A method for preparing curb stones from pavement recycled materials and the prepared curb stones

A technology of recycled materials and curbstones, applied in the direction of manufacturing tools, surface layering devices, sustainable waste treatment, etc., can solve the problems of increasing the cost of road surface, low content of old materials, affecting the surrounding environment, etc., to improve the resistance to salt freezing ability, make full use of waste materials, and avoid the effect of asphalt sticking to the pan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]A kind of curb stone prepared by using pavement recycled materials, which is made of the following components:

[0045] The mass ratio of RAP material is: 0-5mm: 40 parts, 5-12mm: 30 parts, 12-18mm: 30 parts; the amount of magnetizer accounts for 2wt.% of the RAP material; the magnetizer is made of steel fiber, and the length is 2-6mm , with a diameter of 400-800 μm; the amount of rock asphalt powder accounts for 5wt.% of the RAP material, and the particle size is 100-200 mesh.

[0046] The preparation steps include: mixing the above-mentioned mixed materials into a mold for electromagnetic heating, sealing and fixing the bottom and surroundings of the mold for electromagnetic heating, pressurizing the upper part, controlling the pressure to 4MPa, and controlling the temperature of electromagnetic heating to 150° C., the holding time is 7-9 seconds, and the curb stone body is obtained.

[0047] Using super-hydrophobic cement slurry to plaster the obtained curb body to o...

Embodiment 2

[0050] A kind of curb stone prepared by using pavement recycled materials, which is made of the following components:

[0051] The mass ratio of RAP material is: 0-5mm: 65 parts, 5-12mm: 15 parts, 12-18mm: 10 parts, 18-30mm: 10 parts; the amount of magnetizer accounts for 5wt.% of the RAP material, and the magnetizer is made of steel slag powder, 80-100 mesh; rock asphalt powder content accounts for 2wt.% of the RAP material, and the particle size is 100-200 mesh.

[0052] The preparation steps include: putting the above materials into a mold for electromagnetic heating, pressurizing by sealing and fixing the surroundings and pressurizing the upper part, the pressure is controlled at 5MPa, the electromagnetic heating temperature is controlled at 140°C, and the holding time is 8-10 seconds. Obtain the curb stone body.

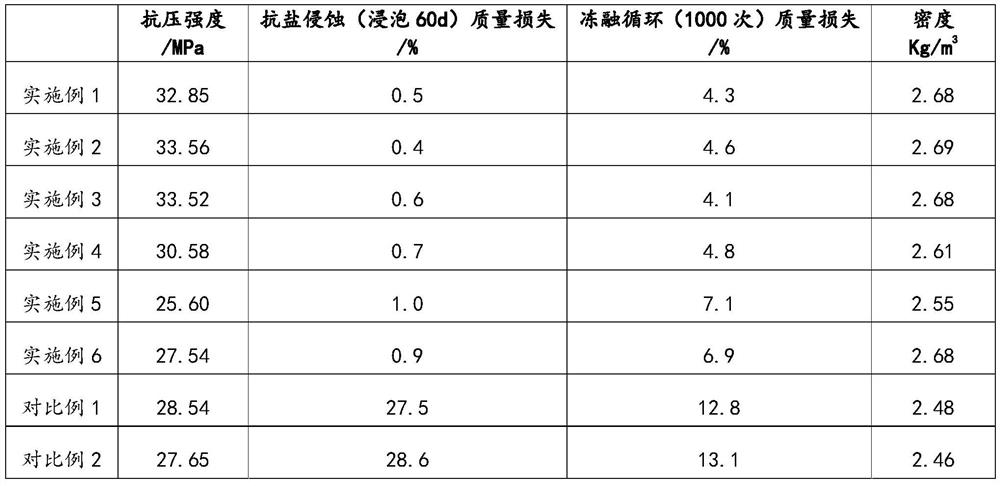

[0053] Using super-hydrophobic cement slurry to plaster the obtained curb body to obtain curb stones, the properties of curb stones are shown in Table 1.

[0...

Embodiment 3

[0056] A kind of curb stone prepared by using pavement recycled materials, which is made of the following components:

[0057] The mass ratio of RAP material is: 0-5mm: 55 parts, 5-12mm: 25 parts, 12-18mm: 15 parts, 18-30mm: 5 parts; Iron powder, 80-100 mesh; the amount of rock asphalt powder accounts for 3.5wt.% of the RAP material, and the particle size is 100-200 mesh.

[0058] The preparation steps include: putting the above materials into a mold for electromagnetic heating, pressurizing by sealing and fixing the surroundings and pressurizing the upper part, the pressure is controlled at 3MPa, the electromagnetic heating temperature is controlled at 160°C, and the holding time is 7 seconds to obtain curbstones body.

[0059] Using super-hydrophobic cement slurry to plaster the obtained curb body to obtain curb stones, the properties of curb stones are shown in Table 1.

[0060] The weight composition of the above-mentioned super-hydrophobic cement paste is: 100 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com