Resin-based laminate with excellent water resistance and preparation method thereof

A resin and base layer technology, applied in the field of composite material preparation, can solve the problem of no long-term use requirements of composite materials, and achieve the effect of good low water absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] Preferably, the preparation method further includes: pre-soaking the basalt fiber cloth with the resin glue solution as described in any of the aforementioned embodiments or the resin glue solution prepared by the method for preparing the resin glue solution as described in any of the aforementioned implementations.

[0059] In some embodiments, the preparation method further includes pre-curing the basalt fiber cloth impregnated with resin glue into a prepreg; the pre-curing conditions are: oven temperature 160°C-170°C, speed 6-8 meters / min.

Embodiment 1

[0062] This embodiment provides a resin-based laminate with excellent water resistance, and its preparation method is as follows.

[0063] (1) resin glue

[0064] In parts by weight, the raw materials of resin glue include: 30 parts of isobutanol etherified melamine resin (molecular weight is 170), 45 parts of E44 bisphenol A glycidyl ether type epoxy resin (epoxy value is 0.44, epoxy resin Equivalent weight is 220), 3 parts of dimethylbenzylamine, 0.7 parts of UV light blocker, 25 parts of denatured alcohol and 15 parts of toluene.

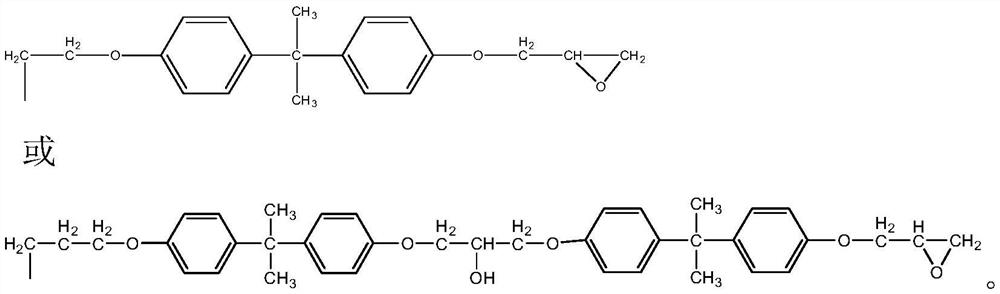

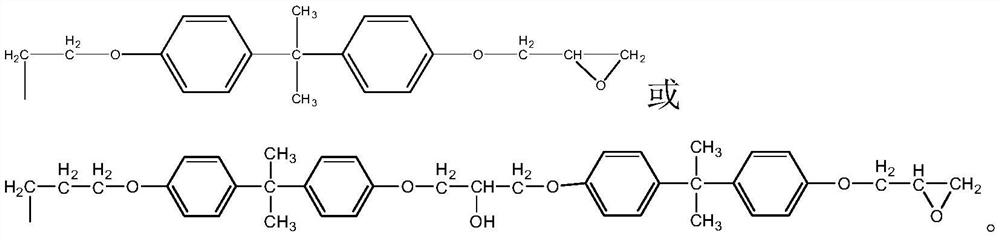

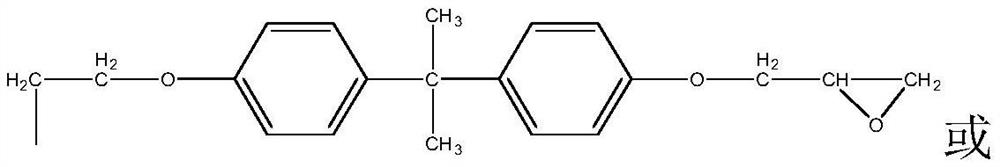

[0065] Weigh 100g of isobutanol etherified melamine resin and 150g of E44 bisphenol A glycidyl ether type epoxy resin into a three-necked flask with a stirrer and a condenser, stir and raise the temperature to 115°C to allow polymerization to occur, forming The prepolymer shown in Formula 1 was incubated for 50 minutes, and the reaction was completed.

[0066] Formula 1:

[0067] Wherein, n is selected from 1 to 5, and R is selected from:

...

Embodiment 2

[0076] This embodiment provides a resin-based laminate with excellent water resistance, the preparation method of which is roughly the same as that of Embodiment 1, with the difference that:

[0077] The mass ratio of the melamine resin to the epoxy resin is different, and in this embodiment, the mass ratio of the melamine resin to the epoxy resin is 1:1.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com