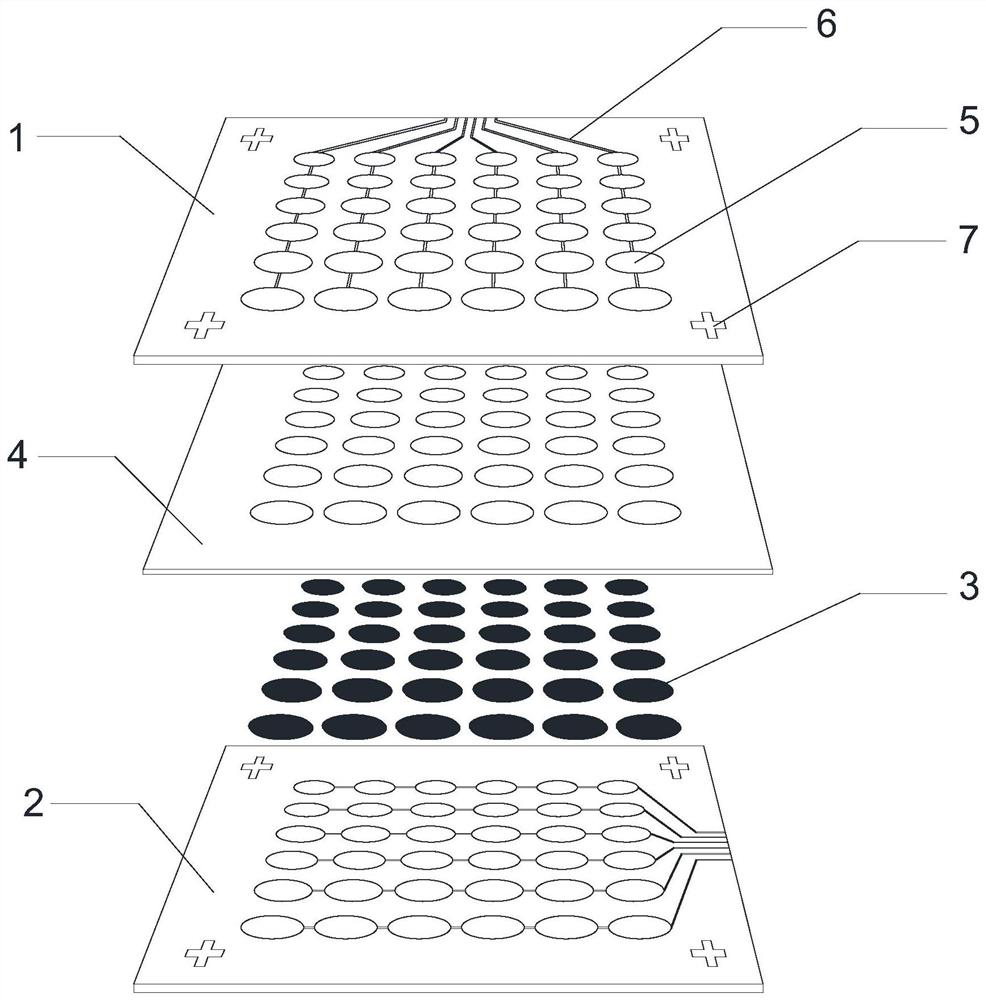

Sandwich type large-area high-density flexible array sensor and preparation method thereof

A sandwich-type, flexible array technology, applied in the field of sensors, can solve the problems of low efficiency, high production cost, low material utilization rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

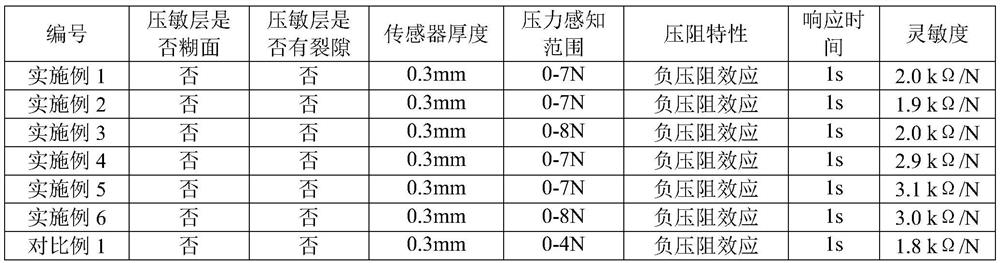

Embodiment 1

[0047] Preparation of polar plates: Use 420-mesh steel mesh plate to print Youtexin ID01 type conductive silver paste on two PET substrates by screen printing process, and form corresponding array electrodes and wires on the two PET substrates , after printing, place it in a blast oven and dry it at 120°C for 40 minutes to prepare the upper and lower plates;

[0048] Preparation of pressure-sensitive composite materials: 20g Ketjen black ECP600JD, 5g carbon nanotubes, 5g nano-SiO 2 and 10g of 2% silane coupling agent Si-69, added to 85g of naphtha, stirred and ultrasonically dispersed for 30 minutes to form a dispersion, added 350g of room temperature vulcanized silicone rubber Dow Corning 184 to the dispersion, stirred magnetically at room temperature for 3 hours to form a viscous Mixed solution, place the mixed solution in a vacuum drying oven at 40°C to dry for 20 minutes, remove air bubbles and incompletely volatilized naphtha, and obtain an uncured pressure-sensitive comp...

Embodiment 2

[0052] Preparation of polar plates: Use 300-mesh polyester screen to print Youtexin ID01 type conductive silver paste on two PET substrates by screen printing process, and form corresponding array electrodes and electrodes on the two PET substrates. Lead wires, after printing, place them in a blast oven and dry them at 140°C for 60 minutes to make upper and lower plates;

[0053] Preparation of pressure-sensitive composite materials: 75g Ketjen carbon black ECP600JD, 25g carbon nanotubes, 20g nano-SiO 2 And 40g of 2% silane coupling agent Si-69, add 25g of n-hexane, 65g of naphtha and 25g of absolute ethanol mixed solution, after stirring, ultrasonically disperse for 60min to form a dispersion, add 450g of room temperature vulcanized silicon to the dispersion Rubber Dow Corning 184, stirred magnetically at room temperature for 8 hours to form a viscous mixture, and dried the mixture in a vacuum drying oven at 100°C for 30 minutes to remove air bubbles and incompletely volatili...

Embodiment 3

[0057] Preparation of polar plates: Use 400-mesh polyester screen to print Youtexin ID01 conductive silver paste on two PET substrates by screen printing process, and form corresponding array electrodes and electrodes on the two PET substrates. Lead wires, after printing, place them in a blast oven and dry them at 130°C for 50 minutes to make upper and lower plates;

[0058] Preparation of pressure-sensitive composite materials: 50g Ketjen carbon black ECP600JD, 10g carbon nanotubes, 15g nano-SiO 2 And 30g of 2% silane coupling agent Si-69, add 70g of naphtha and 30g of absolute ethanol mixed solution, after stirring, ultrasonically disperse for 40min to form a dispersion, add 400g of room temperature vulcanized silicone rubber Dow Corning 184 to the dispersion, Stir magnetically at room temperature for 6 hours to form a viscous mixed solution, place the mixed solution in a vacuum drying oven at 70°C and dry for 25 minutes to remove air bubbles and incompletely volatilized nap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com