Aluminum foil for 1070 high-performance lithium ion battery and preparation method of aluminum foil

A lithium-ion battery, high-performance technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of low strength and elongation of 1070 aluminum alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

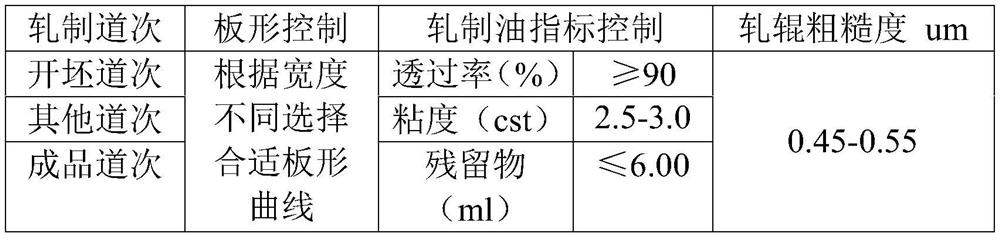

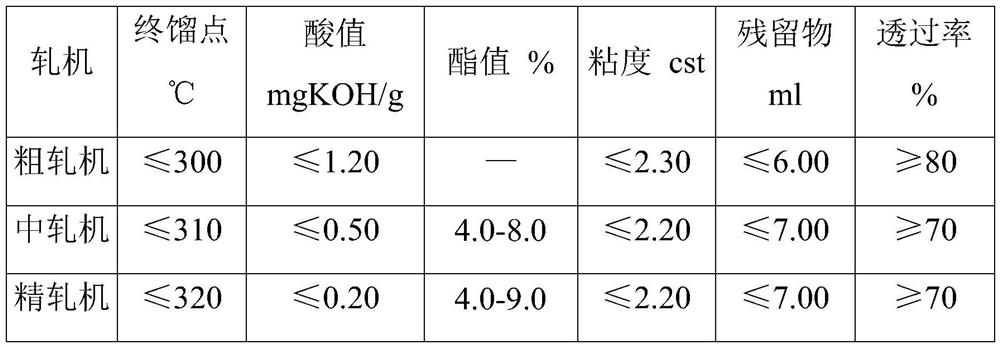

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the above-mentioned 1070 high-performance aluminum foil for lithium-ion batteries comprises the following steps:

[0036] S1. Ingredients, weigh the corresponding raw materials according to the composition design. The raw materials include scraps of the 1070 aluminum alloy with a mass percentage not higher than 15%, and the remaining aluminum is pure aluminum ingots. The use of the aluminum alloy scrap can realize the reuse of the scrap and reduce the material cost.

[0037] S2. Smelting: Put the prepared raw materials into the melting furnace for melting, and refine the aluminum alloy liquid after the raw materials are completely melted; add the Al-Ti intermediate alloy into the melting furnace during the melting. During smelting, the charge should be kept clean, and the quality of the melt should be good to meet the production requirements of aluminum foil. The hydrogen content is ≤0.12ml / 100Al, the refining temperature is ≥730°C, the refin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com