RFID cigarette package box and manufacturing method

A production method and technology for packaging boxes, which are applied in box production operations, packaging, tobacco and other directions, can solve the problems of inability to communicate and identify electronic labels on cigarette packs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The manufacturing method of the RFID tobacco packaging box of the present invention comprises the following steps:

[0054] (1) Production of lining paper for cigarette packs:

[0055] First, use a dry coater to coat the transfer coating on the PET film. The transfer coating can be polyvinyl butyral, so as to facilitate the transfer of the aluminized film.

[0056] On the PET film, use a vacuum aluminum coating machine to heat and volatilize the aluminum wire and evaporate the aluminum foil in a vacuum state to form an aluminum coating;

[0057] On the gravure printing machine, the aluminum plating layer is printed with protective ink, and the opening part of the feeder ring is exposed, and the acid and alkali etching process is used. The acid etching process usually uses 35-37% hydrochloric acid; if the alkali etching process is used, usually 25% is used. - 30% sodium hydroxide solution. After positioning and washing the aluminum, the protective ink is washed off, wa...

Embodiment 2

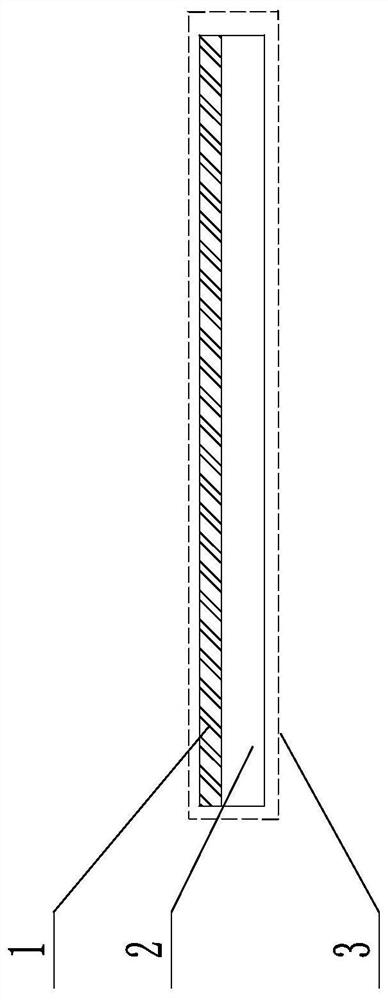

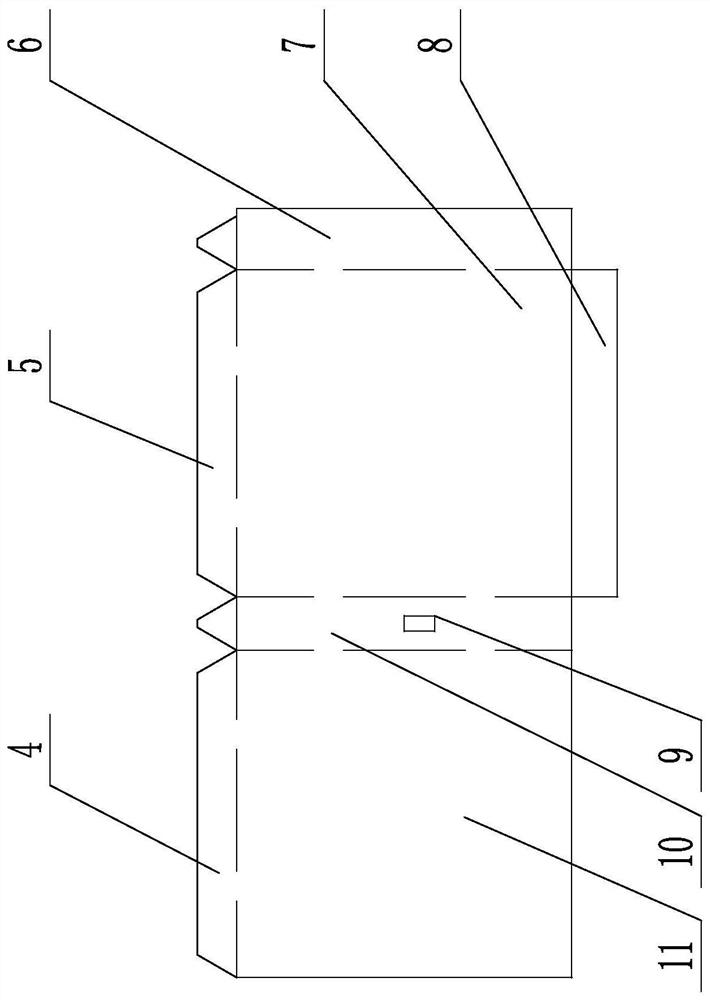

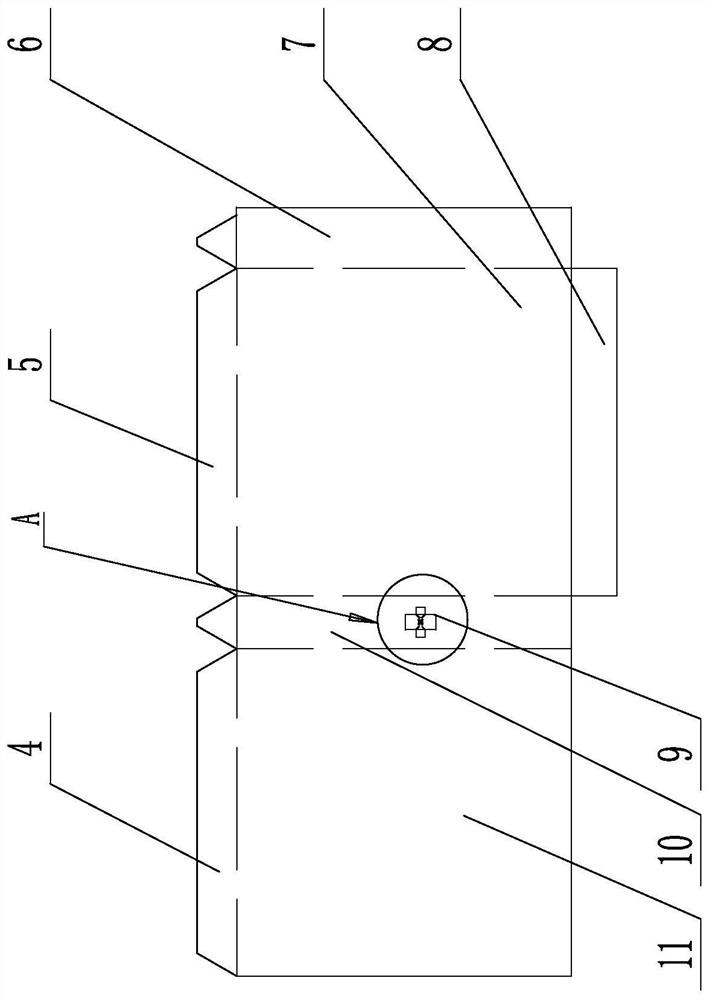

[0067] Such as Figure 1 to Figure 6 Shown, the manufacture method of RFID tobacco packaging box of the present invention, comprises the following steps:

[0068] Main materials: Cigarette pack lining base paper, about 65 g / square meter, aluminum wire, special oil spray for aluminum plating, chip, 30-50 micron PET composite aluminum film, conductive adhesive.

