Water plant alum adding control method based on feedforward-feedback composite control

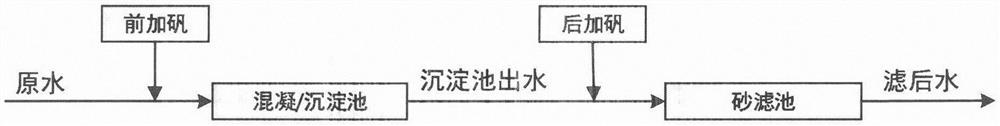

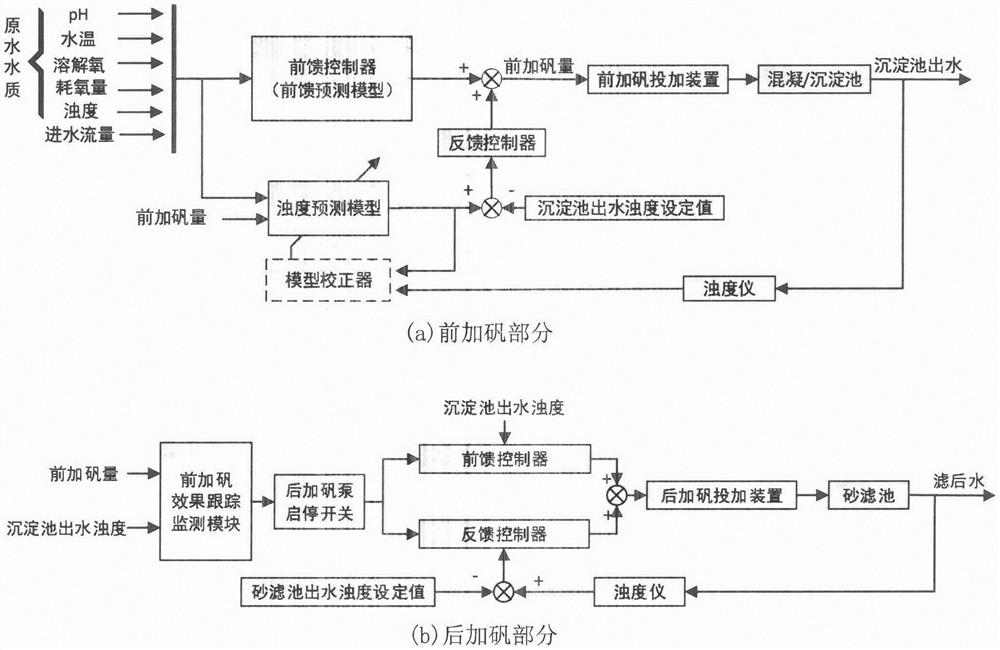

A technology for water plants and raw water, which is used in adaptive control, general control system, water treatment parameter control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The technical scheme of the present invention will be described in detail below in conjunction with the actual on-line test at the Baiyang Bay Waterworks of Suzhou Tap Water Co., Ltd.:

[0064] (1) According to adding alum before adding alum feed-forward-feedback composite control method to calculate before adding alum amount, concrete steps are as follows:

[0065] The first step is to obtain the real-time pre-feed-forward alum addition amount

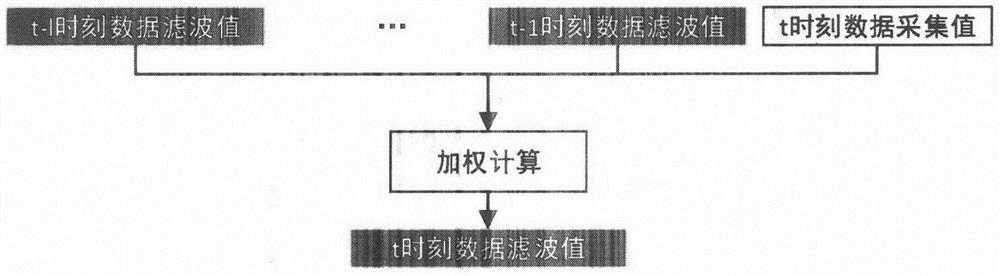

[0066] Step 1, in the production and operation database of the water plant, screen out the raw water quality indicators (pH, water temperature, dissolved oxygen, oxygen consumption , turbidity), influent flow, and the historical data of the amount of alum added before, and perform data filtering processing, and divide the obtained historical data samples into two parts: training set and test set;

[0067] Step 2. Taking the raw water quality indicators (pH, water temperature, dissolved oxygen, oxygen consumption, turbidity) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com