High-strength transparent polypropylene and preparation method thereof

A transparent polypropylene and high-strength technology, applied in the field of polymers, can solve the problems of small strength improvement of polypropylene materials and great influence on the transparency of polypropylene.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

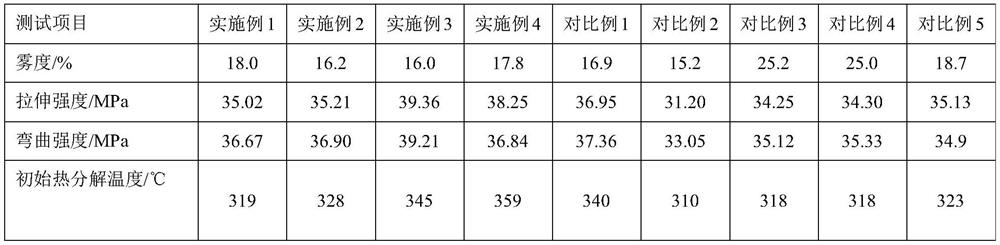

Examples

Embodiment 1

[0050] Preparation of polypropylene imine modified nano-silica:

[0051] Activate 2g of nano-silica in 10g of nitric acid solution with a concentration of 1mol / L, the activation temperature is 60°C, and the activation time is 6h; then, in a nitrogen atmosphere, add 150ml of toluene, 5ml of 3-chloropropyltriethoxysilane and 2g of activated nano-silica was reacted at 100°C for 48h, the solid was separated, and dried at 50°C for 12h; finally, the dried solid was added to 60wt% polypropyleneimine aqueous solution, and then 100ml of methanol was added, and dried at 60°C After reacting for 24 hours, polypropyleneimine-modified nano-silica was obtained.

[0052] Preparation of high-strength transparent polypropylene (parts by mass):

[0053] Weigh 100 parts of polypropylene, 0.1 part of bis-1,3,2,4 (4'-propylbenzylidene) 1-propyl sorbitol nucleating agent, 1 part of polypropylene imine modified nano-silica , 0.02 part of polypropylene grafted maleic anhydride, 0.1 part of antioxida...

Embodiment 2

[0056] Preparation of polypropylene imine modified nano-silica:

[0057] Activate 2g of nano-silica in 10g of nitric acid solution with a concentration of 0.5mol / L, the activation temperature is 50°C, and the activation time is 4h; then, in a nitrogen atmosphere, add 150ml of toluene and 5ml of 3-chloropropyltriethoxysilane React with 2g of activated nano-silica at 90°C for 24h, separate the solid, and dry at 50°C for 12h; finally, add the dried solid to 60wt% polypropyleneimine aqueous solution, add 100ml of methanol, and then dry at 30°C °C for 12 hours to obtain polypropyleneimine-modified nano-silica.

[0058] Preparation of high-strength transparent polypropylene (parts by mass):

[0059] Weigh 100 parts of polypropylene, 0.2 parts of bis-1,3,2,4 (4'-propylbenzylidene) 1-propyl sorbitol nucleating agent, 2 parts of polypropylene imine modified nano-silica , 0.02 part of polypropylene grafted maleic anhydride, 0.2 part of antioxidant;

[0060] Put each raw material in a...

Embodiment 3

[0062] Preparation of polypropylene imine modified nano-silica:

[0063] Activate 2g of nano-silica in 10g of nitric acid solution with a concentration of 2mol / L, the activation temperature is 80°C, and the activation time is 7h; then, in a nitrogen atmosphere, add 150ml of toluene, 5ml of 3-chloropropyltriethoxysilane and 2g of activated nano-silica was reacted at 120°C for 60h, the solid was separated, and dried at 50°C for 12h; finally, the dried solid was added to 60wt% polypropyleneimine aqueous solution, 100ml of methanol was added, and then dried at 60°C After reacting for 36 hours, polypropyleneimine-modified nano-silica was obtained.

[0064] Preparation of high-strength transparent polypropylene (parts by mass):

[0065] Weigh 100 parts of polypropylene, 0.2 parts of bis-1,3,2,4 (4'-propylbenzylidene) 1-propyl sorbitol nucleating agent, 3 parts of polypropylene imine modified nano-silica , 0.06 part of polypropylene grafted maleic anhydride, 0.3 part of antioxidant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com