[0069] (1) Aluminizing process of inner lining paper of cigarette packs:

[0070] Use the base paper lining the cigarette pack as the backing paper layer. First, set the oil injection position, shape and size of the vacuum aluminum plating machine. After the aluminum plating starts, spray oil through positioning on the base paper lining the cigarette pack to control this area from being able to adhere to the plating. The aluminum film is formed to form the opening of the feed ring, and the aluminum is vacuum-coated on the base paper for the inner lining of the cigarette pack, cooled and rolled, and the inner paper for ...

Embodiment 3

[0079] Such as Figure 1 to Figure 6 Shown, the manufacture method of RFID tobacco packaging box of the present invention, comprises the following steps:

[0080] Prepare the main materials: pure aluminum foil, about 75 grams per square meter, chip, 30-50 micron PET composite aluminum film, conductive adhesive.

[0081] (1) Manufacturing process of aluminum foil lined with cigarette packs:

[0082] According to the design requirements, the feeder ring opening die-cutter is made, and on the rotary die-cutting machine, the roll-shaped pure aluminum foil is positioned and die-cut to form the feeder ring opening aluminum foil with equal adjacent distances and the same shape and size, and the tobacco-lined aluminum foil is obtained. , that is, a cigarette pack lining paper with only one layer of pure aluminum foil.

[0083] (2) Production of STRAP straps: using reverse chip technology, on the pre-etched STRAP antenna, use conductive adhesive to bind the chip, and apply self-adhes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com