Multifunctional inspection device for circuit board cleaning machine

A technology for inspection devices and circuit boards, which is applied in the cleaning/polishing of conductive patterns, printed circuits, and printed circuit manufacturing, etc. It can solve the problems of inconvenient inspection, inconvenient adjustment of limit conveying, inconvenient drying, etc., and achieve the effect of increasing the detection direction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

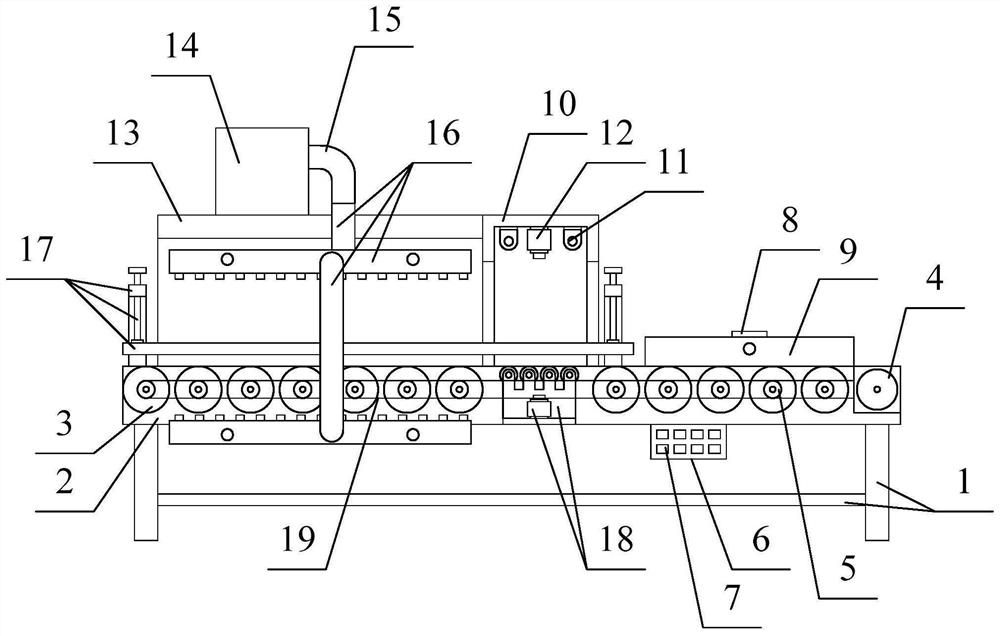

[0030] The present invention will be further described below in conjunction with accompanying drawing:

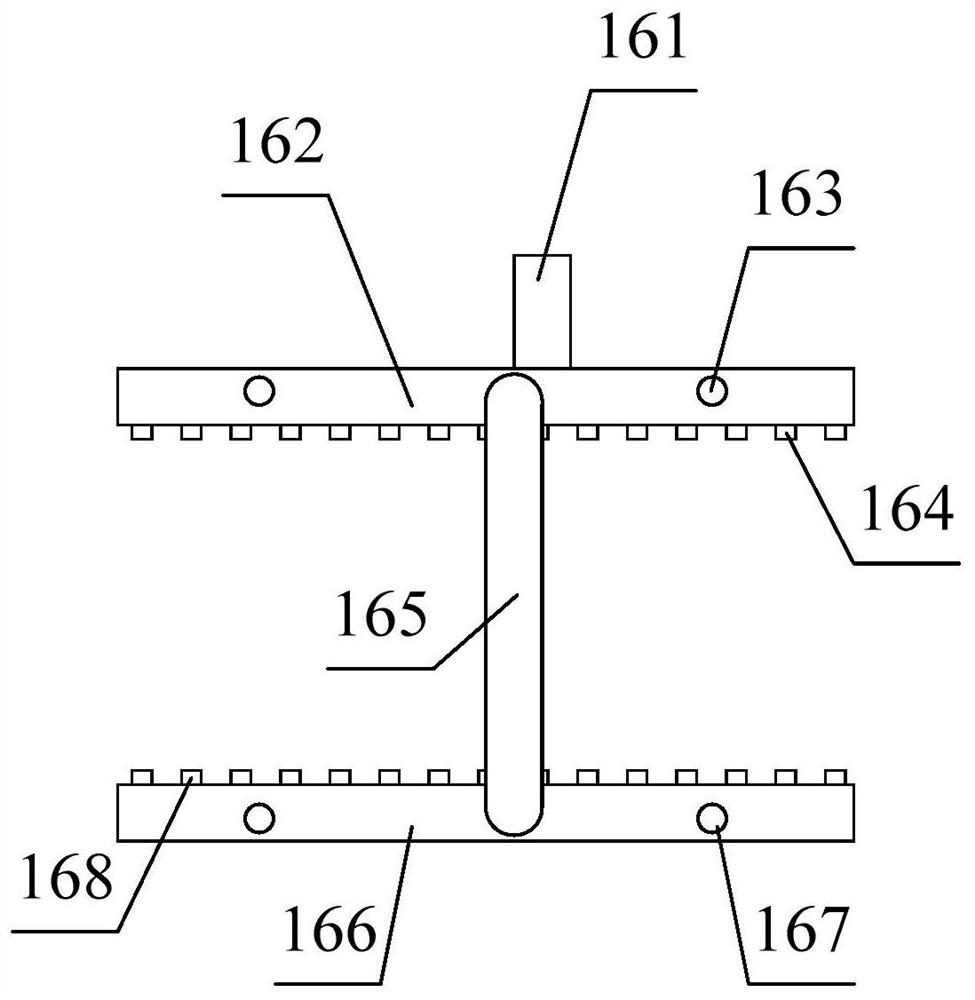

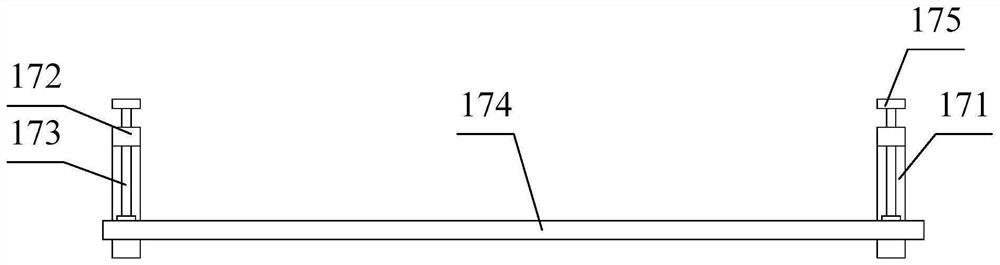

[0031] as attached figure 1 And attached figure 2As shown, a multifunctional circuit board cleaning machine inspection device according to the present invention includes a support frame 1, a support plate 2, a conveying roller 3, a drive motor 4, a double-row sprocket 5, a PLC 6, a drive switch 7, and a drive switch 7. Cylinder 8, push plate 9, installation shell 10, LED light 11, upper camera 12, socket shell 13, air pump 14, connecting pipe 15, multi-directional drying and heating box structure 16, adjustable limit frame structure 17, support detection frame structure 18 and chain 19, the support plate 2 is welded to the front and rear parts of the upper end of the support frame 1 respectively; the conveying roller 3 is installed between the support plate 2 and the support plate 2 through bearings; the drive motor 4 The bolt is installed on the right side of the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com