Gas turbine combustion state parameter monitoring system based on TDLAS technology

A combustion state and gas turbine technology, applied in gas turbine engine testing, jet engine testing, engine testing, etc., can solve the problems of complex composition of combustion state monitoring system and low measurement accuracy of state parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

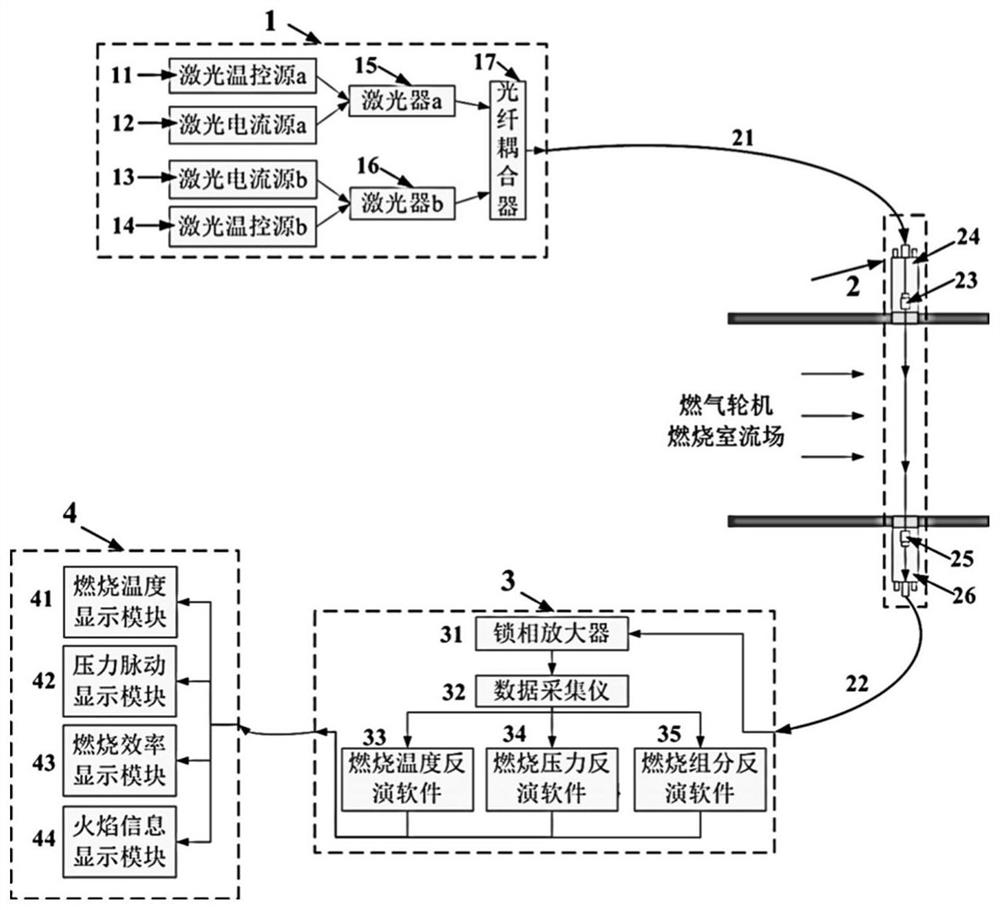

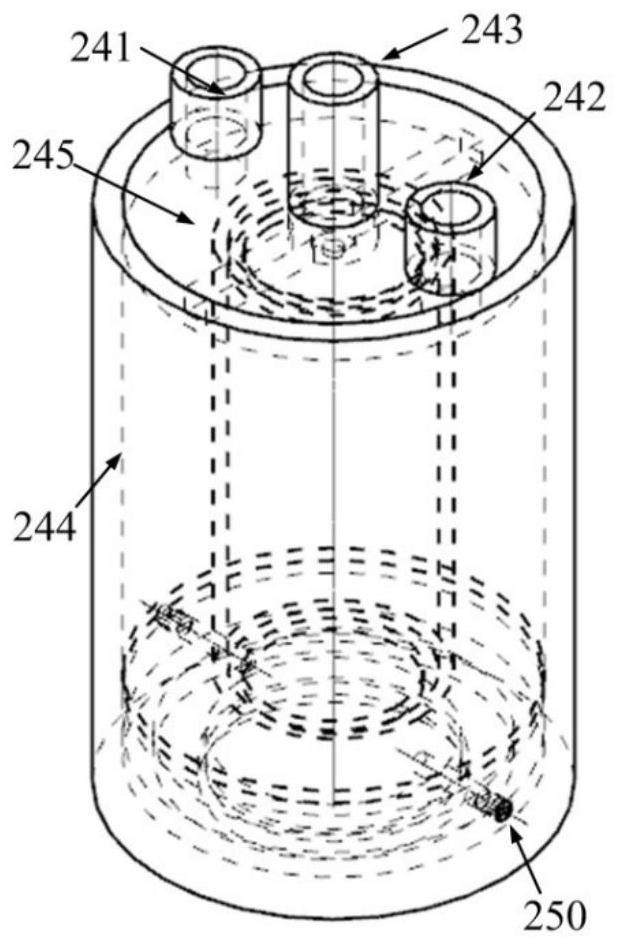

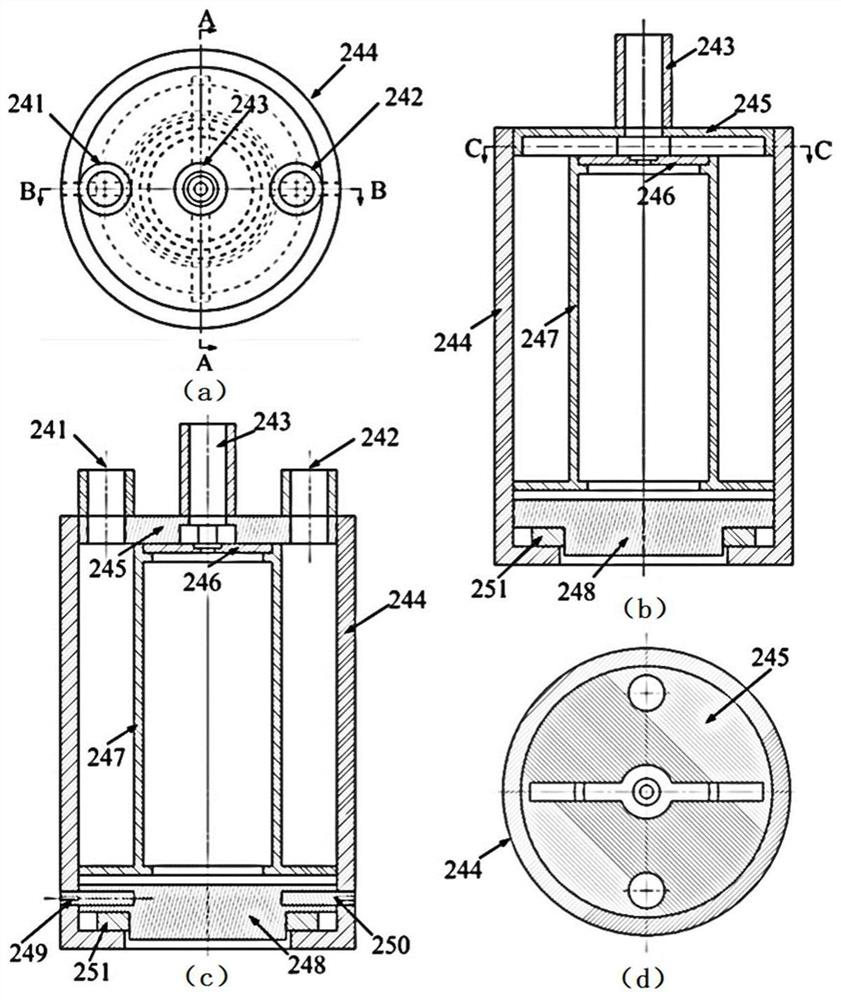

[0048] Such as Figure 4 As shown, when the combustion chamber of the gas turbine is working, the laser emission module 1 and the laser data analysis and processing module 3 are arranged at the far end of the gas turbine, and the laser collimator 23 and the collimator cooling sleeve 24 are installed at the upper end of the outlet of the combustion chamber of the gas turbine. The distance between the axis of the laser collimator 23 and the exit plane of the flame cylinder is 100mm, the photodetector 25 and the photodetector cooling sleeve 26 are installed at the lower end of the outlet of the transition section of the combustion chamber of the gas turbine, and the center of the detection window of the photodetector 25 is The distance from the exit plane of the transition section is also 100 mm, and the laser collimator 23 and the photodetector 25 are both perpendicular to the gas flow direction at the exit of the transition section of the combustion chamber of the gas turbine. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com