Method and system for preparing trifluoroacetic acid by hydrolyzing trifluoroacetyl chloride

A technology of trifluoroacetyl chloride and trifluoroacetic acid is applied in the preparation of acyl halide, separation/purification of carboxylic acid compounds, organic chemistry and other directions, which can solve the problems of high production cost, small production capacity, low hydrolysis efficiency, etc., and achieve energy saving , The effect of reducing equipment investment and improving hydrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

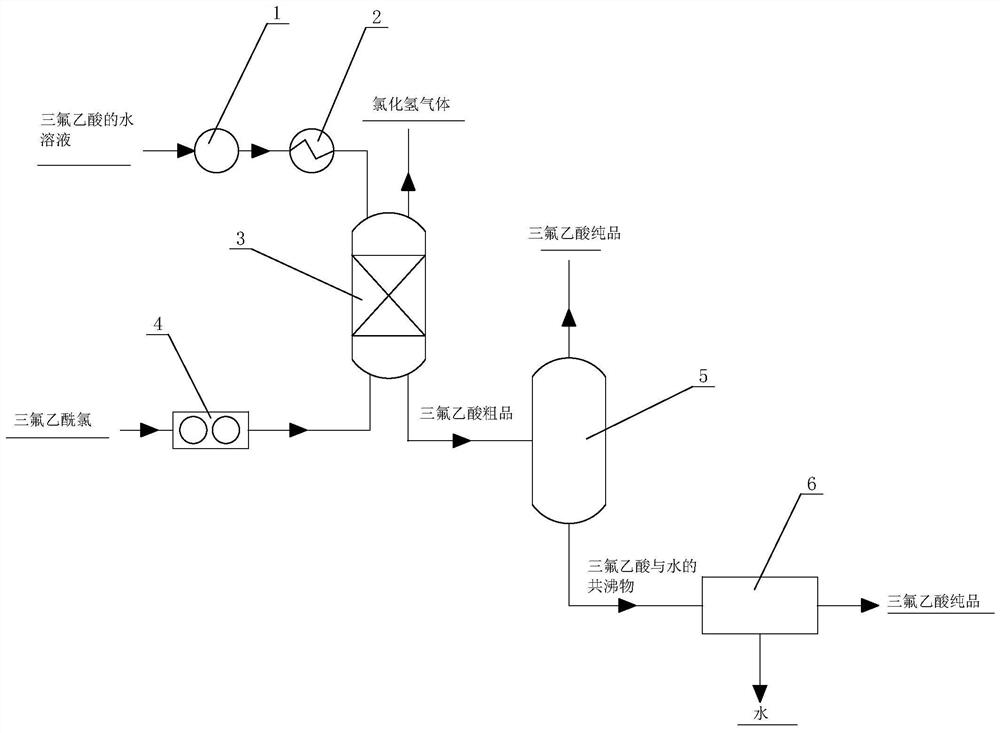

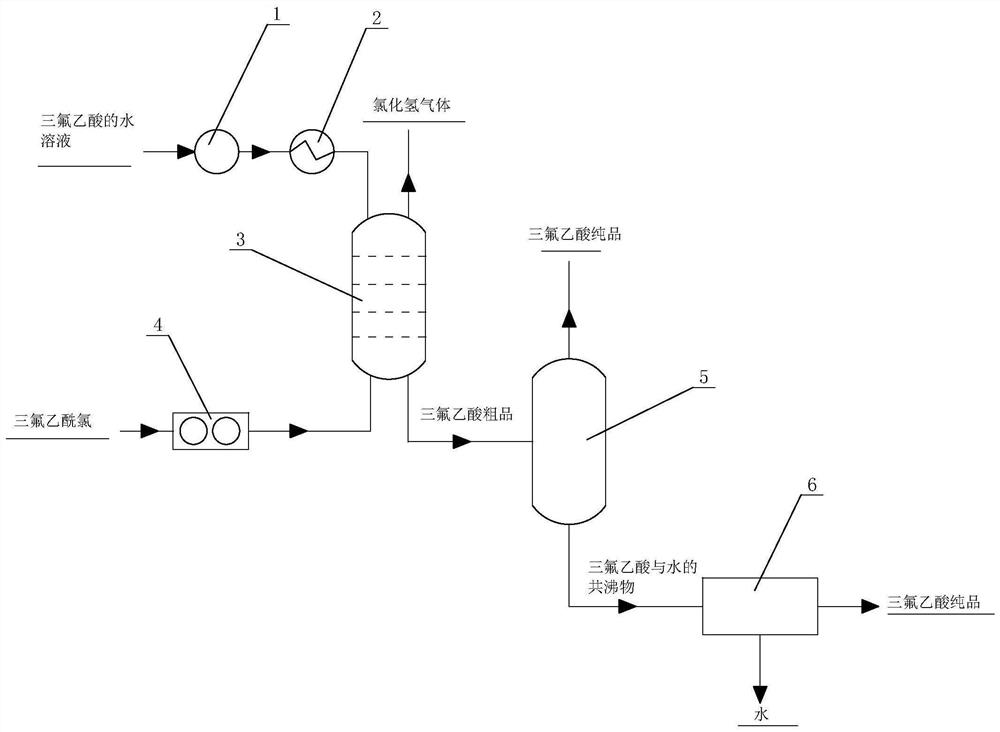

Embodiment 1

[0052] 1325kg / h of trifluoroacetyl chloride enters from the bottom of the packed hydrolysis tower, and 190kg / h of 5% trifluoroacetic acid aqueous solution is preheated to 30°C and then enters from the top of the packed hydrolysis tower, both of which are carried out in the packed hydrolysis tower Fully contacted, the hydrogen chloride gas produced by the hydrolysis reaction is discharged from the top of the packed hydrolysis tower, and the crude trifluoroacetic acid produced by the hydrolysis reaction enters the rectification tower 5 for distillation and purification. The temperature at the top of rectification tower 5 is 70°C to 90°C, and the pure product of trifluoroacetic acid with a purity >99.5% is obtained at the top of rectification tower 5, and the temperature at the bottom of rectification tower 5 is 100°C to 120°C, and the bottom of rectification tower 5 is obtained The azeotrope of trifluoroacetic acid and water enters the pervaporation membrane water removal device ...

Embodiment 2

