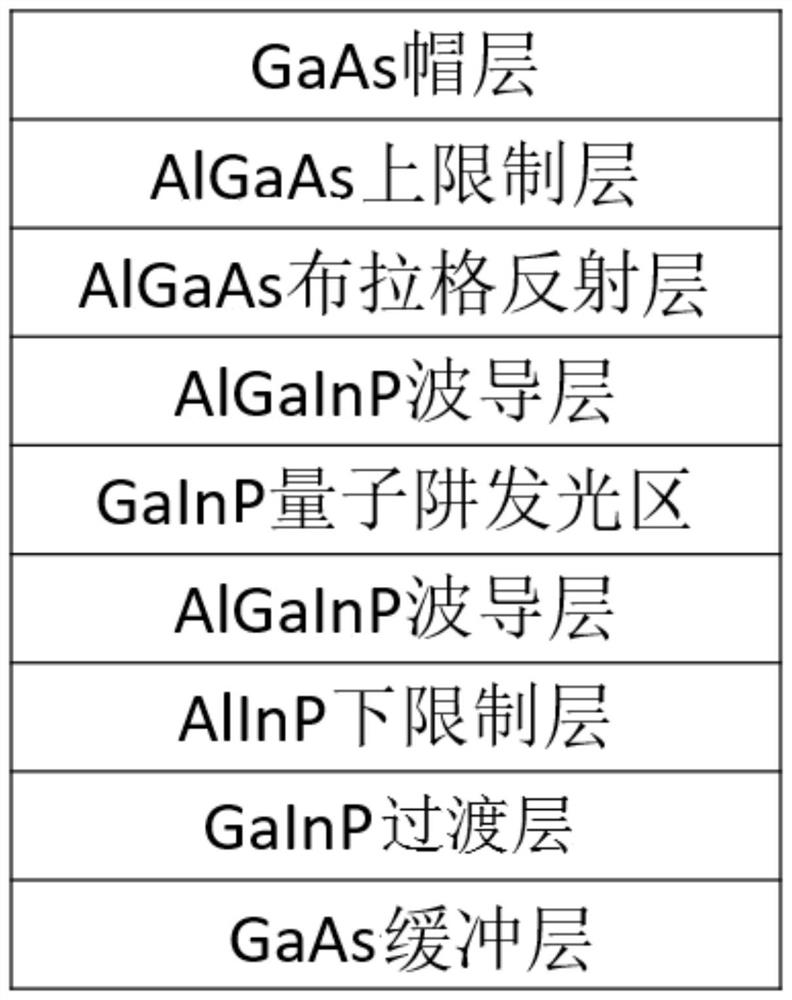

[0056] An asymmetric high-power laser with a Bragg reflector, such as figure 1 As shown, the GaAs substrate is included, and the GaAs buffer layer, GaAs buffer layer, Ga 1-x In x P transition layer, Al 1-x In x P lower confinement layer, (Al 1-x Ga x ) y In 1-y P lower waveguide layer, Ga 1-x In x P quantum well light-emitting region, (Al 1-x Ga x ) y In 1-y P upper waveguide layer, Al 1-x Ga x As Bragg reflector, Al 1-x Ga x As upper confinement layer and GaAs cap layer.

Embodiment 2

[0058] A kind of asymmetric structure high-power laser with Bragg reflector, structure as shown in embodiment 1, difference is, (Al 1-x Ga x ) y In 1-y The thickness of the waveguide layer under P is related to (Al 1-x Ga x ) y In 1-y The waveguide layers on P have different thicknesses, preferably 0.12 μm and 0.07 μm respectively.

Embodiment 3

[0060] A preparation method of an asymmetric structure high-power laser with a Bragg reflector, comprising the steps of:

[0061] (1) Put GaAs substrate in MOCVD equipment, H 2 The environment is heated to 720±10°C and baked for 30 minutes, and AsH is introduced 3 , remove water and oxygen on the surface of the GaAs substrate to complete the surface heat treatment, and prepare for step (2);

[0062] (2) Slowly lower the temperature to 700±10°C, and continue to feed TMGa and AsH 3 , grow a GaAs buffer layer with a thickness of 0.3 μm on the GaAs substrate;

[0063] (3) Keep the temperature at 700±10°C, continue to feed TMIn, TMGa and PH 3 , grow Ga on the GaAs buffer layer in step (2) 1-x In x P transition layer;

[0064] (4) Keep the temperature at 700±10°C, continue to feed TMIn, TMAl and PH 3 , Ga in step (3) 1-x In x Growth of n-type Al on P transition layer 1-x In x P lower limit layer;

[0065] (5) The temperature is lowered to 650±10°C, and TMIn, TMAl, TMGa a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com