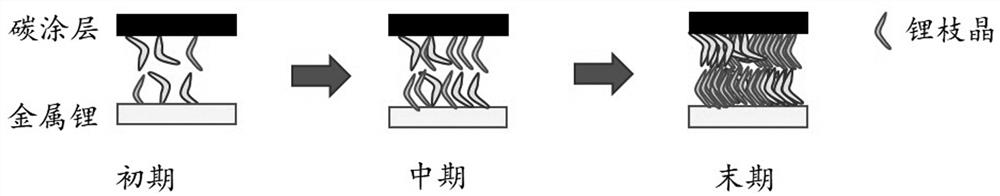

A solid-state battery with controlled lithium dendrite growth

A solid-state battery and lithium dendrite technology, applied in the field of solid-state batteries based on this electrolyte, can solve problems such as potential safety hazards and easy triggering of short-circuit accidents, and achieve the effect of improving interface impedance and improving conduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

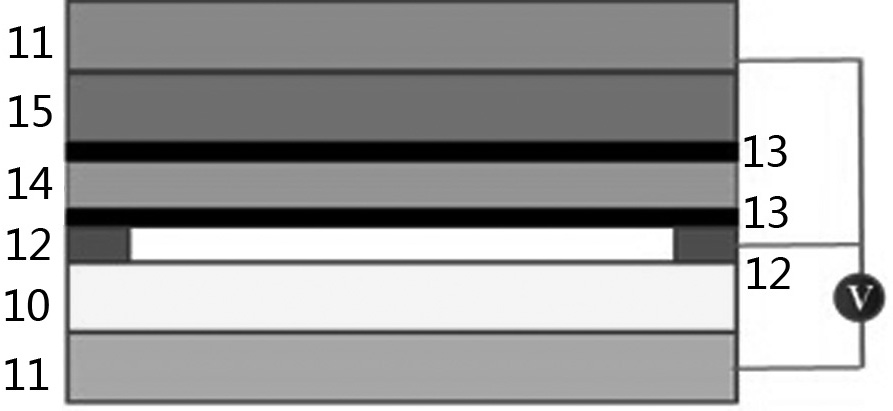

Method used

Image

Examples

Embodiment 1

[0023] This example prepares LiFePO 4 The material is the positive electrode, metal lithium is the negative electrode, Li 0.34 La 0.51 TiO 2.94 Solid-state button batteries with inorganic electrolytes. The preparation of the solid electrolyte and the carbon material coating and bonding process are as follows:

[0024] 1) Put an appropriate amount of carbon nanotubes into concentrated sulfuric acid solution, ultrasonicate for 6 h, and keep the acidification temperature at 55 °C.

[0025] 2) The carbon nanotubes treated with concentrated sulfuric acid are collected by filtration, and washed repeatedly with deionized water until the pH value of the last washing solution is in the range of 6-7.

[0026] 3) Weigh an appropriate amount of carbon nanotubes and polyvinylidene fluoride (PVDF) according to the mass ratio of 8:1, then add an appropriate amount of N-methylpyrrolidone (NMP) solvent, and use a homogenizer to fully stir the slurry for 30 minutes until the slurry No grai...

Embodiment 2

[0031] Prepared with Li[Ni 0.8 co 0.1 mn 0.1 ]O 2 The ternary material is the positive electrode, the metal lithium is the negative electrode, and the solid-state pouch battery with polyethylene oxide (PEO)-based polymer electrolyte. The preparation of the solid electrolyte and the carbon material coating and bonding process are as follows:

[0032] 1) Put an appropriate amount of modified graphene into concentrated nitric acid solution, ultrasonicate for 6 h, and keep the acidification temperature at 55 °C.

[0033] 2) The modified graphene treated with concentrated nitric acid is collected by filtration, and washed repeatedly with deionized water until the pH value of the last washing solution is in the range of 6-7.

[0034] 3) Weigh an appropriate amount of modified graphene and polyvinylidene fluoride (PVDF) according to the mass ratio of 8:1, then add an appropriate amount of N-methylpyrrolidone (NMP) solvent, and use a homogenizer to fully stir the slurry for 30 min...

Embodiment 3

[0039] Prepared with LiFePO 4 The material is the positive electrode, the metal lithium is the negative electrode, and the pouch battery of the organic-inorganic composite electrolyte. The preparation of the solid electrolyte and the carbon material coating and bonding process are as follows:

[0040] 1) Put an appropriate amount of carbon nanofibers into concentrated sulfuric acid solution, ultrasonicate for 6 h, and keep the acidification temperature at 55 °C.

[0041] 2) The carbon nanofibers treated with concentrated sulfuric acid are collected by filtration, and washed repeatedly with deionized water until the pH value of the last washing solution is in the range of 6-7.

[0042] 3) Weigh an appropriate amount of carbon nanofibers and polyvinylidene fluoride (PVDF) according to the mass ratio of 8:1, then add an appropriate amount of N-methylpyrrolidone (NMP) solvent, and use a homogenizer to fully stir the slurry for 30 minutes until the slurry No graininess and blends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com