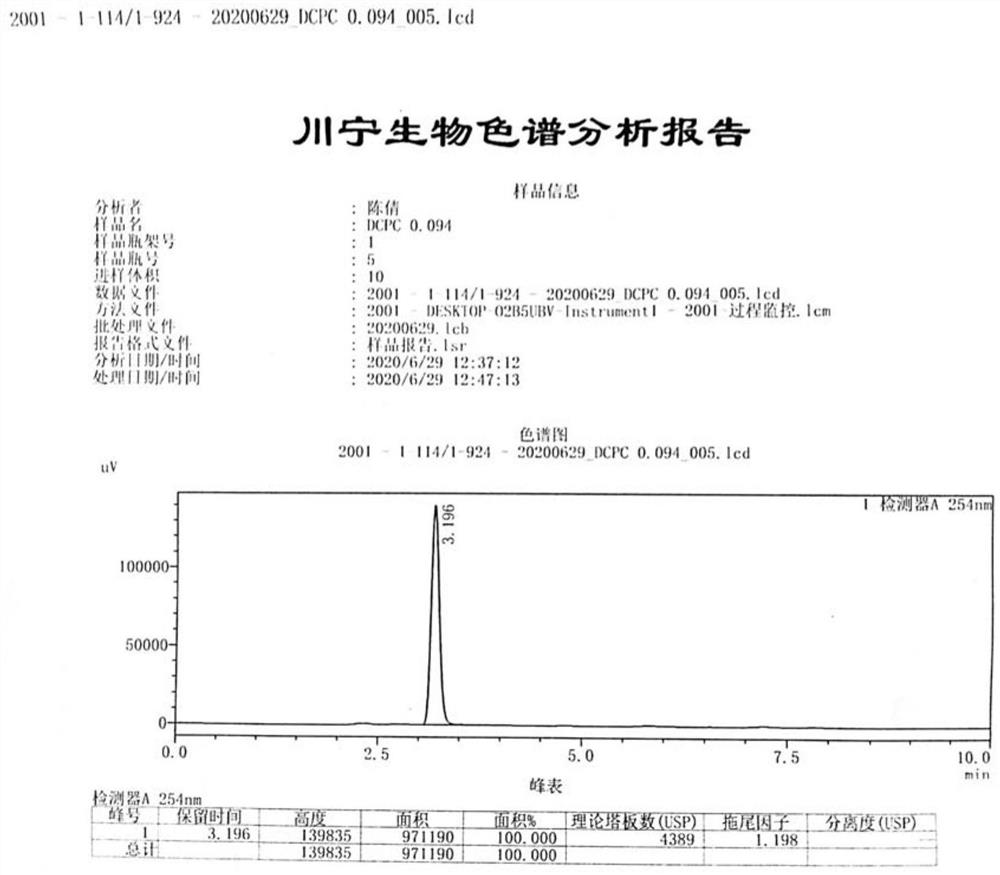

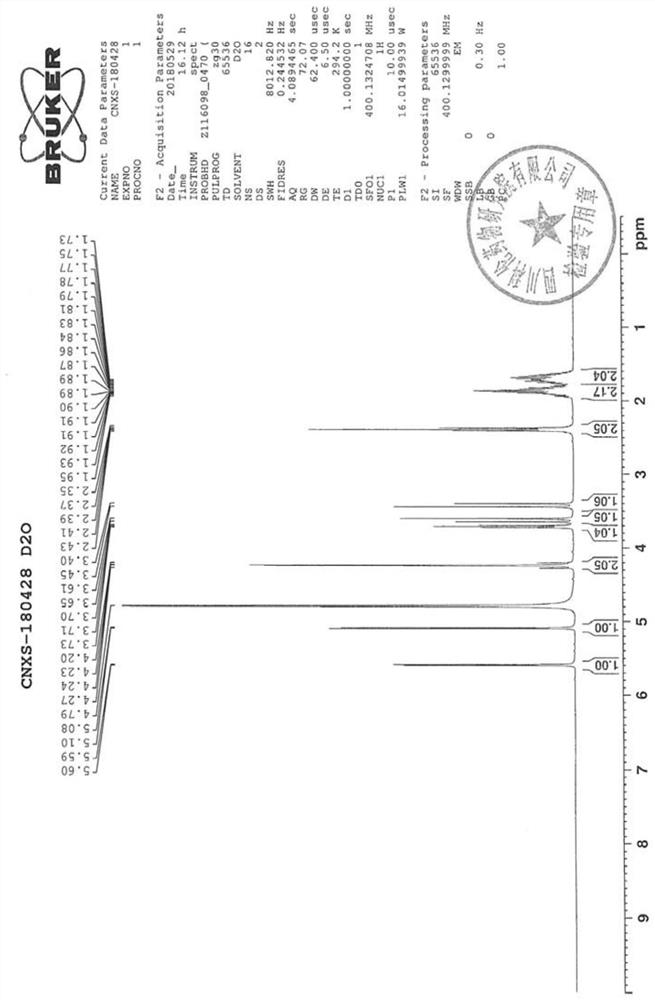

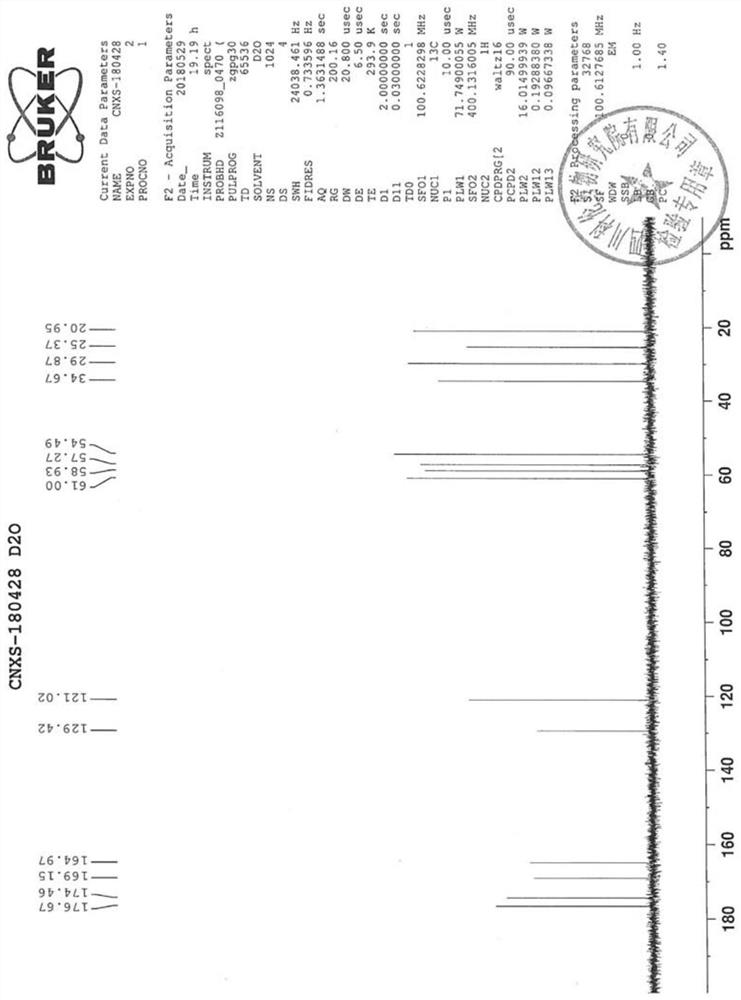

Preparation method of high-purity 3-deacetylcephalosporin C sodium salt

An acetyl head, cephalosporin technology, applied in the direction of organic chemistry, etc., can solve the problems affecting the quality, low purity and complex process of CPC sodium salt or DAOC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 The preparation method of 3-deacetyl cephalosporin C sodium salt of the present invention

[0026] (1) Dissolution: Take 60ml of deionized water, lower the temperature to 8-10°C, and slowly add 8.0g of CPC sodium salt under stirring condition, stir and dissolve until clear. Add 0.1 g of activated carbon, stir to decolorize, filter through a 0.45 μm aqueous membrane, and collect the filtrate to obtain a CPC solution;

[0027] (2) Cracking: warming up the dissolving solution in step (1) to 12°C, adding immobilized deacetylesterase to it under stirring condition, controlling the reaction temperature at 12-15°C, slowly adding ammonia water with a weight percentage concentration of 5% , control the pH8-8.5 to carry out the cleavage reaction. Stirring speed control 350r / min. The pH does not drop within five minutes as the end point of the reaction. Then use a sand core funnel to filter, collect the filtrate to obtain DCPC hydrolyzate. Keep the enzymes ready f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com