[0054] 1325kg / h of trifluoroacetyl chloride enters from the bottom of the packed hydrolysis tower, and 380kg / h of 5% trifluoroacetic acid aqueous solution is preheated to 50°C and then enters from the top of the packed hydrolysis tower, both of which are carried out in the packed hydrolysis tower Full contact, the hydrogen chloride gas produced by the hydrolysis reaction is discharged from the top of the packed hydrolysis tower, and the crude trifluoroacetic acid produced by the hydrolysis reaction enters the rectification tower 5 for distillation and purification. Pure trifluoroacetic acid with a purity >99.5% is obtained at the top, the temperature at the bottom of rectification tower 5 is 100°C to 120°C, and the azeotrope of trifluoroacetic acid and water obtained at the bottom of rectification tower 5 enters the pervaporation membrane water removal device 6 , the pervaporation membrane removes the moisture in the azeotrope of trifluoroacetic acid and water to obtain pure tr...

Embodiment 3

[0056] 1325kg / h of trifluoroacetyl chloride enters from the bottom of the plate hydrolysis tower, and 380kg / h of 5% trifluoroacetic acid aqueous solution is preheated to 60°C and enters from the top of the plate hydrolysis tower. The two are carried out in the plate hydrolysis tower Fully contact, the hydrogen chloride gas produced by the hydrolysis reaction is discharged from the top of the plate hydrolysis tower, and the crude product of trifluoroacetic acid enters the rectification tower 5 for distillation and purification. >99.5% pure trifluoroacetic acid, the temperature at the bottom of the rectification tower 5 is 100°C to 120°C, and the azeotrope of trifluoroacetic acid and water obtained at the bottom of the rectification tower 5 enters the pervaporation membrane water removal device 6 for pervaporation The membrane removes the moisture in the azeotrope of trifluoroacetic acid and water to obtain pure trifluoroacetic acid with a purity >99.5%, and the yield of trifluor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com