Environment-friendly high-efficiency nylon demoulding master batch and preparation method thereof

A high-efficiency, nylon-based technology, applied in the field of environmentally friendly and high-efficiency nylon release masterbatch and its preparation, can solve the problems of short molding cycle, masterbatch not reaching the effect, no demoulding, etc., to increase the crystallization rate, shorten the molding cycle, The effect of improving the release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

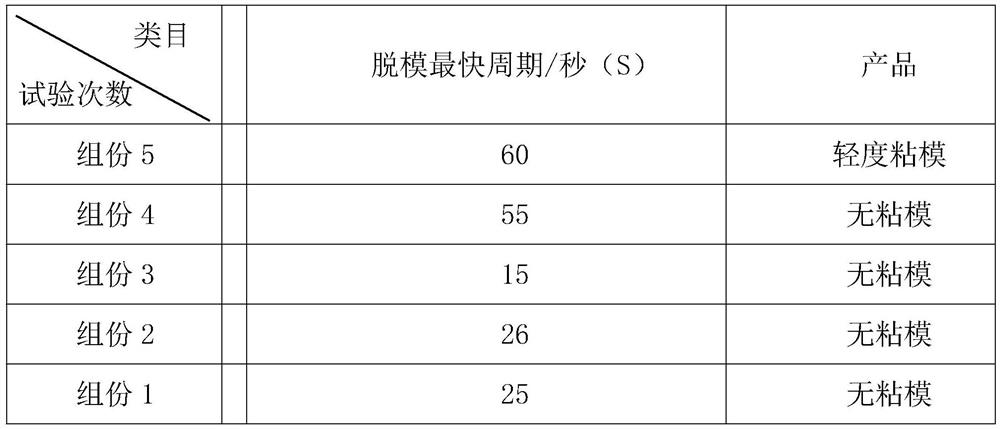

Examples

Embodiment 1

[0020] In the embodiment of the present invention, an environment-friendly and high-efficiency nylon mold release masterbatch includes, in parts by mass: 60 parts of nylon slices, 10 parts of nano-silica, 5 parts of EBS, and 0.2 parts of antioxidant;

[0021] The relative viscosity of the nylon chips is 2.5;

[0022] A method for preparing an environmentally friendly and efficient nylon release masterbatch, comprising the following steps: step 1, weighing ingredients according to the proportion of each raw material, and mixing them uniformly to obtain a mixture; step 2, mixing the mixture in step 1 through parallel double Plasticized by screw extruder, sheared by screw, then water-cooled, pelletized, and vacuum-dried to obtain environmentally friendly and efficient nylon release masterbatch;

[0023] In the step 1, each raw material is mixed in a vertical mixer, the rotating speed of the mixer is 60r / min, and the mixing time is 10-20min, and the temperature control of the barr...

Embodiment 2

[0025] An environment-friendly and high-efficiency nylon mold release masterbatch, comprising: nylon chips: 80 parts, nano-silica: 20 parts, EBS: 10 parts, antioxidant: 0.5 parts;

[0026] The relative viscosity of the nylon chips is 2.5;

[0027] A method for preparing an environmentally friendly and efficient nylon release masterbatch, comprising the following steps: step 1, weighing ingredients according to the proportion of each raw material, and mixing them uniformly to obtain a mixture; step 2, mixing the mixture in step 1 through parallel double Plasticized by screw extruder, sheared by screw, then water-cooled, pelletized, and vacuum-dried to obtain environmentally friendly and efficient nylon release masterbatch;

[0028] In the step 1, each raw material is mixed in a vertical mixer, the rotating speed of the mixer is 60r / min, and the mixing time is 10-20min, and the temperature control of the barrel of the parallel twin-screw extruder is as follows: first, The secon...

Embodiment 3

[0030] An environment-friendly and high-efficiency nylon mold release masterbatch, comprising: 55 parts of nylon slices, 15 parts of nano-silica, 6 parts of EBS, and 0.3 parts of antioxidant in terms of parts by mass;

[0031] The relative viscosity of the nylon chips is 2.5;

[0032] A method for preparing an environmentally friendly and efficient nylon release masterbatch, comprising the following steps: step 1, weighing ingredients according to the proportion of each raw material, and mixing them uniformly to obtain a mixture; step 2, mixing the mixture in step 1 through parallel double Plasticized by screw extruder, sheared by screw, then water-cooled, pelletized, and vacuum-dried to obtain environmentally friendly and efficient nylon release masterbatch;

[0033] In the step 1, each raw material is mixed in a vertical mixer, the rotating speed of the mixer is 60r / min, and the mixing time is 10-20min, and the temperature control of the barrel of the parallel twin-screw ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com