A transmission steering arm forging process

A steering arm and process technology, applied in the field of forging, can solve the problems of low guiding precision of hammer forging equipment, increase the cost of production process, low processing efficiency, etc., so as to improve material utilization rate and forming rate, improve material utilization rate, and improve production Efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

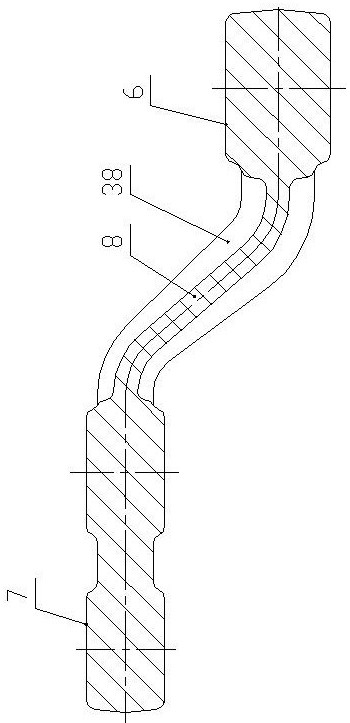

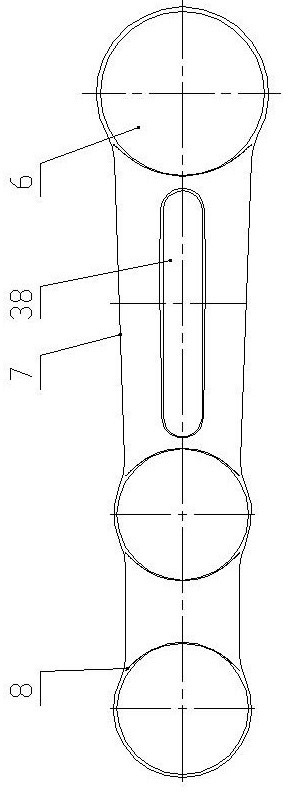

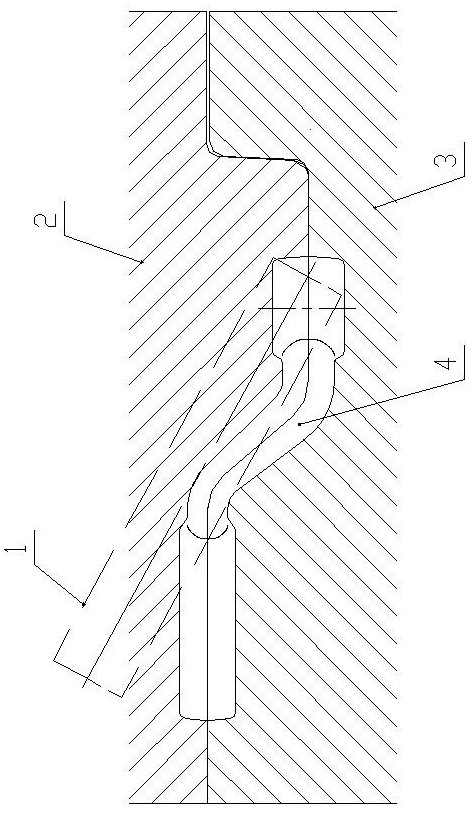

[0052] Such as Figure 4-Figure 7 As shown, a transmission steering arm forging process of the present invention comprises the following steps:

[0053] (1) cutting;

[0054] (2) Heating;

[0055] (3) Blank bending;

[0056] (4) Pre- and final forging;

[0057] (5) trimming;

[0058] (6) Calibration;

[0059] (7) shot blasting;

[0060] (8) Normalizing.

[0061] Step (1) The specific process of blanking is as follows: the raw material is 40Cr steel with a diameter of 60mm, and the blanking weight is 7.84±0.02Kg. Use the P70B high-speed circular saw to saw the blank; the speed of the high-speed circular saw is 120-130r / s, the tooth cutting thickness is 0.065-0.07mm, the blanking time of a single blank is 12s, and the blanking length tolerance is ±0.05mm , End surface horseshoe degree ≤ 0.1mm.

[0062] The specific heating process of step (2) is: use a 1000KW medium frequency induction heating furnace to heat the billet 1, the heating temperature range is 1100-1200°C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com